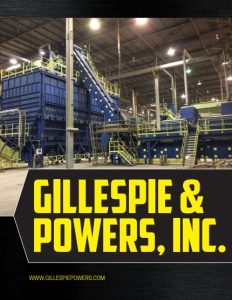

Gillespie & Powers, Inc.

Family-owned, globally-known

Business View Magazine interviews representatives from Gillespie & Powers, Inc, as part of our focus on suppliers of refractory products to the metal industry.

Gillespie & Powers of St. Louis, Missouri, designs, fabricates, installs, and maintains refractory-lined, high-temperature furnace equipment for the non-ferrous melting and hazardous waste industries. The family-owned company extends back to 1902, when Gillespie & Daly Construction, a brick and stone mason firm begun by John H. Gillespie, completed projects in the St. Louis area with bricks made from the area’s large, high-quality clay deposits.

At that time, the company also supplied the fire clay bricks that were used to contain the coal-fired boilers that provided heat and energy. Certain clay products are known as “refractory” materials, meaning they remain chemically and physically stable at high temperatures; thus their use in furnaces, kilns, incinerators, and reactors. Over time, the company began to specialize in boilers and high-temperature applications, then ultimately grew into the engineering and construction of high temperature refractory furnaces and systems.

At that time, the company also supplied the fire clay bricks that were used to contain the coal-fired boilers that provided heat and energy. Certain clay products are known as “refractory” materials, meaning they remain chemically and physically stable at high temperatures; thus their use in furnaces, kilns, incinerators, and reactors. Over time, the company began to specialize in boilers and high-temperature applications, then ultimately grew into the engineering and construction of high temperature refractory furnaces and systems.

Early in 1938, Charles A. Gillespie, son of John, H., united with Frank X. Powers to create Gillespie & Powers Inc. At that time, the city of St. Louis banned the burning of soft coal, which necessitated the conversion of boilers to use either gas or oil. So, the company designed the refractories that could do that, and, for many years, it continued to provide masonry installation services for heating systems and electric generator stations.

It was in the 1960s that, as a result of providing refractory repair services to a number of aluminum clients, the company expanded into the aluminum industry, beginning with refractory rebuilding services and culminating in the design, fabrication, and installation of aluminum melting and holding furnaces. The company’s management was also transferred to the third generation – John R. Gillespie, nephew of Charles A., was named president of the company in 1966, and in 1968, Charles K. Gillespie, son of Charles A., came on board as a partner and vice president. From that time, the two managed the company through more stages of growth and prosperity.

Another generation, the fourth, took its place in the mid-2000s, after John R. died and Charles K. retired. Jon R. Gillespie, the son of John R., who joined the company in 1980 as a brick mason after receiving his degree in mechanical engineering from St. Louis University, was named president. Today, Gillespie & Powers is run by Jack B. Gillespie, son of Jon R., and his cousin, John Peterman, who bought the company from Jack’s dad, in September 2017.

Today, Gillespie & Powers has about 75 employees,  including engineers, field supervisors, and office support. Its head office remains in St. Louis where it maintains its refractory masonry construction activities, as well as the aluminum industry segment, including the design and installation of melting and scrap preparation equipment. In addition, the company has masonry construction field offices in Hannibal, Missouri; Lewisport, Kentucky; Davenport, Iowa; and, most recently, Muscle Shoals, Alabama.

including engineers, field supervisors, and office support. Its head office remains in St. Louis where it maintains its refractory masonry construction activities, as well as the aluminum industry segment, including the design and installation of melting and scrap preparation equipment. In addition, the company has masonry construction field offices in Hannibal, Missouri; Lewisport, Kentucky; Davenport, Iowa; and, most recently, Muscle Shoals, Alabama.

Most of the company’s current clientele is in the secondary, or recycled, aluminum market. “Aluminum is the second most recyclable product next to lead,” Peterman notes. “And we design and build aluminum melting and handling equipment for the aluminum and non-ferrous industry, which is broad – the U.S., China, South Korea, Brazil, Mexico, Canada, Japan – we’ve serviced all those markets. “We also just finished a large project in Saudi Arabia,” says Sales Director, Ian Marsh. “We cover the entire world,” Jack adds. “We’re family-owned, globally-known.”

Peterman believes that Gillespie & Powers laps its competition in the sector because, unlike his company, they don’t “get dirty.” “Our competition will design it, and then hand it over to contractors to build and assemble, and they may show up when it’s turned on,” he states. “Everybody here is hands-on. We’re unique because we have our construction side. We will, design, fabricate, and build. It never leaves our hands. We take it from day one and hold it until we hand it over to the customer.”

“We also offer the refractory engineering side of it,” offers Marsh. “And because we’ve been in refractory for so long, we talk to the refractory manufacturers, and what we learn in the field gets passed back to them, so that they improve their products as we improve ours.”

Going forward, Peterman says this fifth generation at the helm of Gillespie & Powers is planning on expanding the company’s products, offerings, and geographic footprint. “We’re also planning on expanding into other markets, – steel, glass, copper,” he reports. “Currently, we deal in waste incineration, but we want to expand our services. Right now, we are in a two-hundred-mile radius of our home office, but we’d like to expand that further. We also plan on doing several acquisitions of some competitors. And we are always doing research and development and working on future patents.”

“Everything we do, we stand behind 100 percent,” Peterman declares in summation. “That also distinguishes us from our competition. We value our relationships and our legacy relationships to the point where we view them as partnerships and not a vendor/owner relationship. That shows in our work. So, we’re going to continue to focus on growing without jeopardizing our quality.”

Check out this handpicked feature on RE/MAX Select Realty – A culture of caring.

AT A GLANCE

WHO: Gillespie & Powers, Inc.

WHAT: A company that designs, fabricates, installs, and maintains refractory-lined, high-temperature furnace equipment

WHERE: St. Louis, Missouri

WEBSITE: www.gillespiepowers.com

PREFERRED VENDORS

United Refractories, Inc. – United Refractories Inc. manufactures concrete products and clay alumina monolithic refractories, including: castables, gunning mixes, shotcrete products, mortars, and pre-cast shapes for the steel industry. The company also supplies welding services to the cook oven and glass industry. It is based in Warren, Ohio. – www.urc4u.com

BDC, Inc. – BDC, Inc. distributes industrial combustion and process control equipment, such as actuators, vibration isolation and seismic restraints, burners, burner controls, data acquisition, flow meters, fuel standby systems, gas regulators, heat exchangers, pressure transmitters and switches, process control, recorders, temperature transmitters, valves, spark plugs, flame rods, temperature controls, and flame supervision controls. The company also provides field services, emergency service, preventative maintenance, inspections and testing, instrument calibration, and efficiency analysis services. BDC, Inc. was formerly known as Brandwine Equipment Co. and changed its name to BDC, Inc. in 1976. BDC, Inc. was founded in 1946 and is based in St. Louis, Missouri with an additional office in Kansas City. – www.gobdc.com