The International Cast Polymer Association

Moving forward with forward thinking

The International Cast Polymer Association (ICPA) is a nonprofit trade association made up of manufacturers, suppliers, fabricators, and installers of cultured marble, cultured granite, and solid surface kitchen and bath products, which are made using the cast polymer process. The ICPA is dedicated to promoting recognition and demand for the industry’s products, supporting member companies on legislative and regulatory issues, and maintaining high standards of quality in cast polymer products.

The International Cast Polymer Association began in the early 1960s, when a small group of manufacturers and a supplier met near Chicago to discuss common concerns and challenges facing them in the cultured marble industry. In the early 1970s, the Cultured Marble Institute (CMI) was formally and legally organized to share manufacturing techniques, which, over time, helped to greatly improve cultured marble products. The organization continued to grow and, in 1993, the association incorporated as the International Cast Polymer Association.

Like so many other industries, the cultured marble industry was adversely affected by the Great Recession. “There used to be hundreds of manufacturers of cultured marble throughout the United States, Canada, and Mexico in the early 2000s, when the industry was booming, and the demand for product was high,” says Jennifer Towner, ICPA’s Executive Director. “But, after 2008, the building market halted, the hospitality industry slowed, and many plants closed.” Because of this, the International Cast Polymer Association Board of Directors and the voting membership decided to form an alliance under the American Composites Manufacturing Association, (ACMA) as it was a more economical way to administer the Association.

As the economy improved, and the cultured marble industry began to grow again with increased demand for its products, the Association decided in 2015 to return to a member managed organization and incorporated as its own non-profit, 501(c)(6) entity as the International Cast Polymer Association – now referred to as the “new” ICPA. From 14 manufacturer members, the new International Cast Polymer Association grew quickly to today’s total of 81 members, two thirds of which are manufacturers of cultured marble, granite, and solid surface products, with the remaining number being, suppliers, distributors, and affiliates.

“The International Cast Polymer Association exists to enhance the cast polymer industry and we do that by training, education, and networking,” says Towner. “We have programs to support our manufacturers; maintaining a consistent quality standard throughout the industry is very important. Plant safety is another key issue and we are developing a safety program that will be available to our manufacturing members. We have best practices seminars and webinars, and there is a great deal of valuable technical and educational resources on our website. The International Cast Polymer Association partners with the ACMA to provide our manufacturers support with regulatory and governmental issues.”

“Our manufacturers talk to each other frequently, but wanted to talk even more,” Towner continues. “So, we developed a group forum page, Talk ICPA. Members can log onto that page and ask questions, and another member can read that and respond. There’s also been a great need for buying and selling equipment because many of our manufacturers are streamlining; they can post that they have equipment to sell, on the forum page, or if they’re looking for a particular piece of equipment to buy.”

“We publish a quarterly magazine called Cast Polymer Connection, and I also publish a monthly electronic newsletter. We have an annual industry convention event called POLYCON. It’s an opportunity for manufacturers to get together. Suppliers and distributors bring their new products to display; we have breakout sessions and round table discussions, and hands-on plant demonstrations” In 2019, POLYCON will be held in Kansas City on April 10th-12th.

Towner goes on to explain that the Association keeps up with some of the new trends in the cast polymer sector. For example, “Many of our manufacturers are moving toward specializing in one area; they’re focusing on residential homebuilders, or commercial building, particularly hospitality – many do not do both. Some specialize in one particular type of cultured marble such as tile, or one type of product such as vanity tops, shower basins, shower panels, or window sills. They find that if they do one thing really well, and just produce that product, it can be more profitable for them. So, many of them are becoming very specialized.”

“There’s also a move toward automation and robotics,” Towner adds. “The technology is out there to help improve production and finished products. At the same time, it is increasingly difficult to hire and keep skilled people who want to work in manufacturing. How manufacturers market their products is changing, as well. Most of our manufacturers still have showrooms, but they’re using the internet and more interactive websites to display their products, so buyers can get a really good, three-dimensional look at them.”

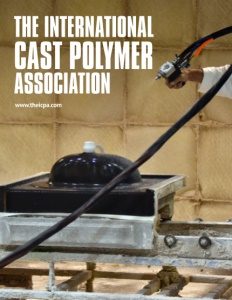

Two of the most popular and widely manufactured cast polymer products are cultured marble, stone, and tile, and solid surface products. Cultured marble, stone, and tile is a precise blend of polyester resin, catalyst, fillers, and pigments that are mixed together thoroughly and then cast, or placed, into polished molds that have been coated with a clear gel-coat. The gel coat is formulated to achieve a tough, durable, waterproof, non-porous, and transparent surface which is very resilient and easy to maintain. The gel coat can also provide a glossy surface to the final product. The chemical reaction initiated by the catalyst causes the resin to become polymerized and harden, bounding the entire matrix together in a hard, strong mass. After several hours of chemical curing, the product is removed from the molds and trimmed, ground, polished, and inspected for any flaws. Cultured marble, stone, and tile is available in a host of colors and blended and veined patterns to compliment any décor in both residential and commercial buildings.

Two of the most popular and widely manufactured cast polymer products are cultured marble, stone, and tile, and solid surface products. Cultured marble, stone, and tile is a precise blend of polyester resin, catalyst, fillers, and pigments that are mixed together thoroughly and then cast, or placed, into polished molds that have been coated with a clear gel-coat. The gel coat is formulated to achieve a tough, durable, waterproof, non-porous, and transparent surface which is very resilient and easy to maintain. The gel coat can also provide a glossy surface to the final product. The chemical reaction initiated by the catalyst causes the resin to become polymerized and harden, bounding the entire matrix together in a hard, strong mass. After several hours of chemical curing, the product is removed from the molds and trimmed, ground, polished, and inspected for any flaws. Cultured marble, stone, and tile is available in a host of colors and blended and veined patterns to compliment any décor in both residential and commercial buildings.

Solid surface products consist of resin and filler but without a surface gel coat. Solid surfaces require a resin with higher strength and heat resistance. Solid surface products have many of the same advantages of engineered or cultured products. However, they are typically manufactured in sheet form for fabrication into finished products. Solid surface can also be cast into a variety of shapes, including countertops, shower bases, and bathtubs. Solid surface products are available in colors and patterns including colored granules or specks that make the final product look like natural granite and stone.

“And they are excellent products, which is why the demand for the product is growing.” Towner states, emphatically. “They’re beautiful, they’re strong, they’re resistant to chipping and staining; they don’t cost as much as natural stone; they’re easier to install; they’re much safer because there’s no grout; they’re mold resistant; they’re easy to clean. And some of the manufacturers are doing some gorgeous designs.”

Towner also praises the Association members as hardworking and passionate about the products they make. “There’s much friendship and support among members,” she says, in conclusion. “There are several cases where a plant owner will travel distances to go into another person’s plant to help them with an issue or a problem and teach them how to make their product better, or how to streamline their manufacturing systems, or to share a new software system that better integrates their processes. The camaraderie and sharing of information are the greatest strengths of the Association.”

The ICPA – Moving Forward with Forward Thinking.

Check out this handpicked feature on The Columbia Machine Company.

AT A GLANCE

WHO: The International Cast Polymer Association

WHAT: A nonprofit trade association

WHERE: Arlington, Virginia

WEBSITE: www.theicpa.com/