Tazewell Machine Works

Not too big, not too small

Business View Magazine interviews Mack Cakora, President of Tazewell Machine Works, as part of our focus on the aluminum foundry and casting industry.

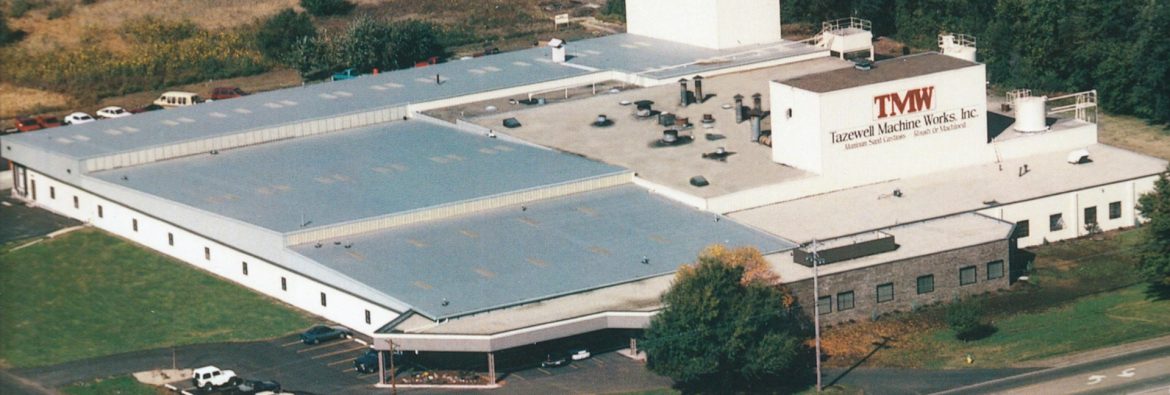

Pekin is a quaint little blue-collar town nestled right in the heart of central Illinois, about halfway between Chicago and St. Louis. It’s also been the home of Tazewell Machine Works, manufacturers specializing in complex rough and machined aluminum sand castings, for the last 75 years. “My grandparents came to Pekin in 1938,” recounts Mack Cakora, Tazewell’s third-generation part owner. “My grandfather, Henry F. Cakora, worked at a machine shop here in town called Excel Foundry & Machine until he made the decision to go out on his own. He had only an 8th grade education, so he was a self-taught, self-educated individual. In 1945, he bought an auto repair garage and started his own machine shop. Because he was having to go to other foundries to get castings to machine, a few years in, he decided he’d start making his own castings. Tazewell started out as a small brass foundry, but it became a non-ferrous foundry, pouring both brass and aluminum castings and machining them. By 1963, the facility was up to 20,000 square feet. My grandfather ran the foundry and machine shop operations while my grandmother, Blanche, took care of the office and the books. In July 1963, a fire destroyed that facility and it was rebuilt elsewhere in Pekin.”

Owner, Mack Cakora

“We decided, in 1973, to get out of brass in order to make the operation more efficient,” Cakora continues. “At that time, Caterpillar was, for all practical purposes, our only customer. We had picked up a few others, but Caterpillar represented over 90 percent of our business. When they started outsourcing the machining on aluminum castings, we decided to get back into it. So, from 1979 until the present, we’ve operated as an aluminum sand foundry and a machine shop.”

Today, Tazewell employs 49 people and operates out of a 116,000-square-foot facility. Its management team has over 248 combined years of service experience and a proven track record of high-quality castings at competitive prices. “We run castings anywhere from under a pound all the way up to 320 lbs. With few exceptions, any casting we make, we can machine. Most of our customers do their own machining, but we’re able to offer full-service, value-added services such as chromating, anodizing, heat treating, and painting, even though we don’t do them in-house.”

The family-owned foundry enjoys a wealth of expertise, with industry veterans who’ve been with them for decades and long-term, trusted customer and supplier relationships with respected names like TriALco. “TriALco is one of our aluminum ingot suppliers,” says Cakora. “We’ve been buying from them for about 40 years. Our sand supplier, Warren Sand, has been with us from day one or close to it. Part of our culture is we want to be loyal to our suppliers. If we don’t have our suppliers, we can’t be in business.”

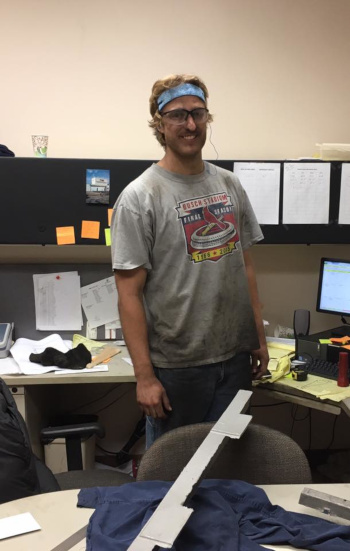

“We’re now fourth generation,” he continues. “My son, Ryan Cakora, he’s been here now five years and he’s our Plant Manager. With employees, we’ve been very fortunate to have a lot of good, long-term people. In this business, there’s no substitute for good experience.”

Tazewell doesn’t machine castings made by other foundries, but it does assist in casting design, at no extra charge. The foundry works in partnership with progressive pattern shops on all jobs that require new patterns, engineering changes, pattern rigging, or casting redesign. “We’re small, but we aren’t a garage-type operation,” Cakora explains. “At the size we are, we’re able to offer the personal touch. If customers need answers, they don’t have to go through layers of bureaucracy. We’re very responsive.” Tazewell also carries inventory for some of its larger OEM customers, helping them to shed the expenses and hassles of in-house inventory. “We’ve got flexibility there,” says Cakora. “We’re flexible whether it comes to service or quality. If quality issues come up, we’re able to jump on them quickly. Our management team, most of us wear several hats. We’re all in the loop with the big picture.”

Most of the company’s work is concentrated in the Midwest, but it does have customers headquartered in the South and on either coast. “We have a few jobs that we ship overseas,” says Cakora. “Although we do very little exporting ourselves, we’re global because our two largest customers happen to be big exporters. Our castings end up all over the world.” Tazewell relies primarily on freelance sales agents to bring them new customers. As a smaller manufacturer, it’s a better fit for them to outsource their sales force. “In this business, it takes a while to acquire a new customer,” says Cakora. “You might have to visit them several times before you get a chance to quote something, and that’s if an opportunity even comes up. It’s a process. The manufacturer representatives are a good way to go because we pay them if we get the business. We’re not covering payroll and expenses if we don’t.”

Plant Manager, Ryan Cakora

Lately, Tazewell has been striving to diversify its customer base in order to mitigate the risk of relying on larger, but fewer, customers as well as bring more stability to the revenues. “We’ve picked up a few new clients in the past year that are in some different markets we’re excited about,” shares Cakora. “This not only represents some additional work for us, but also some industries that are a little more recession-proof. Our two biggest customers operate in more cyclical industries, and you sort of ride the wave. When things go down, you go down with them. We’re optimistic about acquiring, not only new customers, but new markets, as well. We’re hopeful that in future downturns, we won’t be hit quite as hard.” While the company plans to vary its portfolio in response to changing economic conditions, it also intends to remain selective about the contracts it does accept. “We always make sure the work is a good fit for us. We don’t want to take something on that isn’t right, because that could end up being problematic down the road. We believe in controlled, cautious growth.”

The foundry industry and manufacturing in general, face many challenges, but one of the biggest is finding reliable labor – dedicated, dependable people who are safe and do good work can be hard to find and hold onto. Fortunately, this hasn’t been Cakora’s experience. He’s got 14 employees who have been with the company for over 20 years, seven that have been there more than 30 years, and three that have been with Tazewell for over 40 years. “Our problem isn’t finding skilled labor; it’s finding people that can come to work every day. If they can come to work, we can train them on the job. That’s what we’ve always done and will continue to do. In our machine shop, we’ve had some people that knew how to read blueprints or had taken a machining class at a vocational school. But basically, we trained them. When we find someone willing to show up to work, the chances are good they’ll become a long-term employee here, which is what we want.”

Cakora doesn’t have any expansion plans he’s ready to share, but the foundry’s South 2nd Street location leaves Tazewell with plenty of room to grow. “You need to decide who you are,” says Cakora. “We’ve done a few expansions over the years, but we’re on 30 acres of land so we’ve got the space to develop this operation if we need to. We like to have just one facility and one set of problems to deal with.”

AT A GLANCE

WHO: Tazewell Machine Works

WHAT: A manufacturer of complex machined aluminum sand castings

WHERE: Pekin, Illinois

WEBSITE: www.tazewellmachine.com

PREFERRED VENDORS

Warren Sand Co. – 217-414-1998

Aggregate Materials Broker

Established in 1917, Warren Sand is a fourth-generation company whose niche is providing quality Silica Sand and Filtration Media at the most competitive rates to our valued customers, while continuing to expand our customer base in a competitive environment. Our stress-free solutions are accomplished by negotiating with suppliers and transportation carriers on behalf of our customers.