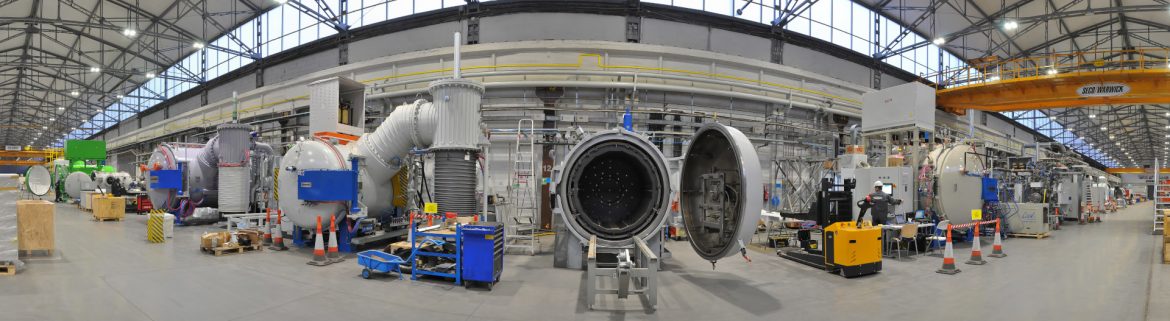

The Seco/Warwick Group – North America

Providing furnace solutions

Business View Magazine interviews Keith Boeckenhauer, President and Managing Director of the North American subsidiary of the Seco/Warwick Group.

The Seco/Warwick Group is comprised of nine companies on three continents that provide standard and customized heat processing equipment for its customers in over 70 countries in the following industries: automotive, aerospace, tools & dies, medical, recycling, energy – including nuclear, wind, oil, gas, and solar – and the production of steel, titanium, and aluminum. As a creator of over 4000 solutions, Seco/Warwick can be called an innovative heat treatment leader – the controlled heating and cooling of metals to alter their physical and mechanical properties without changing the product shape – with expertise in five categories: vacuum heat treatment, atmosphere and aluminum thermal processing, controlled atmosphere brazing of aluminum heat exchangers, and vacuum metallurgy.

“Seco/Warwick was formed in 1984,” recounts President and Managing Director of the North American subsidiary, Keith Boeckenhauer. “We started making aluminum process furnaces, aluminum melting furnaces, steel heat treating furnaces with protective atmosphere, and vacuum furnaces for heat treating of the higher technology materials. Then, in the mid to late ‘80s, we developed a design for brazing of primarily automotive aluminum heat exchangers, which we call CAB – controlled atmosphere brazing.

“In 1991, we joint ventured with a company in Poland and formed Seco/Warwick Ltd. as a sister company to serve Eastern Europe and Russia. In 2002, we bought one of our competitors, Camlaw Ltd., that was going out of business, and that added to our dominance in the heat exchanger brazing field. Right now, as a Group, we have branches in the U.S., Poland, Germany, Russia, India, and China. We employ, globally, roughly, 850 people. In 2007, the company went public on the Warsaw stock exchange, so at that time the Polish facility became the headquarters of the Group.”

Continuous Homogenizing

“Many people don’t realize that a furnace is similar to an automobile,” Boeckenhauer remarks. “There are different parts that have to go together, and work together, to get the right result out the back end. So, we view ourselves, basically, as systems integrators – we design the furnaces, we write the control programs, and we’re integrating other components into one piece of equipment that can do a process. So, we have heating source vendors, vendors for combustion equipment, burners, heating elements, insulation, controls, and insulation that all have to be integrated within the furnace as a package.”

Boeckenhauer says that Seco/Warwick is able to maintain its competitive edge because of its proprietary and innovative technologies. “In the aluminum industry, for example, we’ve got a furnace that uses a jet speed air flow to heat the load faster than the traditional mass flow,” he explains. “A typical mass flow furnace needs a large mass of heated air to heat-treat the aluminum load. The jet vortex design uses high speed air, which impinges on the aluminum that you’re trying to heat-treat. So, it transfers heat much faster than just moving a large mass of air. We have that in our aluminum process furnaces for aluminum coils, making product for use in the automotive industry, the packaging industry, and the building products industry. ‘Vortex’ is the trademark of our high speed coil annealing furnaces.”

“We employ the same theory of jet speed impingement on what we call ‘logs,’ which are turned into billets for extrusion,” Boeckenhauer continues. “The logs are round bars of aluminum that can be 6, 8, 10, 12, 14, 16, or 18 inches in diameter and upwards of 18-20 feet long. We have a design that uses the jet velocity air impinging on the logs, heating them much quicker than what was done 15 or 20 years ago. Those logs are then used in aerospace, automotive, building materials, packaging, etc. We also have a trade name for our drop bottom furnaces, called ‘VertiQuench’, used primarily for aerospace applications, but can also be used for automotive parts. This is a furnace that takes the load upwards of eight feet in the air, depending on the load size and then, when the heating cycle and the processing cycle is done, it drops those parts into a quench bath, typically water, very quickly, to freeze the alloy components in the correct metallurgical matrix for the part. While these are technologies that others supply, the way we circulate the air and how the air hits the load is unique to us.”

Vertical Tower Furnace

Another product group manufactures equipment for the heat treatment of aluminum and controlled atmosphere brazing (CAB). As shown by Seco/Warwick in numerous installations around the world, technical experience and an innovative approach make the CAB solution the preferred joining technology for battery cooling plates within the hybrid electric vehicle (HEV) and electric vehicles (EV) market. The automotive market, which currently is both very vibrant and demanding, provides for 30 percent of Seco/Warwick customers.

The idea that the future belongs to electric vehicles is a hot topic, nowadays. The question is not whether, but when, e-mobility will spread globally and what it means for automotive component manufacturers. The views on this matter are divided. According to the forecasts by the International Energy Agency, in 2030, only 40 percent of vehicles around the world will be driven by a combustion engine, and the majority of the market will be consumed by hybrid and electric vehicles. Other, more skeptical automotive market analysts believe that in 2050, only 25 percent of cars sold worldwide will be electric. According to Bloomberg and ING, in 2020 the difference in price between electric and conventional vehicles will fade, which will favor conventional cars being displaced from the market by electric vehicles thanks to lower operating costs of the latter. EVs have the potential to disrupt the automotive market while paving the way for increased energy security and eco-friendly, low-emission future.

Boeckenhauer notes that, for now, the Group has no further plans to expand its geographical footprint. “At this point in time, we’re pretty well set as far as expansion goes. But, because we are in the U.S., we need to emphasize that this market had the largest share in the sales of the Seco/Warwick Group and accounted for 38 percent of the Group’s total sales. At the same time, sales in the U.S. market increased by 29 percent in 2018, compared to 2017.

For decades, Seco/Warwick has played a fundamental role in the evolution of technologies, providing its customers with the finest system value and professional technical services, keeping equipment online, and operating efficiently. The Group has won many awards over the years for innovation in furnace design and operation, as well as a growing number of patents. “We’ve been in business for many, many years, and as far as processes go, we’ve pretty much seen everything,” Boeckenhauer says, in conclusion. “60 percent of our employees are engineers, so we have the engineering background to customize any furnace design that we have world-wide, and we can customize equipment to do the specific things that a customer wants.”

AT A GLANCE

WHO: The Seco/Warwick Group

WHAT: A manufacturer of heat processing equipment

WHERE: Headquarters in Warsaw, Poland

WEBSITE: www.secowarwick.com

PREFERRED VENDORS

Industrial Gas Engineering Co., Inc. – www.igefans.com

IGE has served the heat treating industry since 1924. Our products are manufactured in the U.S. and shipped worldwide. We are widely recognized as the leader in the high temperature fan industry and specialize in custom fans. We also offer direct drive water-cooled sealed motors which allows for gas tight fan assemblies for use in vacuum furnaces. Our spare parts and repair departments have some of the fastest turnaround times in the industry, try us!