North American Die Casting Association (NADCA)

The voice of the industry

Business View Magazine interviews Stephen Udvardy, President of the North American Die Casting Association (NADCA), for our focus on the Die Casting Industry.

The North American Die Casting Association (NADCA) represents the voice of the die casting industry and is committed to promoting industry awareness, domestic growth in the global marketplace, and member exposure. Headquartered in Arlington Heights, Illinois, the Association is comprised of both individual members and corporate members located throughout United States, Canada, and Mexico.

Members of NADCA receive monthly magazines and e-newsletters on industry events and technical updates, die casting design assistance, discounts on publications and services, access to sales leads, and exposure to OEMs. Most recently, North American Die Casting Association has completed a searchable die caster database, containing more than 500 domestic die casters that can be filtered by name, region, materials, and casting sizes. The highest density of die casters is in and around the Midwest, with pockets in the Southeast, and the west and east coasts.

NADCA President, Stephen Udvardy, recently spoke with Business View Magazine about current challenges and topics of concern for companies in the die casting industry, and the benefits of NADCA membership. The following is an edited transcript of that conservation.

NADCA President, Stephen Udvardy, recently spoke with Business View Magazine about current challenges and topics of concern for companies in the die casting industry, and the benefits of NADCA membership. The following is an edited transcript of that conservation.

BVM: When was North American Die Casting Association founded and what mission does the Association fulfill?

Udvardy: “In 1989, NADCA became a non-profit corporation in the state of Illinois, formed from the Society of Die Casting Engineers (SDCE) and the American Die Casting Institute (ADCI). One was an educational branch, the other more of a technical entity, and it made sense to combine them into a single organization. Today, we’re the sole die casting association in North America.

“Our mission is to be the world leader and resource for stimulating continuous improvement in the die casting industry. Our mandate is to represent the industry and provide the membership base with education, training, and technical resources. We conduct R&D projects to advance the state of technology in die casting and keep our constituents competitive, worldwide. We produce surveys and stats, assist with marketing for die casters and suppliers to the industry, respond to questions from our membership, and we also employ a lobby office in Washington that keeps us abreast of regulations, trade issues, and things of that nature.”

BVM: Is advocacy one of your services?

Udvardy: “Yes. Tariffs have been at the forefront with our members and we try to stay proactive with the issue. We’ve done various communications trying to explain the current tariffs to the industry because it can be confusing. We recently conducted a survey to see what exposure our member companies have, in terms of the 301 China tariffs, as well as what type of cost and delivery impact people are seeing with the 232 aluminum and steel tariffs.

“Regarding NAFTA (North American Free Trade Agreement), we keep members apprised of what’s happening, and when there’s an opportunity to provide a position, the Association does that. In fact, we provided letters of opposition, as well as testimony, through one of our members, to the Department of Commerce when there were hearings on the aluminum and steel tariffs.

“When we see onerous regulations that don’t make sense for our industry, we may write letters to the EPA, or OSHA, if it’s a safety-related issue. Because, often the regulations apply to manufacturing in general or are targeted at a specific section of manufacturing, but die casting gets pulled into it where it shouldn’t. Here’s a concrete example: Companies that produce metal, whether primary or secondary smelters, may have a large amount of emissions, so a standard came out and die casters were part of the population that the regulation was targeted at, but most die casters don’t smelt, or make their own alloy. They buy it and simply re-melt it for casting. When we explained that situation, we were able to get an exemption for a large portion of our industry. That precluded companies from having to do a very expensive stack of emissions analyses.”

BVM: How do you communicate with membership?

Udvardy: “We have two levels of membership. There are a couple hundred corporate members, and we also have individual members – the price for them is lower but so is the benefit level. Corporate memberships get the highest level of benefit as far as services, discounts on publications, education, and training. Non-members pay the list price on all our saleable items, education and training. Individual membership is around 3,000, and that number has stayed fairly steady over the years. Some people decide not to renew, and different people become members. You lose some and gain some.

“Avenues of communication include electronic, via email and our extensive website, and hard copy mailing. We send out a weekly e-newsletter, and special emails and hard copy mailings, depending on what information we’re trying to get out, such as press releases. We have a distribution of key contacts at all of the die casting plants and our die casting supplier member companies.

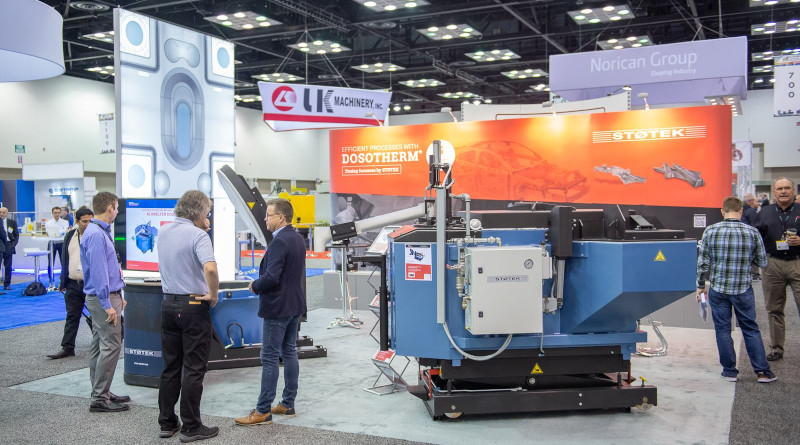

“In terms of networking, we have annual conferences – an Executive Conference, Plant Management Conference, and a trade show which is our Congress. We have a larger trade show every three years and a smaller one the two years in between. Our large show, where robotics and machine manufacturers actually bring equipment, was held at the Indiana Convention Center in Indianapolis this year and will be again in 2021. The show in between, our Congress and Table Top Exposition, changes geographic location. Next year it will be in Cleveland, Ohio.”

BVM: What challenges and changes do you anticipate happening in the industry over the next few years?

Udvardy: “Changes in technology will continue and two main areas are productivity and overall cost, so, becoming more energy efficient. That is probably the best way to stay world-competitive. If you don’t have a niche market that can command a higher price and profit margin, then it has to come from increased productivity. One of the emerging technologies that can assist in that area is with smart machines and machine learning.

“We continue to look at what alloy changes we can make to produce a higher performance end casting. Typically those are smaller, incremental changes. Anything to make the mold that produces the die last longer or draw heat out more quickly to solidify the molten metal faster is beneficial; also, producing ever-increasing geometric complexity and thin walls. The thinner the walls, the less metal is utilized, hence less metal melted, and less energy consumed.”

BVM: Does the Association have any new initiatives planned?

Udvardy: “Yes, we’re working on something we’ve not offered in the past – an Association health plan. It would be through a third-party broker, but when we look at issues that come through the industry, certainly, healthcare costs are one of those. North American Die Casting Association feels if we can assist in providing alternatives that might result in lower insurance premiums for our member companies, we’re happy to do that. So, that is currently under study.

“Something else we’ve done differently this year is allowed plants to provide proposals to NADCA for research and development projects. Most of the R&D projects we’ve conducted in the past have come through our technical committees or from outside funding sources like the Dept. of Energy and Dept. of Defense. NADCA, being a non-profit organization, tries to garner as much federal or outside support for R&D as it can. Currently, the Dept. of Defense provides the largest funding source for our research projects. NADCA has some funds, as well, that it uses for its own projects.

“A lot of companies with very talented and intelligent individuals may not be able to participate in our committees routinely but might have ideas for conducting research projects. So, it’s a way to try to get more participation from industry, and ideas on what’s important to plants to resolve certain issues or continue to advance specific technologies in the overall die casting process.”

BVM: How would you sum up the importance of North American Die Casting Association to the die casting industry?

Udvardy: “We’re here to help the industry and act as its voice in North America. NADCA offers a wide variety of products and services that not all our members and non-members are fully aware of, so, we’d like to encourage the industry to look at getting the full benefit of what their Association has to provide.

“A company may be a corporate member because they intend to take a lot of NADCA courses and want to get the best discount they can. They’re aware of education and training, but because they’ve got that specific reason, they may not understand that we have a very active research and development program. We have a strategic plan and road map for R&D that’s published on an annual basis, and anywhere from 13 to 16 active research projects at any one time. And they may not be aware of our voice in Washington. People join NADCA for different things, and it’s typically not because they’re aware of everything we do. We want members to take advantage of all we have to offer. Together, we make a difference.”

Check out this handpicked feature on Nationwide Boiler Inc. – Integrity, dependability, real customer service.

AT A GLANCE

Who: North American Die Casting Association (NADCA)

What: Trade association for the die casting industry in North America

Where: Arlington Heights, Illinois

Website: Visit Website