Retech Systems LLC

A sound turnaround

Business View Magazine interviews Earl Good, President & Managing Director of Retech Systems LLC for our focus on Domestic Manufacturing in the United States.

Since 1963, Retech Systems LLC has been a global leader in the supply of metallurgical processing equipment and, today, is the world’s leading supplier of Electron Beam (EB) and Plasma (PAM) Cold Hearth furnaces for melting and refining titanium and titanium alloys. Retech’s advanced vacuum metallurgical systems also include Vacuum Arc Remelt (VAR), VAR Consumable (Skull) Casting, EB and PAM Consolidation furnaces, Plasma Welders, Vacuum Induction melting (VIM), Precision Investment Casting (DS/SC/EQ), Cold Wall Induction melting and casting, Vacuum Heat Treating, and Gas Atomization for metal powder production.

All Retech Systems furnaces are available in various sizes and configurations, from simple laboratory scale to large, custom-engineered systems. In addition, Retech provides customers access to a wide range of in-house resources, including technology, and material and process development. Identifying customer needs, as well as understanding the importance of producing relevant, viable, and cost-effective technologies, is the foundation upon which Retech is built.

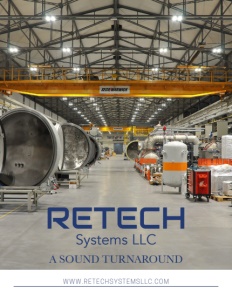

Assembly Hall Exterior Świebodzin, Poland

According to Company President and Managing Director, Earl Good, “We supply a lot of furnaces that provide products to the aerospace and medical industries – anywhere there’s a need for nickel or titanium or alloy materials to be melted down and made into other products. Our customers all buy somewhat similar furnaces, but they each have things they request or modify that make them unique as far as the special ingredients they use. They vary in size and output, and it’s all designed to make a certain part or provide a certain function within their process.”

Retech Systems is the most fully-integrated furnace manufacturer in the world, providing customers access to a wide range of in-house resources, including technology, material, and process development. In an effort to achieve the individual requirements of each project, Retech’s specialists work with each customer to tailor relevant, reliable, and cost-effective solutions. Experience and service, coupled with a complete portfolio of research, development, engineering, and manufacturing, are key elements behind the firm’s success and that of their customers. Whereas some competitors provide standard-type furnaces and others provide lower cost equipment, the advantage Retech brings to the table is providing large, customized furnaces that are specific to each customer’s application – tailoring offerings to customers’ needs. There is, indeed, an art to the metal melting process. Many customers choose to install the equipment on their own and Retech provides onsite supervision; other customers want Retech to do the installation. Either way, the company has a full after-market service department for ongoing customer support.

In 2011, Retech became a part of the SECO/ WARWICK group of companies. SECO/WARWICK is a technological leader in innovative, heat treatment furnaces. Its expertise includes end-to-end solutions in several categories: vacuum heat treatment; atmosphere and aluminum thermal processing; controlled atmosphere brazing of aluminum heat exchangers; and vacuum metallurgy. The SECO/WARWICK Group has 10 companies located on three continents with customers in nearly 70 countries, and production facilities in Poland, the United States, India, and China. In addition, the Group includes a number of service and sales offices in such countries as Germany, Russia, and France. The company provides standard or customized, state-of-the-art heat processing equipment and technologies to leading companies in the following industries: automotive, aerospace, electronics, tooling, medical, recycling, energy (including nuclear, wind, oil, gas, and solar), and the production of steel, titanium, and aluminum.

150kg Vacuum Induction Melting Furnace (VIM150kg-ED)

Last year, Retech Systems announced that much of the manufacturing and assembly work previously done in the company’s home office in Ukiah, California will be transferred to SECO/WARWICK’s facilities in Świebodzin, Poland, thus allowing it to be better-positioned to support both large capital projects, while also satisfying the regular, daily customer service needs that its clients demand and deserve. Currently, Good reports that Retech is also working on a long-term lease for a new office space and R&D facilities in the Buffalo, New York area.

“This is pretty exciting, because it’s a place that the City of Buffalo and the State of New York are investing into,” says Good. “They’re taking old industrial sites and refurbishing them into brand new facilities. So, we’re in the process of finalizing a ten-year lease that can be extended, which will help to bring together the engineers and equipment in the R&D facility, so some of our new hires in Buffalo will be able to work on some of the equipment. We expect to start moving in there in the March/April/May time frame. It depends on when we can gain access.”

“We’ve decreased the size of our manufacturing facility in Ukiah,” Good continues. “But we’ll continue to maintain the office out in Ukiah; there are a lot of good people there with technical knowhow and it’s important that we maintain that. We have increased the cooperation with the SECO Group, our owners, over in Poland; they have very good facilities, as far as manufacturing and assembly. We have a very skilled workforce over in Poland that we can utilize, but we also have options to go to other locations, and the Buffalo facility will provide options to do some manufacturing and assembly here in the U.S., as well. What we’re looking at doing is driving more global business, where we analyze each project opportunity and try to structure our offerings to give us the best chance to win. We are also focused on increasing the size of our aftermarket business on a global basis.”

Going forward, Good maintains that Retech Systems has a “very promising proposal backlog that will help us through the next couple of years. There’s a lot to be optimistic about,” he adds. “We continue to look for opportunities to create new technologies that the market wants and needs. Business has gone pretty well and we will have over $60 million in new capital equipment and combined after-market orders, this year. That’s exciting for us as we continue to turn the company around. We feel very good about the progress we’ve made over the last year-and-a-half, and what the future looks like.”

AT A GLANCE

Who: Retech Systems LLC

What: Custom melting furnace manufacturer

Where: Ukiah, California / Buffalo, New York

Website: www.retechsystemsllc.com

PREFERRED VENDORS

Weldall – www.weldallmfg.com

Weldall proudly supports our partner, Retech, by providing some of the most difficult large components needed for their overall systems to succeed. The quality and skill required to attain the “leak free” deep vacuum tight welding that is critical to these components is something that very few can build successfully. Like most of Weldall’s clients, they come to us when no one else can do it!

Weldall is a manufacturer of medium to large (up to 200 Tons) welded metal components, including machining and numerous additional secondary operations. For over four decades, Weldall has leveraged a unique set of skills and capabilities to continuously differentiate ourselves from the competition.

Weldall is capable of manufacturing prototype to production quantities of the highest quality and variety of parts and assemblies imaginable. These items can be made from a wide variety of alloys including, but not limited to: carbon steel, stainless steel, aluminum, monel, and manganese. Weldall can create weldments in excess of 400,000 pounds and successfully welds the heaviest requirements in the world.

We look forward to hearing about how we can help you with a weldment that “no one” (else) can do!

Solberg – www.solbergmfg.com

Founded in 1968 and headquartered in Itasca, Illinois, Solberg designs and manufactures filtration, separation, and silencing solutions for some of the most well-known companies in the world. A solution-focused, U.S.-based manufacturer with 20 facilities and offices throughout North America, Europe, Asia, South America, and Australia, Solberg supports customers ranging from original equipment manufacturers, to resellers, to end-users in industrial and scientific markets. Filtration expertise and highly diverse application experience uniquely position Solberg as a true partner, helping customers to innovate and discover new possibilities for their toughest filtration related challenges.

Solberg’s filtration and separation products protect equipment and help make industrial and laboratory working environments safer. Their extensive product line includes high-quality inlet vacuum filtration, liquid separation, and silencing products that protect a wide range of equipment including vacuum pumps, compressors, blowers, engines, fuel cells, and turbines.

Solberg approaches each application challenge with enthusiasm, creativity, and expertise. When more than a standard product is required to solve an issue, Solberg’s Design and Fabrication teams will collaborate to develop a configured or custom solution for its customers. The company can fabricate products in a variety of materials including carbon or stainless steel, and meet requirements including ASME, PED, and ATEX. For more information visit www.solbergmfg.com.