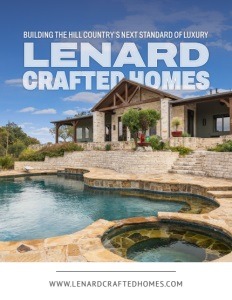

Building the Hill Country’s Next Standard of Luxury

Constructed on High-Performance Workmanship, Healthy-Home Science, and a Concierge-Level Client Experience

In the Texas Hill Country, luxury homebuilding has never been just about square footage or finishes. It’s about place, permanence, and the promise of a sanctuary designed to last. For Lenard Crafted Homes, that promise carries a deeper meaning—one grounded in high-performance construction, healthier indoor environments, and a client experience intentionally designed to feel less like a project and more like a partnership.

Owner Craig Lenard defines his company’s differentiators through three guiding pillars. The first is the most distinctive: Lenard Crafted Homes builds healthy, high-performance homes tailored to client needs and sensitivities, with a deliberate focus on preventing future issues such as mold and microbial growth. The second is a world-class building experience—one Lenard compares to “checking into the Ritz-Carlton versus the Motel 8.” The third is values-based leadership. “We’re Kingdom-owned,” Lenard says, emphasizing the company’s belief that the business is managed with stewardship, integrity, and accountability.

While all three pillars shape how the company operates, it’s the healthy-home focus that is increasingly resonating in the market—especially among clients who have lived through the hidden costs of standard building practices.

A Builder’s Full-Circle Path

Lenard’s approach is rooted in both personal experience and professional evolution. He grew up in the homebuilding world; his father started the family business in 1980, and Lenard spent his teenage years learning construction on job sites. After high school, he took a different path, earning an education degree from Tarleton State University and spending roughly a decade as an agriculture teacher. He taught ag science and technology, construction trades, welding, and animal science—skills that, in hindsight, became part of the foundation for how he trains and leads teams today.

Eventually, he felt drawn back into the family business. When his mother became seriously ill and his parents were largely away from day-to-day operations for an extended period, the responsibility of carrying the company forward fell to Lenard. With a strengthened sense of purpose and a growing team around him, he stepped into leadership—and the company continued to grow.

What a Building Biologist Brings to Homebuilding

Lenard’s story took another critical turn when his family faced a health crisis that changed how he viewed construction forever. In the home he and his wife purchased early in their marriage—one they did not build—hidden mold exposure slowly took hold. There were no obvious wall stains or visible surface growth. Yet symptoms escalated over time: his wife

became increasingly ill, Lenard began noticing his own symptoms, and their daughter struggled with learning in ways that didn’t add up. Toxin testing ultimately revealed elevated mold exposure, and investigation identified mold in concealed areas throughout the structure.

Rather than attempting extensive remediation with uncertain outcomes, the family made a difficult but decisive choice: they tore the home down and rebuilt. That experience became the catalyst for Lenard’s training in building biology, a discipline he describes as the study of how the built environment impacts human health and the natural environment.

A building biologist, Lenard explains, evaluates materials, assemblies, and design practices through a health and performance lens—reducing toxic load, minimizing moisture risk, and building in a way that helps occupants thrive. It also supports broader sustainability goals, including reducing unnecessary material transport and choosing approaches better suited to the local climate and natural environment.

For Lenard, the most unsettling realization was that the conditions that led to mold growth weren’t the result of extreme negligence. They were the product of common building methods—standard practices that did not sufficiently protect against long-term moisture and microbial risk. Once that became clear, he began applying healthier, more durable principles across projects already in progress, shifting his company toward a new standard of performance.

A Luxury Builder by Design—and by Discipline

Lenard Crafted Homes builds fully custom homes and has never built the same home twice. Its annual volume—typically five to seven homes, ranging roughly from $1.5 million to $6 million—reflects intentional capacity control rather than demand constraints. Lenard notes that while the company has always built luxury custom homes, the last several years have been marked by significant internal growth: refining systems, improving processes, investing in people, and strengthening delivery.

The company operates in what Lenard describes as a “scale season,” applying what was built internally to grow responsibly—without losing precision or experience quality. Project managers are intentionally capped at one to two projects at a time, depending on complexity, because the homes are highly detailed and require constant decision-making, communication, and oversight.

From Vision Meeting to Fixed-Cost Clarity

Lenard Crafted Homes places the client relationship at the center of its process—and that relationship begins before a plan is drawn. The first step is a “vision appointment,” ideally held on the client’s property. The purpose is simple but powerful: walk the land together, identify orientation, talk about sunlight and views, and begin shaping a shared dream. Just as important, it’s a two-way fit assessment. Lenard is candid that not every client is a match, and the company will decline work where the relationship foundation doesn’t feel aligned.

From there, clients meet in the company’s office for a pre-construction discussion that outlines next steps and expectations. Lenard Crafted Homes partners closely with a small group of

architecture and design firms and attends early design meetings to ensure scope and cost remain aligned from the start.

Before plans progress too far, the company develops a preliminary budget designed to keep the project within a tight range. The intent is to prevent clients from investing heavily in design development only to discover the home is outside their financial comfort zone. Once plans are finalized, the company moves into a fixed-cost building contract, taking roughly three weeks to produce a full estimate. If adjustments are needed, the team works through options collaboratively—recognizing that in custom building, clients aren’t selecting from three appliance packages; they’re selecting from the entire marketplace.

Technology That Supports Transparency

To maintain clarity throughout a complex, high-touch build, Lenard Crafted Homes uses Buildertrend as its core client portal and project management platform. Change orders, invoicing, selection approvals, photo documentation, scheduling updates, and payment tracking are centralized in one system, allowing clients to stay informed regardless of location. Weekly schedule updates and daily photo progress help reduce uncertainty and support proactive decisions—an approach that reinforces trust while keeping timelines realistic.

A Relationship Model Designed for Referrals

Lenard’s view on the construction experience is straightforward: custom homebuilding is not transactional. It is relational, long-term, and deeply personal. The company designs its communication and project rhythm so thoroughly that clients rarely need to “chase” answers; they receive information before they ask.

One signature tradition underscores that commitment. After clients settle into their new home, Lenard Crafted Homes arranges a private chef experience: a multi-course, wine-paired dinner hosted in the home for a small group of the client’s closest friends. The company does not attend, keeping the moment personal and relaxed. The goal is to let clients enjoy their home in a meaningful way while naturally sharing their experience—an elegant capstone that turns satisfaction into storytelling.

Investing in the Company: Facilities, Systems, and People

Lenard Crafted Homes is investing heavily in internal capability. The company recently expanded and upgraded its office environment, creating a stronger base for team operations and client meetings. More strategically, it is investing in human capital—developing project managers through a structured training model.

Lenard has found that hiring highly relational people with baseline construction understanding and then training them in the company’s systems and standards produces stronger results than hiring someone who is steeped in standard practices that don’t align with the firm’s high-performance approach.

These apprentices spend roughly 12 months in a learning phase before taking on full responsibility—an investment Lenard sees as essential, with strong returns once a project manager begins running jobs under the company’s model.

On the business development side, the company has also strengthened its marketing function. With Payton Schuette now serving as Marketing Director, Lenard Crafted Homes is formalizing its message and expanding its visibility—particularly around the healthy-home differentiator and its client experience philosophy.

Adapting to Economic Realities Without Losing Quality

Like every builder, Lenard Crafted Homes has felt the impact of interest rates, labor availability, and material cost shifts. The company has responded by building more control into its delivery model. Lenard has created vertical alignment through related service companies, including insulation and painting, allowing more consistency where quality and pricing volatility can otherwise disrupt schedules. The firm also maintains strong relationships with long-tenured trade partners—many of whom have worked with the company for decades.

Lenard credits one additional practice with sustaining loyalty: trades are paid reliably and on time, regardless of client payment timing. In his view, that consistency earns trust that protects schedules and workmanship—particularly in a tight labor market.

At the client level, Lenard notes that the firm’s typical customer profile creates some insulation from economic shocks. Many clients are nearing retirement or have retired and are building a long-planned home. Rather than stopping projects outright, rising rates may change timing and draw strategy. With cash earning more in higher-rate environments, clients often prefer to keep funds working until needed. Lenard Crafted Homes supports that by planning draw schedules with clarity and lead time, aligning construction cashflow with client financial strategy.

Crafting the Hill Country Aesthetic

Design-wise, Lenard Crafted Homes builds across styles, but there are clear themes that repeat because they match the Hill Country’s character. Timber and stone feature prominently, often within timber-frame structures crafted in partnership with Timberlyne, a national timber-frame company for which Lenard Crafted Homes serves as a preferred builder. The result is a distinctive blend of ranch, European influences, and modern Hill Country forms—sometimes incorporating contemporary rooflines while maintaining a grounded, natural-material palette.

Community Resilience and Rebuilding After Catastrophe

Operating in the Hill Country also means living close to nature’s volatility. Lenard described the region’s recovery from devastating flooding as both sobering and inspiring—revealing the best of community response while also attracting opportunists attempting to take advantage of homeowners in crisis.

From a building biology lens, Lenard understood immediately what water intrusion could trigger. In many cases, the long-term risk isn’t just damage—it’s mold. As soon as access was possible,

Lenard Crafted Homes mobilized to help homeowners with rapid interior demolition and removal of waterlogged materials, doing what could be done quickly to preserve structures and reduce microbial growth risk.

The experience reinforced a theme that runs through the company’s identity: homes are meant to be sanctuaries. Protecting that sanctuary requires both science and urgency when disaster strikes.

Looking Ahead: Expanding Impact Without Losing Intent

Over the next 18 to 24 months, Lenard Crafted Homes plans to continue building awareness around healthy, high-performance construction while scaling thoughtfully. The near-term goal is to comfortably deliver eight to ten luxury custom homes annually with the existing team—without sacrificing the hands-on project management, transparency, and concierge-level client experience that define the brand.

Lenard is equally committed to being a resource to the broader building community. While he is not seeking to formalize training programs, he is clear that any builder who wants to learn healthier building principles will receive his time and insight—because for him, this is not a trend. It is an evolution that the industry cannot afford to ignore.

In a crowded luxury market, Lenard Crafted Homes stands apart by offering something deeper than craftsmanship alone: homes designed not only to impress, but to protect, perform, and sustain the people living within them.

AT A GLANCE

Who: Lenard Crafted Homes

What: Leading luxury homebuilder with local expertise and high performance craftsmanship in all its builds

Where: Hill Country, Texas

Website: www.lenardcraftedhomes.com

PREFERRED VENDORS/PARTNERS

Trade-Mark Air Conditioning: www.trademarkairconditioning.com

For over 35 years, Trade-Mark Air Conditioning has delivered trusted comfort across Ingram and Kerr County. As a Carrier Factory Authorized Dealer, they provide energy-efficient HVAC repairs, replacements, and indoor air quality solutions, backed by 24/7 emergency service, expert technicians, and a steadfast commitment to customer care for Texas Hill County homeowners.