Integrity Products and Supplies

setting the industry standard

With cutting-edge CUI & SCC mitigation solutions.

Integrity Products has a very specific specialty as a corrosion mitigation solutions provider. The Alberta-based company creates, manufactures, and distributes world-class products for a variety of industries. Yet it is largely dedicated to actively researching and developing new and creative solutions that solve real industry problems with a particular focus on corrosion under insulation (CUI) mitigation.

In that realm, they collaborate with their clients in the oil and gas sector and offer technologies that are practicable and provide effective solutions to the challenges they encounter. Integrity Products can support the needs of many other industries including Petrochemical, Pulp and Paper, Power Generation, NDT and anywhere else insulated piping systems are exposed to the risks of CUI.

“Many of our products are driven by the need for maintenance on insulated piping systems” says Integrity Products and Supplies CEO Graham Brigham.

The company’s flagship product is the Integrity Plugz™ inspection port, which was created in 2011. These provide large, safe, and fast repeat access for monitoring and NDT testing of insulated assets. Integrity plugz are easy to install and highly visible, making them easy to locate at access points. They are provided in a package kit and do not require any special tools to install. Their design eliminates any sharp edges on the metal jacketing thus significantly reducing the potential for hand injuries. Best of all Integrity Plugz reduces the risk of CUI by maintaining a watertight, resealable, inspection point and allowing better NDT data collection.

This was Integrity’s first step into CUI mitigation and drove them to further investigate and develop products to help address this issue in the industry. So, in 2014 Integrity Products and Supplies Inc. was created to better describe their growing lines of CUI mitigation products.

In particular their PTFE Spacer Wrap is a new and innovative product that allows you to create a Non-Contact Insulation System. This ensures that wet insulation does not come into direct contact with the process pipe, substantially reducing the duration of wetness on the pipe surface while also acting as an impermeable barrier to leachates and other contaminants from the insulation material.

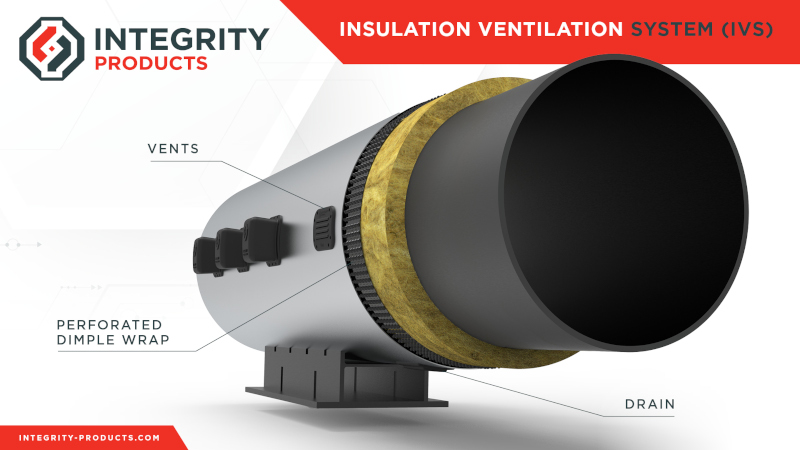

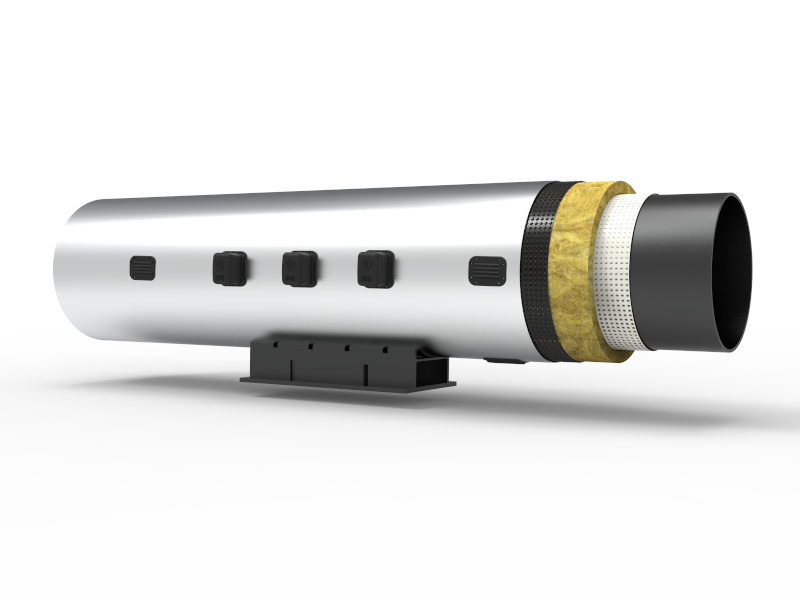

Integrity’s Insulation Ventilation System (IVS) is a 3-part system consisting of PVC Dimple Wrap, Vents, and Drains that work together to promote airflow along the insulation system. This limits moisture and condensation build-up in the insulation and can assist in drying out wet insulation, avoiding the need to dispose of and replace insulation material.

“We are able to significantly extend the life of existing insulation material while also ensuring that the insulation system is operating at peak performance,” says Integrity COO Karl Metcalfe.

This IVS system has also recently been recognized by the industry as it won the Materials Performance, Corrasion Innovation of the year award presented at the 2023 AMPP conference in Denver, Colorado.

Integrity is also currently conducting a carbon reduction study designed to show that not only does their IVS system deliver significant cost savings but also significant carbon savings! Working in collaboration with a 3rd party carbon consultant and one of their largest clients, Integrity products aim to show that the use of their products is also the right choice from an environmental aspect, helping the environment and helping their clients reach their carbon reduction targets. The results of this study will be made public at https://www.integrity-products.com and through their social media platforms in the coming months.

Integrity is also currently conducting a carbon reduction study designed to show that not only does their IVS system deliver significant cost savings but also significant carbon savings! Working in collaboration with a 3rd party carbon consultant and one of their largest clients, Integrity products aim to show that the use of their products is also the right choice from an environmental aspect, helping the environment and helping their clients reach their carbon reduction targets. The results of this study will be made public at https://www.integrity-products.com and through their social media platforms in the coming months.

According to Mr. Brigham, the company pays close attention to new technologies that can effectively solve insulated piping issues in the future. For that reason, Integrity also invests in research and development and can serve not just as a solutions provider but as a trusted consultant. Even with less than 10 full-time employees, Integrity has the capability to move a product idea from the concept, design, testing phase through to a finished product in a relatively short space of time due to their in house design and 3D printing abilities.

“We can design new products when needed and are here to work closely with our clients,” he says.

One of the reasons that Integrity has been so successful, growing sales to eight figures, even through the Covid pandemic, is that it works closely with Asset Owners, Contractors and its Distribution Partners. This emphasis on working closely with distribution partners to support sales allows Integrity to remain “lean and focused on its core competencies” according to Mr. Metcalfe, without the need for additional warehousing, inventories and supporting staff.

However, the company is looking to further grow in the Canadian & US markets specifically by increasing sales in the U.S. as Mr. Brigham feels that the U.S. market offers significant potential for growth in multiple industries, calling it a major goal in 2023.

“We’ve had great success with our existing sales team but we know finding the right people will be hard,” Mr. Metcalfe says. Mr. Brigham agrees, adding that while the products Integrity manufactures and offers to distributors may be simplistic in nature, they function as a highly technical application.

As CEO, Mr Brigham spends much of his time on product development and design while also finding the most efficient manufacturing processes available. Recently that has included handling about 80 percent of the manufacturing in China, which is cost effective and increases production capacity. Supply chain issues have plagued manufacturers since the start of the Covid pandemic and also now with the current geopolitical tensions but one of the reasons for the manufacturing in China is that most of the raw materials already come from here regardless of where final manufacturing takes place.

Created using Luxion Technology (luxion.com)

“It doesn’t really matter where the products are made as long as they have the highest level of quality and meet our (demanding) standards,” Mr. Brigham says.

While Covid did cause a short-term slowdown in business, the second half of 2020 was an extremely busy and financially successful one for the company. One of the biggest reasons for that was the positive and transparent relationship that Integrity’s team has with its customers. As business began to slowly open back up, Integrity worked very closely with key customers to forecast demand for its products which allowed them to manage extended manufacturing lead times and inventory levels.

While Integrity’s focus is on mitigating corrosion, it leans on its core values to ensure that such goals are attainable. It should come as no surprise that one of Integrity’s pillars is just that – integrity. According to Mr. Metcalfe, this is defined as “doing the right thing even when no one is looking.”

Another pillar of success is continuous improvement, which is recognized by the drive to develop and learn. If there is a more cost-effective and successful solution, Integrity wants to utilize this to ultimately deliver better service and experience to its customers.

Third is the concept of teamwork. This extends not just to employees but also customers, distributors, installers, business partners, and vendors. Integrity Marketing Director Vanessa Sjogren admits that there are many such partners and vendors that the company relies on to support product awareness and supply. There are in fact, “too many to name, lest we leave one out,” she says.

Together these core values are designed to remind Integrity of where it came from more than a decade ago. Says Mr. Brigham, “we don’t want to become a business that forgets about our core values. Even as we grow into revenues that are in the tens of millions, we will always treat all customers as if their request is the most pressing emergency for us – no matter how big or small the request is.”

Integrity continues to position itself as a premier solutions provider in the industry that works directly with asset owners, engineering firms, industrial contractors, and related parties. There is a real demand for its products and collective knowledge.

Aging infrastructure has brought CUI to the forefront, with costs surrounding CUI-related problems estimated to be in the billions of dollars each year. Implementing systems that allow for early detection, access for inspection, ongoing monitoring, moisture mitigation, and safeguards to isolate problem areas can help reduce these costs.

Integrity hit its sales targets in the last three years, achieving 50 percent growth year-over-year. In addition to expanding sales in the U.S., Integrity plans to utilize successful online marketing and social media marketing tactics overseen by Mrs. Sjogren to further grow sales while emphasizing the role of new product development, such as its PVC Dimple Wrap, insulation ventilation system.

Mr. Brigham says Integrity holds 16 current patents, nearly half of which were created since the start of the Covid pandemic. “Innovation is and always will be at the core of what we do,” he says.

AT A GLANCE

Integrity Products and Supplies

What: Leading products and technology solution provider in the Oil & Gas industry

Where: Sherwood Park, Alberta, Canada

Website: https://www.integrity-products.com/

PREFERRED VENDORS

Amity Insulation Group Inc. – www.amityinsulation.com

Amity Insulation is pleased to represent Integrity Products and we are proud to be working with such a wonderful group of people. Distributing the Integrity line is an honour and fits nicely with our niche of providing high quality products to the industrial sector.

Congratulations on your well deserved 2023 CORROSION INNOVATION OF THE YEAR AWARD.