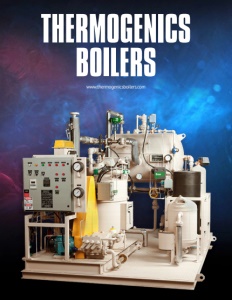

Thermogenics Boilers

Intelligent steam

Business View Magazine interviews Bryan Heppell, President of Thermogenics Boilers, for our focus on the boiler, heat exchange, and combustion equipment industry.

Based in Aurora, Ontario, Thermogenics Boilers is an industry-leading manufacturer of industrial coil tube boilers for industrial and commercial applications. Among the company’s offerings are coil tube steam boilers, heat recovery products, packaged deaerators, coil tube hot water products, coil tube thermal fluid heaters, ST series steam generators, blowdown tanks, packaged condensate systems, and pumps.

Thermogenics Boilers also provides oilfield steam generators, coil tube boiler parts and services as well as boiler rentals. An innovator in the boiler industry, Thermogenics equipment is utilized in food and chemicals processing, healthcare, process steam and heat, corrugated and paper processing, brewing and distillation, gas and oil processing, waste water treatment, valve testing, and marine applications.

Founded in 1975 in Concord, Ontario, as a service company for coil tube boilers, Thermogenics Boilers wisely paid heed to suggestions for improvements that came from its customers and service people in the field. In 1980, the company incorporated those improvements into a new boiler design that marked the beginning of an impressive growth trajectory for Thermogenics Boilers. The first Thermocoil boiler came off the shop floor in 1982 and proved to be very reliable. In fact, that original boiler is still in operation today. After producing steam for 20 years at a rubber manufacturing facility in Toronto, it was repurposed for use by a company in the UK where it now operates in a steel mill – proof that Thermocoils have a strong “shelf life” and travel well!

Bryan Heppell is currently President of Thermogenics Boilers and has enjoyed a long tenure with the company. He recalls, “In 1982, I was selling boiler feed pumps for Smart Turner Pumps and had all the OEM boiler manufacturers as customers. That’s how I met Thermogenics. They were growing fast and continued asking me to join the company. In 1987, they built a new plant in Aurora, near my residence in Newmarket, and a year later I decided it was time to go to work for them.”

The primary market for the company’s equipment is North America, but Thermogenics Boilers has supplied boilers to South America, Russia, and England. The company headquarters and manufacturing facilities (including an engineering department) are located in Aurora, with well qualified service operations in Cincinnati, Chicago, and Ottawa. According to Heppell, “Our typical customers include: institutional (hospital, universities, colleges); pharmaceutical; food and beverage manufacturers; and other industrial applications. There are a lot of manufacturing processes that require steam. We supply small businesses, right up to major multinational operations, and government contracts.”

While there are many boiler manufacturers in the world, surprisingly, there are few coil tube boiler manufacturers, and Thermogenics Boilers is very successful in that particular niche. Heppell explains the difference between the two types of equipment: “A coil tube boiler has a very small operating content of water. So, there is no potential energy there that would allow a crack in a tube to cause a catastrophic event. Many conventional boilers have thousands of gallons of water inside, and if it a crack develops in the pressure vessel, the potential energy of the water and steam flashes to atmosphere and that can be extremely dangerous.” In fact, several North American jurisdictions allow the use of coil tube boilers without the requirement of stationary engineers.

On the innovation front, Heppell says, “We manufacture our own burners, and the technology in that is always changing because of emission rules and regulations. So, we’re always trying to develop a better product that will burn at lower emission levels. We’re always improving controls, but the main design of the boiler hasn’t changed dramatically since the first design. Material-wise, it’s still made of steel.” As for cost, while decades ago coil tube units were expensive to produce compared to conventional boilers, the increasing price of steel has substantially narrowed the gap.

Thermogenics Boilers does a lot of training, especially for its service people. Gas technicians are hired right out of trade school and taught almost all of the operations in the shop: unit assembly, wiring, working in the test bay. Training takes up to two years before they are qualified as service technicians to work in the field on Thermogenics equipment. Heppell admits, “There is a shortage of skilled labor across much of North America, so we’ve had to come up with our own in-house training program. Many of our team have been here a long time. I started in 1988 and have five colleagues who were here before me. Now we’re much bigger and it’s still a great place to work.”

Networking is done at trade shows throughout the year, such as ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers). Thermogenics Boilers is also a proud member of the ABMA (American Boiler Manufacturers Association) and the Canadian Boiler Society as well as the Canadian Healthcare Engineering Society.

Portable Steam

Thermogenics Boilers products and service capabilities have a broad reach across North America and include significant project and service work with many notable Food & Beverage, Institutional, and Manufacturing organizations. In addition to more traditional steam, hot water, and thermal fluid applications, the company has been successful expanding its applications reach. Heppell says, “We manufacture high-pressure steam boilers that can go up to 2,850 psi, not many companies do that. We have seen significant opportunity in applications such as valve test operations. Valve Test companies require specialized steam boilers to provide valve fleet testing services to the Oil & Gas sector and play a key role in quality assurance and compliance for that sector. The industry needs to maintain its equipment at a high standard and as such, it was a perfect fit for Thermogenics’ skilled, factory-trained service technicians to service these boilers. As we are also able to supply new boilers, we can offer both an operating and capital solution to suit each customer’s individual requirements”

The continued development of the company prompted some preliminary succession planning to ensure it was well positioned to continue its growth in the future. “In 2015, we began to seek new partners for the business,” Heppell notes. “Due to Thermogenics’ reputation and recent successes, numerous interested parties presented themselves and, in 2016, Ironbridge Equity Partners became part of the Thermogenics family.”

“Our company’s tagline, ‘Intelligent Steam,’ came out of the fact that Thermogenics doesn’t just manufacture the boiler, we manufacture the whole boiler room and back up our products with a strong service network,” Heppell says, in conclusion. “We also have a rental fleet for new plant or expansion projects. Every application is different, and you have to know what that steam is being used for to intelligently put a plan together that addresses the full boiler life cycle.”

Check out this handpicked feature on XYMOGEN – A lot of things happening.

AT A GLANCE

WHO: Thermogenics Boilers

WHAT: Industrial coil tube manufacturer

WHERE: Aurora, Ontario

WEBSITE: Visit Website

PREFERRED VENDORS

McRae Engineering Equipment Limited – www.mcraeeng.com

Supplying manual & automated valves, as well as boiler level gauges, to Thermogenics for over 30 years.

Since 1930, McRae Engineering Equipment Ltd. has been supplying Canadian industries with top-of-the-line valve assemblies and Dresser-Rand now Siemens Steam Turbines. We expanded our product line over the years to include such manufacturers as Tranter, CMS & Hering heat exchangers, Unitorq pneumatic actuators, Gardner Denver Regenerative Blowers, Vacuum Pumps & Centrifugal Blowers, Universal silencer & filters, and many other process equipment and control solutions.