BOS Innovations Inc.

Innovations in automation

Business View Magazine interviews Ben Huigenbois, President of BOS Innovations, Inc., for our series on Canada’s Fastest Growing Companies.

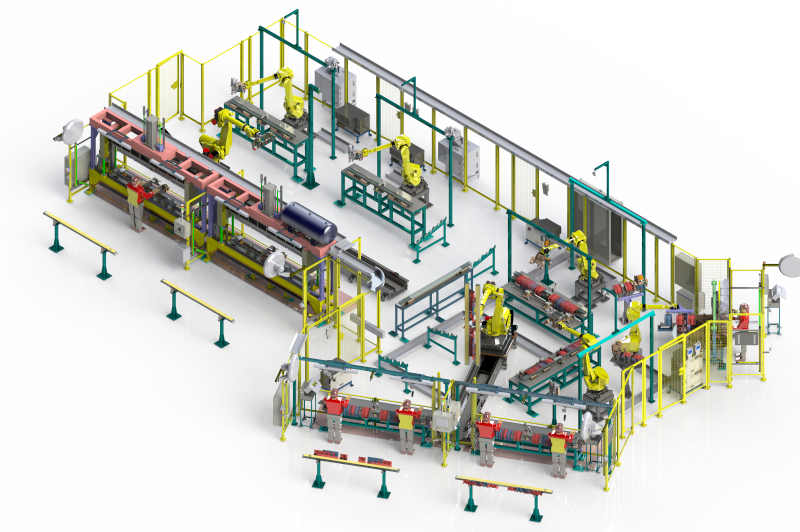

Today’s unprecedented demands of global competitiveness have made the challenges facing manufacturers more complex than ever. BOS Innovations Inc. helps companies deal with those challenges by providing factory automation solutions that increase productivity and profitability. For over 20 years, BOS has worked closely with manufacturers throughout North America to develop innovative, profit-driven solutions, including full services in machine building and integration of automation and robotics. Customers in a wide array of industries know and respect BOS for its impeccable quality and commitment to delivering what they promise.

BOS Innovations was founded in 1996 by Casey Huigenbos, a seasoned professional in the manufacturing sector with “a bit of an entrepreneurial spirit.” His understanding of automotive assembly equipment (a common industry in Ontario, at the time) was key to the success of what began as a fairly small business doing a lot of semi-automated assembly systems and some special purpose, very customized machines. In the year 2000, Casey’s son, Ben, joined the company as they began to develop the controls side of the business.

Ben Huigenbois, President

As Ben recalls, “In August of 2008, my dad passed away. It was rough, but we put our heads down and kept going. My mother, Joan, became more involved on the financial side and took over main ownership and we’re still a family business. We were about 15 people in 2008 – fairly small but with loyal customers in the area – mostly tier-two suppliers in automotive assembly for parts manufacturers. It was clear that the industry was changing; we understood that the traditional small assembly machines with operators weren’t going to exist for the long-term in Ontario. So, that’s when we kicked off a plan to bring more advanced technologies into the company, specifically robotics and (advanced) controls.”

In 2010, BOS launched robotic welding technology, followed in 2013 by the addition of laser technologies, which has become much more advanced over the years and now comprises a sizeable part of the portfolio. 2015/16 saw the company seriously develop its abilities in robotic vision guidance and vision control systems, as it became apparent that was going to be a prevalent technology going forward. More recently, BOS has made great strides with collaborative robots, as well.

Ben explains, “We use industrial robots that others manufacture. We have a good, long-standing relationship with FANUC Canada. We’re an authorized system integrator for them; sharing technology and working together to find solutions for our common customers’ problems. We have a similar, less formal, relationship with COGNEX – a newer tech provider with some exciting recent advances. And we also work closely with a number of other technology providers. We buy robots that come with hundreds of options for ways to deploy them. That’s where system integrators come in. The manufacturers build robots with lots of flexibility, but it’s up to the integrator to develop innovative solutions to the infinite number of problems you find in the industry. The robots come with built-in firmware and, using some of their software tools and some from the vision systems, our job is to make those systems talk to each other and the broader machine controls. We also have to make the robots talk to each other by integrating all the systems to work together.”

Broadly described, BOS is a service provider for manufacturers; a machine builder and a system integrator for such clients as automotive parts suppliers Toyota, Magna, and Ground Effects. Ben acknowledges that the recent GM announcement about plant closures in Canada is certainly affecting some BOS customers and could have trickledown effects, negatively impacting the industry in Ontario.

Retaining, training, and maintaining skilled workers is a challenge in this high-tech industry. BOS has about 95 employees with job skills ranging from systems engineering and mechanical controls designs, to software people, vision programmers, and all the skilled trades for building a machine, including millwrighting and fabrication, electrical, and panel building. They also have a complete tool and die shop. “We have the capability to do the entire machine,” says Ben. “We do outsource when we need certain special skills, or we need to augment our workforce. There’s a real skilled worker shortage. It’s very competitive these days. We recruit, and people try to recruit from us. It’s a common problem. Having a strategy to specifically deal with that is a priority in our company.”

When it comes to competition, the BOS difference is that it brings a full spectrum of capability to its customers, always focused on launching new technology and working in the background on advancements, so customers can integrate what they need into their next solution. Making sure they’re at the cutting edge of technology means having a highly motivated and talented team. That’s of prime importance. The company prides itself on being able to control and manage the entire project for the customer from end to end. Even if it means using contract resources, it controls the quality of the machine.

BOS operations are located in a 40,000-sq.-ft. facility in Dorchester, Ontario. Marketing the business is done, in part, with a social media presence, as well as involvement in networking within its technology community. Ben notes, “We also do a lot with multimedia, so people can see our product in action, which is the best thing to target the people in our industry. But our best business always comes from the relationships we have with our current customer base, either from retaining and continuing to grow with our customers, or by referral. In the last year, we’ve shipped a large volume of machines to Mexico, the U.S., and a significant amount has gone to China, as well.”

Involvement with industry organizations such as RIA (Robotics Industry Association) and the Association for Advancing Automation provides great networking channels. In addition, Ben credits several southwestern Ontario engineering schools (University of Western Ontario, University of Waterloo, Conestoga, and Fanshawe Colleges) for being good partners when it comes to recruiting and working with their co-op and intern programs. “Another organization we really love and support every year is FIRST Robotics,” says Ben. “It’s a high school robotics competition founded by Dean Kaman to ‘to inspire young people to be science and technology leaders and innovators, and foster well-rounded life capabilities including self-confidence, communication, and leadership.’”

As for what lies ahead for BOS, Ben shares, “Technology in manufacturing is moving extremely fast, so we’re creating technology solutions that we feel are best suited for that future. Whether it’s AI-driven, inspection-type systems, or inline dimensional inspection systems, or some of the more advanced robotics solutions that the industry is demanding. At BOS, our footprint will continue to grow globally in how we approach our customers and customer base. We know we need to be equipped to give them a higher level of support. Rather than just providing machines and integration, we have to help them develop solutions. That is a big focus of our future.”

Automation is all about creating efficiencies and new manufacturing possibilities. In most cases, even with delicate precision work, automation is possible. By partnering with the most technologically progressive companies, BOS Innovations and its highly skilled team are developing advanced automation that will help power the future of manufacturing and life as we will know it. This is why it exists and will continue to succeed as one of Canada’s Fastest-Growing Companies.

Check out this handpicked feature on COE Distributing – Tops in office furniture.

AT A GLANCE

Who: BOS Innovations, Inc.

What: Machine builder and system integrator for manufacturers

Where: Dorchester, Ontario

Website: www.bosinnovations.ca

PREFERRED VENDORS

CenterLine – www.cntrline.com

CenterLine (Windsor) Limited supplies standard and custom brand products and services satisfying spot and projection welding, metal-forming and cold spray application needs. Our industry leading configurable products such as pedestal welders, welding guns, nut detection systems and weld consumables assist our customers in maintaining their competitive advantage. .

ifm efector Canada Inc. – www.ifm.com/ca

Since 1969, ifm has developed, manufactured and marketed automation solutions to industries that include assembly and robotics, automotive, material handling, packaging, plastics and food and beverage. Ifm has enjoyed strong working partnership with BOS Innovations over the past several years and look forward to continued growth for both organizations.