The Schaefer Group

Innovation and invention

Business View Magazine interviews David White, National Sales Manager of the Schaefer Group, as part of our focus on the industrial furnace sector.

In 1930, Frank W. Schaefer founded a refractory sales and service company, making calls to Ohio buildings to refit and relight their boilers. Over the past 88 years, The Schaefer Group has grown into a leading international industrial furnace builder. From recognizing market shifts to harnessing the power of technology, the company not only navigated its way through the 20th Century, but is prospering well into the 21st.

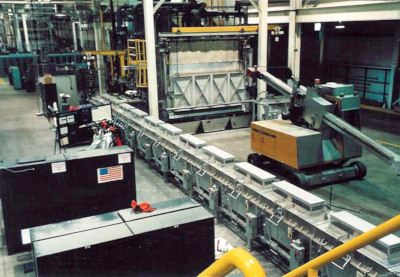

The beginning years of The Schaefer Group saw growth and success in tandem with the rise of the steel industry. By 1945, upon the requests of its clients, The Schaefer Group began to design and build their own furnaces. Success followed, and the firm has since grown into a leading furnace manufacturer and service provider, offering turn-key service that includes design, construction, installation, complete technical support, and maintenance.

The beginning years of The Schaefer Group saw growth and success in tandem with the rise of the steel industry. By 1945, upon the requests of its clients, The Schaefer Group began to design and build their own furnaces. Success followed, and the firm has since grown into a leading furnace manufacturer and service provider, offering turn-key service that includes design, construction, installation, complete technical support, and maintenance.

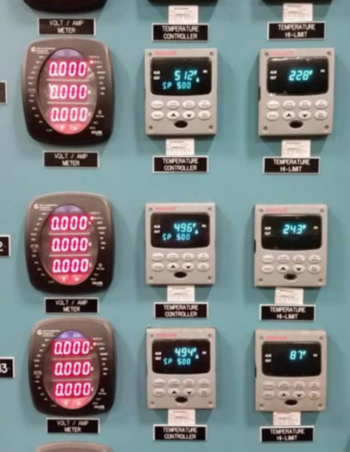

Today, The Schaefer Group is comprised of three divisions: industrial furnaces; refractory sales and services; and Delta Control, a recently purchased programming firm that integrates major systems with their controls. The company manufactures within a 95,000-square-foot facility in Beaver Creek, Ohio, just east of Dayton, and employs between 75 and 95 individuals, depending upon demand. With two satellite locations in Perrysburg, Ohio and Louisville, Kentucky, the firm stays busy and available. According to National Sales Manager, David White, “The last four years have been the busiest years in my 38-year history with the company.”

White attributes the company’s continued growth and success to innovation and invention, explaining, “We pioneered several things through the years. We were the first company to invent a molten metal trough system. The first one was gas, but within two years we changed to electric for quality. We invented the electric radiant roof melting furnace in 1971, and we’ve been building them ever since. We are the only company that has a working molten metal valve. We were the first company in North America to invent a regenerative burner system for Chrysler. And we were also the first to use three-component refractory linings in our surfaces.”

Explaining the company’s drive to innovate and develop, White simply states: “We decided the industry standard wasn’t enough.” The Schaefer Group is not only raising industry standards, it’s setting the bar for future development, and technology will play a huge role in the company’s next endeavors. White explains a new project: “We are implementing control systems that will allow us to monitor client systems, if they want, and notify them of any issues. Remotely, we will be able to see whether systems are experiencing overcharging, over combustion, etcetera.” He acknowledges client privacy and autonomy though, recognizing that, “Not everyone is going to want that, but we are going to offer it as an option on many of our furnaces.”

Just as the company is planning to invest in product safety and security, it is also sourcing another type of technology to ensure employee safety. “We have just started getting into virtual reality for our furnaces,” explains White. “Everyone is concerned about safety in the molten metal industry. So, rather than take new guys out on a floor and put them in front of a hot furnace to teach them how to clean it, we can do so using VR.”

“We can take a 3-D drawing of a furnace and create a virtual reality of it so someone can put the glasses on and look at it,” he continues. “If the client has a 2- or 3-D plant layout, we can actually set a furnace into the VR layout to make sure everything has clearances and understand how it works in its proposed location.”

The Schaefer Group won’t just follow the virtual path into the future, though. White gets back to the basics: “We’re always looking for ways to save energy, better insulate and employ better technology. We’ve done a lot with immersion element furnaces where we have electric elements right down in the bath surrounded by a tube. I think in the future, we’ll be melting that way with electricity. It will take a little more space, but if we can melt at 75 to 80 percent efficiency as opposed to 68 percent as we do now, that would be a huge benefit.”

As the firm focuses on its future, filled with ever-changing technologies and improvements, it recognizes a singular constant over time – the Schaefer Group’s experience, knowledge, and dedication to innovation are all the result of its people. According to White, “Our mission statement states that the most important resource The Schaefer Group has is people.”

As the firm focuses on its future, filled with ever-changing technologies and improvements, it recognizes a singular constant over time – the Schaefer Group’s experience, knowledge, and dedication to innovation are all the result of its people. According to White, “Our mission statement states that the most important resource The Schaefer Group has is people.”

Describing the company’s ethos, he states, “We are a family-owned company. The owner, Dick Schaefer, is Frank Schaefer’s son, and cares greatly about our employees.” But appreciation doesn’t stop there. “We also treat our customers like family. Our goal is to help people more than it is to make money. We treat a process or a problem first, and then make money.”

This dedication to people has not gone unnoticed. “We have an excellent reputation in the industry,” exclaims White. “There are very few people in North America who don’t know who The Schaefer Group is. It’s because of our reputation and longevity.”

The organization undoubtedly knows it has a good thing going. Once again, White puts it simply: “We are driven to produce the highest quality and the most efficient furnaces we can. And I think we do a pretty good job at that.”

Check out this handpicked feature on Buckles-Smith – Industrial automation, electrical supplies.

AT A GLANCE

WHO: The Schaefer Group

WHAT: A furnace manufacturer and service provider

WHERE: Dayton, Ohio

WEBSITE: www.theschaefergroup.com