Fisher Tank Company

Adapt and evolve

Business View Magazine interviews Paul Windham, President of Fisher Tank Company, for our focus on the Steel Tank Industry

“These are strange times for everyone,” says Paul Windham, President of Fisher Tank Company, referring to the challenges that companies are facing due to COVID-19. “The pandemic has slowed down various industries and businesses and forced everyone to adapt and evolve.” Evolving and adapting is the 72-year-old company’s strong suit. As the economy absorbs the COVID impact, Fisher Tank Company is doing what it does best – meeting and exceeding its customers’ needs for high quality carbon and stainless steel storage tanks. Fisher Tank remains committed to the company’s motto of “safety, quality and productivity, and in that order.” Windham emphasizes, “Although a lot has changed in the short term, we are a long-term thinking company, so we are here for the long haul.”

Fisher Tank Company’s history began in Chester, Pennsylvania in 1948. Joe Fisher, one of the founders, was working with Chicago Bridge and Iron at the time and noticed a gap in the market for quality welded steel tank repair services in the booming oil and gas industry of the Northeast. As a boilermaker himself, he had the technical knowledge required to undertake this venture. Partnering with Bob Borst, they incorporated Fisher Tank Company in 1951. Five years later, the company built its first welded steel standpipe in West Point, Pennsylvania; a 100-foot-tall standpipe holding 250,000 gallons of water.

In 1975, the company saw an opportunity to venture into the Southeast, which led to the opening of its South Carolina office, originally in Lexington but today in Leesville. Although it started as a one-person sales outpost, the location currently has a fabrication shop and an extended office with sales, engineering, and support staff. Windham recalls, “There were no refineries in South Carolina, so we diversified and got into the chemical industry; we did water tanks, industrial work – a whole host of different things.” The company soon opened two other offices, one in Cropwell, Alabama and most recently, in Atascadero, California.

Today, Fisher Tank Company is a leading, full-service, welded-steel tank fabricator and constructor with unmatched expertise working in a wide range of industries nationwide. Fisher Tank’s high level of specialization has helped the company differentiate itself from other service providers. “We design, fabricate, and field-construct carbon and stainless-steel tanks and vessels better than anyone else,” says Windham. “It’s all we do. One of our strengths is that we’re very diverse in the markets we serve, but with one major product. We build one thing, and that’s a field-erected welded-steel storage tank. We fabricate the parts and send them out to the field to get built by our boilermaker field crews.”

Underpinning this specialization is a combination of vertically integrated services the company offers that make it a full-service tank builder. These services include estimates, tank design, engineering, field construction, field painting, fabrication, and tank repairs and modifications.

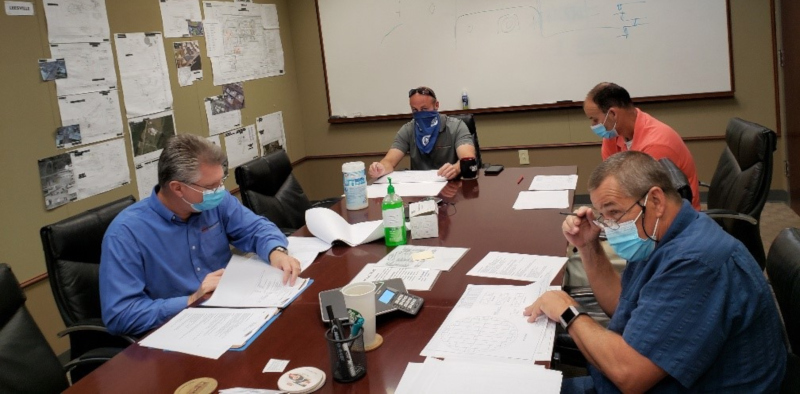

Fisher Tank is proud to operate under an ESOP (Employee Stock Ownership Plan) with about 100 employee owners staffing the company’s various shops and offices, and up to 200 boilermakers in the field. Although the company has a long history, it has maintained a small-company culture, reflected in its executive team’s combined experience. Windham has been with the company since 1979, and the previous president, Mike Szelak, who is now CEO and Chairman of the Board is a 52-year veteran of Fisher Tank Company.

The firm’s relatively flat organizational hierarchy has also played a role in helping the company remain “small” and specialized. Even though he is the President, it is not difficult for anyone in the company to approach Windham. If there is an operations issue in the field, it’s not unusual to find him or a Vice President on site, which is rare in the industry, especially among companies of a similar size.

During the COVID-19 pandemic, some projects have slowed down, particularly in the oil and gas industry. However, the diversity in the markets Fisher Tank Company serves has proven to be a significant point of resilience. While the energy sector has cooled down, other industries like chemicals have not. That has helped the company pick up jobs. “Landing a big job in the chemical industry has helped us retain our people and keep them busy during this time, considering we are termed as essential services,” explains Windham. “And we are completely debt-free. Because we had a good year last year, our cash reserves have grown, which has allowed us to maintain operations this year in the midst of all that’s happening.”

The company’s service charter – “Storage Tanks from Start to Finish” – is demonstrated in the ambitious projects the company has undertaken over its 70-plus years. While their focus is on designing and building tanks, the pandemic has occasioned a shift in strategy to focus more on tank repairs. Windham reports, “Although our clients may not want to invest in new tanks considering the current economic environment, they must repair their tanks to stay within their industry regulations. We are well equipped to support this kind of work and well positioned to help our customers keep their tanks in service and in compliance.”

Alongside this shift in focus (although the company is still open to design and build projects), serving a broad target market with a specialized service is also helping the company weather the current crisis. “While larger companies have multiple units that serve different needs in various industries,” says Windham, “our competitive advantage is that we can build complex tanks anywhere. For instance, we have a client in Houston, Texas, that requires a complex build. Although there are many tank builders in the area, we got the job because of our ability to handle complicated jobs very well.”

Every industry is experiencing a shortage of welders, but as a union-affiliated company, Fisher Tank has had the benefit of acquiring most of their field force through the union. On a related front, the firm has had to address some workforce challenges occasioned by the pandemic, primarily affecting its office staff. Windham acknowledges, “As a family-oriented company, we’ve had to support our employees while they work from home, since some do not have childcare at this time. A shortage of human resources has also pushed us to invest more in technology. Our quality control department is responsible for identifying any gaps in our processes and finding new technologies that can bridge the gap. We are always open to investing in new technologies if they can help us serve our clients better.”

When it comes to adjusting to the new norms, Windham offers the company’s perspective: “Fisher Tank Company is an old-school company, but we’ve adapted very quickly to the new way of doing business. Our business development staff, for example, have adjusted to doing their sales calls via phone, email, and virtual meeting tools like Microsoft Teams and Zoom.” The company recently participated in a virtual conference organized by the Steel Tank Institute, Steel Plate Fabricators Association (STI-SPFA). “We had an eight-hour seminar with people interested in buying tanks,” says Windham. “A conference that brought together all our major competitors in a unified effort to educate our customers. Although this year’s conference was not as well attended, the event continues to create strong partnerships for all participants.”

Looking from the past to the future, Windham adds, “We’ve been very successful for the past ten years, so our growth plan is to keep doing what we are doing and doing it better and better. With the current conditions, our major priority is to remain very consistent in the quality of service we provide while maintaining slow, sustainable growth.” Leveraging the company’s broad target market, Windham believes they are poised to bounce back as different market segments start emerging from the current lull. He emphasizes, “That is how Fisher Tank Company runs. Everything we do is not for this year or next year, but the five-year plan or even longer.”

AT A GLANCE

Fisher Tank Company

WHAT: A fabricator of field-erected, welded steel tanks

WHERE: Chester, Pennsylvania

WEBSITE: www.fishertank.com

PREFERRED VENDORS

G.C. Zarnas – gczarnas.com

Founded in 1948, G.C. Zarnas is a leading QS-1, QP-1, QP-2 and QP-8 national industrial painting contractor specializing in: the application of high performance & specialty coatings, tank linings, fireproofing, shop coatings & lead abatement. Our experience with various corrosion-resistant systems enable us to recommend optimum solutions. Safety is our top priority as evident by our low Experience Modification Rate (EMR). Our field personnel – highly skilled in surface preparation, application techniques, quality control & safety – follow through on every detail of your project. gczarnas.com