Maxxon Corporation

The floor specialists

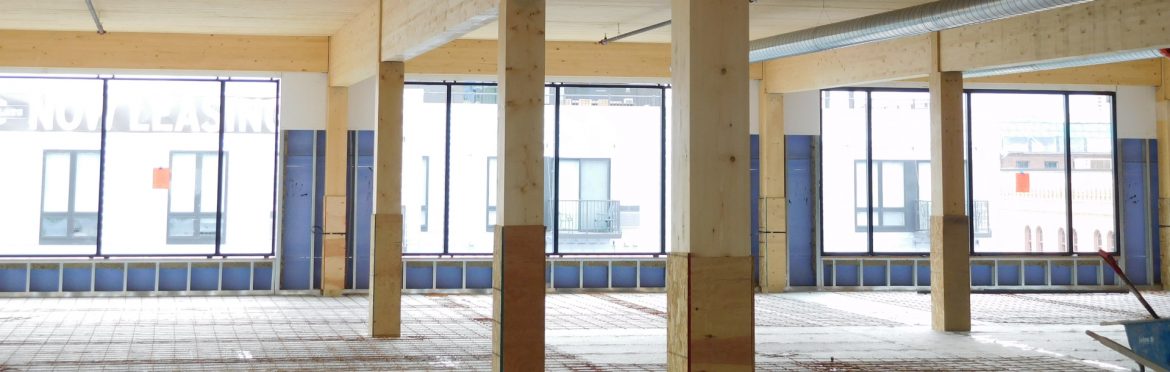

Around the world, designers are increasingly leveraging the strength, stability, and design flexibility of mass timber products, such as cross-laminated timber (CLT), to push beyond wood’s perceived boundaries, achieving building heights and spans that would have once required concrete, steel, or masonry for structural support. Mass timber construction is a category of framing styles, typically characterized by the use of large, solid, pre-engineered wood panels for wall, floor, and roof construction. Adoption of mass timber is on the rise, largely due to its aesthetic appeal. Developers are leveraging the natural beauty of wood to enhance occupant comfort by exposing the ceiling side of the floor/ceiling assembly (the build-up that includes the ceiling, the structural floor component and any additional materials on top of the structural element). This presents unique challenges for fire and sound control and has led many developers and architects to seek construction expertise from Maxxon Corporation, makers of sound and fire code compliant subfloor systems.

Maxxon Corporation is best known for starting the gypsum underlayment industry in 1972 with Gyp-Crete®, a mixture of gypsum and Portland cements, water, and sand that is commonly used in new wood frame construction for its fire resistance and sound dampening properties. In the 1990’s, Maxxon again led the industry with the introduction of Acousti-Mat®, a line of sound control mats designed for installation below gypsum underlayments, like Gyp-Crete. Used together, these products form a permanent sound control system that reduces both airborne and impact sounds transferred through the floor. These systems are used readily in wood frame, multifamily construction to achieve fire and sound code compliance.

“Mass timber came to the United States in 2012, and every year since, it has continued to grow,” says Beth Lee, Maxxon’s Senior Development & Project Manager. “Maxxon became aware of it in 2016 when a customer contacted us, asking for guidance on fire and sound performance on a mass timber project. We recognized this as an emerging construction trend that fit into our wheelhouse and decided to learn more.”

Continual research, an important priority at Maxxon, is under the purview of Erik Holmgreen, the company’s VP of Research & Development. “An important part of what my group is trying to do is to expand off our 50-year history of experienced applicators. We want to be looking for new products that complement what they do.” Maxxon Corporation uses feedback from their applicator network and industry partnerships to inform what the market is looking for and what trends are growing.

In the mass timber space, Maxxon first partnered with SmartLam, a manufacturer of cross-laminated timber, to exchange a basic understanding of mass timber construction and sound control in buildings. That led to the first round of sound testing and every year since then Maxxon has invested in testing to better understand and predict how sound behaves in mass timber structures. In 2018, the International Building Code adopted several code changes specifically addressing the use of mass timber to build above 85’ high. For very tall mass timber buildings, fire code is achieved through full gypsum encapsulation, i.e. drywall on walls and ceilings and gypsum underlayments on the floor. In 2019, Maxxon teamed up with Woodworks, a non-profit that promotes the use of wood in construction, and Worthington Armstrong Venture (WAVE), a leading manufacturer of suspended ceiling systems, to design code compliant floor/ceiling assemblies.

Rendering

The most recent test program was informed by and developed around commonly requested design objectives including price, performance, speed and the ability to showcase an exposed ceiling. Maxxon and WAVE were able to design floor ceiling assemblies to meet these goals. The testing program generated a substantial amount of data, lending to a high degree of confidence in the performance of each assembly. The volume of data provided an additional outcome – the ability to assess how each component contributes to the assembly’s acoustical performance. “While this type of data exists for other common types of construction, mass timber is still in early adoption, so this data has not existed before now,” says Holmgreen.

Innovation is at the core of what Maxxon was founded on. In the late 1960s, two brothers, Ron and Clyde Jorgenson, who were running a drywall business, saw an opportunity in the flooring side of the construction trade. “They were drywallers often working on top of lightweight concrete floors. They observed many issues with cracking and creating level floors”, recounts Josh Jonsson, Executive Vice President of Maxxon Corporation located in Minnesota. Gypsum is a naturally occurring mineral, most commonly known as the main component of drywall. “They had the thought of trying to flatten the floors with the gypsum that they were using on walls and ceilings.” This led to the invention of Gyp-Crete.

From the original Gyp-Crete floor underlayment, the Maxxon line has expanded to include five gypsum underlayments, two self-leveling underlayments, seven encapsulated sound control mats, one topical sound mat, and solutions for moisture mitigation and lightweight deep-fill applications. Jonsson says that Maxxon Corporation defines itself by having created a niche in the concrete industry and he indicated that the company would continue to stay ahead of the competition through its ability to identify and capitalize on underrepresented opportunities in the markets they serve. This past November, the company began a pilot launch of a brand-new product line called Renovation by Maxxon.

“Over time Gyp-Crete, like anything else, ages and needs to be repaired,” explains Lee. “A lot of the calls that come into our office are asking how to repair or replace gypsum underlayment. We took a look at the renovation market, and realized that it is significantly larger and less cyclical than the new construction market. As we were evaluating what a product line might look like, we realized that the product offering for multifamily floor renovations was quite limited. Our current focus with Renovation by Maxxon® is on multifamily renovation products that offer code compliance and gypsum compatibility.”

“We want to grow into new areas that would still fit the model of identifying unique solutions to problems that nobody else is handling in the right way,” Jonsson states. “We don’t want to become a commoditized product. We don’t want this sitting in every big box store. We want to continue to be a unique fit for the construction industry.” At nearly 50 years in existence, Maxxon is accelerating into this vision. In 2020, Maxxon eagerly anticipates the launch of several new products as well as the investigation of new business opportunities informed by emerging trends in the market.

AT A GLANCE

WHO: Maxxon Corporation

WHAT: Specialist in flooring underlayment products

WHERE: Hamel, MN

WEBSITE: www.maxxon.com

PREFERRED VENDORS

AUS Decking – ausdecking.com

From sound attenuation mats in new construction to floor leveling in the renovation market, AUS has stayed on the forefront of emerging technology through our symbiotic relationship with Maxxon. We have enjoyed this partnership for nearly 40 years, and we look forward to the next 40!