The American Foundry Society (AFS)

Supporting the metalcasting industry

Business View Magazine interviews Doug Kurkul, CEO of the American Foundry Society (AFS), for our focus on the Metalcasting Industry

The American Foundry Society serves the metalcasting industry and its supply chain. Based in Schaumburg, Illinois, AFS is comprised of both corporate and individual members throughout North America and beyond. The corporate membership is a mix of foundries, suppliers to the metalcasting industry, and OEMs that purchase and use castings.

Business View spoke with Doug Kurkul, who has been the organization’s CEO since January 2016, for his insights into AFS and the future of the industry.

BVM: Thank you for joining us for this interview, Doug. To begin, how would you describe the metalcasting industry?

Doug: Thank you for the opportunity. Metalcasting is a $44 billion industry that accounts directly and indirectly for about 490,000 American jobs. The metalcasting industry provides exceptionally rewarding careers for those with the right skills and dedication. It’s a modern industry that combines ancient roots with advanced technology and is the centerpiece of today’s manufacturing economy. That’s important because manufacturing, in turn, is essential for a prosperous society with high living standards and a growing economy.

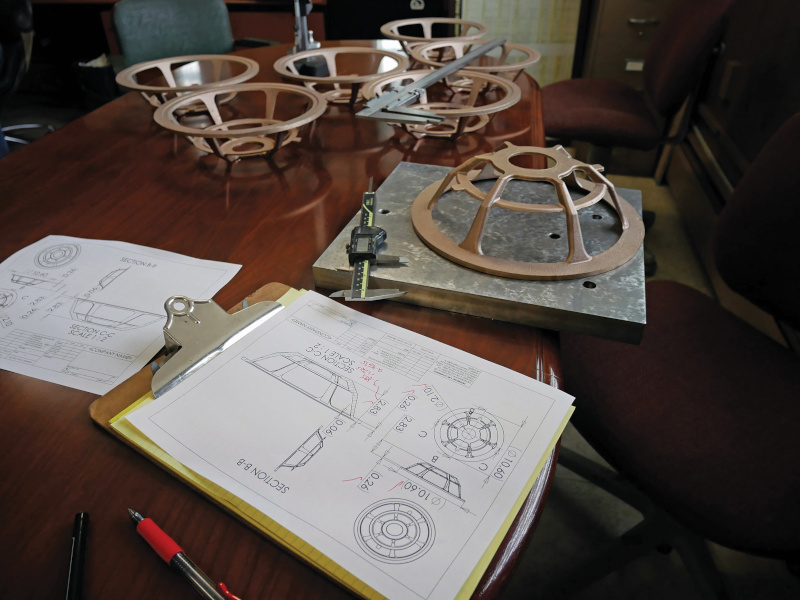

There are approximately 1,745 foundries in the United States. There are also robust foundry industries in Canada and Mexico, as well. These foundries produce highly engineered products called castings, made from a variety of molten metals, including iron, steel, aluminum, copper, brass, bronze, titanium and other metals. Only China and India produce more castings than the U.S. Making high-quality castings is a complex process that requires excellent designs and careful attention to quality and chemistry. Recycling is an integral part of the industry. Since metalcasting is an essential industry, U.S. foundries operated – safely, in compliance with government policies – throughout the pandemic.

Nearly everywhere we go, castings are omnipresent and indispensable. That includes motor vehicles; agricultural, mining and construction equipment; water lines that transport clean water and wastewater to and from our homes and schools; energy development; aerospace and national defense; medical devices; and even that cast iron cookware in your kitchen. One way to think of it is that we are seldom more than 10 feet from a casting.

BVM: Congratulations on the 125 anniversary of AFS this year, can you give us some details on the Society?

Doug: AFS is a dynamic association with an educational arm, 39 regional chapters, 41 student chapters, 13 technical and management divisions, a Future Leaders (young professionals) group, a Women in Metalcasting group, and about 1,000 volunteers.

Multi-faceted in nature, AFS is a technical society, an advocacy organization, an education provider, a trade show producer, as well as a publisher. Our mission is to advance the success of our members and the industry through advocacy, education, and innovation. Our vision is to be recognized worldwide by industry stakeholders as the leading voice and resource on technical, management, and advocacy priorities pertaining to metalcasting. AFS was founded in 1896, and we have been commemorating the 125th anniversary in a variety of ways throughout 2021.

BVM: How is the organization governed?

Doug: AFS is member-led and staff-administered. We have a 20-member Board of Directors and each Board member serves a four-year term. Our elected officers are Mike Lenahan (KB Foundry Services); Adam San Solo (U.S. Foundry); Brad Muller (Charlotte Pipe & Foundry); and Peter Reich (LaempeReich). Reporting to the Board of Directors are the Technical Council, the Management Council, and the Research Board. The organization’s CEO reports to the Board; the balance of the staff reports, in turn, to the CEO. Our key documents are our By-Laws; the Board of Awards Manual which outlines the process for selecting the international awards that we present every year; a Committee Manual; and the Code of Conduct, with which all members and staff must comply.

An effective association starts with sound governance. Beginning with our 2015-2016 AFS President Bruce Dienst (Simpson Technologies), and the presidents that followed, AFS has gone to great lengths to modernize its governance and develop an effective, multi-year strategic plan.

BVM: What trends are you seeing in AFS membership?

Doug: The first thing we would emphasize is that the AFS membership is comprised of an amazing group of people. They are committed to the quality of castings, to innovation, to meeting customer needs, to the future sustainability of the industry, to the health and safety of their workforces, as well as to one another through the sharing of best practices. You don’t see that in every industry.

Corporate membership has grown from 794 five years ago to 938 today. We attribute that growth to three factors. The first is the quantifiable value that AFS provides, in terms of business leads generation, statistical reports and forecasts, new programs, as well as other benefits exclusively to corporate members. The second factor is the superior member service provided by our responsive and knowledgeable 30-person staff. The third factor is the desire of corporate members to support the vital mission of advocacy, education and innovation. They want to have a seat at the table and be a part of leading our great industry forward alongside industry peers and they enjoy doing so.

AFS also has about 6,000 individual, student and retiree members options with more limited benefits. There really is a place for everyone at AFS.

BVM: What types of events does AFS present?

Doug: AFS holds technical and management conferences throughout each year in various locations. For example, we held our first Foundry Industry 4.0 Conference virtually in June 2021, and plan to present the next one in person near Chicago in July 2022. AFS will be hosting a major Environment, Health and Safety Conference in Birmingham in October 2021, a management summit in Schaumburg in May 2022, an Aluminum Casting Conference in St. Louis in June 2022, and a Sand Conference in Milwaukee in September 2022.

AFS presents a massive trade show and congress every three years, and smaller ones the other two years. The large shows, known as CastExpo, draw attendees from around the world to see innovative equipment, new technologies, and robotics operating live on the show floor, making it North America’s largest metalcasting event. CastExpo 2022 will be held in Columbus, Ohio, April 23-26, 2022. It will attract more than 6,000 people from across the industry and there will be dozens of technical, management and educational sessions. The excitement is already building for the show. Your readers can learn more at www.CastExpo.com .

BVM: How does AFS advocate for metalcasters in the nation’s capital?

Doug: AFS is engaged in advocacy because the decisions being made in Washington have enormous implications for metalcasters. Policymakers can’t be expected to be experts on every topic and industry. AFS’s role is to communicate the importance of metalcasting, to explain the implications of pending proposals, and advocate for improved outcomes. Our Washington office is staffed by Stephanie Salmon, a veteran lobbyist respected on both sides of the aisle, who represents us on legislative and OSHA matters. On environmental issues, we are represented by Jeff Hannapel and Christian Richter of The Policy Group, who have deep, productive working relationships with officials at EPA.

Recent AFS policy victories have saved foundries tens of millions of dollars. For example, AFS-sponsored research findings concerning existing non-HEPA sweepers were submitted to OSHA, which concluded that existing sweepers would be appropriate for meeting the agency’s silica standard. At a cost of more than $30,000 per sweeper, this victory alone saved millions of dollars. Another policy achievement in 2020, in which EPA imposed no new emissions limits on iron and steel foundries, also reflected extensive consultation by AFS.

In addition to our Washington-based team members, AFS has an active, member-led Government Affairs Committee which sets our overall policy goals. AFS holds an annual Fly-In in the nation’s capital, where metalcasters and suppliers meet face-to-face with lawmakers. The Fly-In had to be held as a virtual event the past two years, due to the pandemic, and we are looking forward to it returning to its in-person format in 2022. At the local level, our members often host elected officials for plant tours. These tours build first-hand understanding of what metalcasting is all about, and the elected officials enjoy meeting their constituents in the workplace. AFS also collaborates on policy priorities with state metalcasting associations, as well as certain national groups such as the National Association of Manufacturers. AFS members recognize the importance of advocacy and enthusiastically support these efforts.

BVM: How does AFS deliver educational programs to the industry?

Doug: The AFS Institute, the educational arm of the Society, has educated nearly 90,000 students since 1957. The Institute recently invested one million dollars to revitalize and refresh the curriculum. The core curriculum of 39 courses is scheduled throughout the year and can be taken in the classroom, live via Zoom, or via in-plant training provided in customers’ foundries. AFS also offers 110 modules of Foundry E-Learning which students can complete at their own convenience – in fact, a total of 4,399 modules were completed over a recent 12-month period. Over the past year, utilization of Institute training resources increased markedly. This is a positive development, as a skilled and trained workforce allows companies to optimize production, minimize defects, differentiate themselves from the competition, and demonstrate gratitude to the employees.

BVM: How does the organization foster innovation in the metalcasting industry?

Doug: AFS serves as a catalyst for innovation on several fronts. The first of those areas is ground-breaking research. AFS is currently funding more than $400,000 in ongoing casting research. These research project proposals are honed and referred by our 10 technical divisions to the AFS Research Board, which makes final decisions in terms of funding and prioritizing research. In addition to AFS-funded research, the Society is also coordinating a number of government-funded research projects with implications for national defense.

The second area in which AFS fosters innovation is through knowledge transfer and technology transfer. For example, AFS holds about 30 members-only webinars per year which are viewed cumulatively by about 2,500 members per year. These cover an array of research, technical and management topics. AFS also sponsors a technical discussion forum called Casting Connection that is home to 370 discussions in an average year. Also, AFS offers the world’s most expansive metalcasting library where 7,628 articles were downloaded in 2020. Any member of AFS can download an unlimited number of articles from the library at no further cost.

A third way that AFS fosters innovation is through our international activities. There is much that the world’s metalcasters can, and do, learn from one another in terms of stretching the standards of excellence. AFS publishes the peer-reviewed International Journal of Metalcasting, edited by Thomas Prucha, a leading figure in the metalcasting industry. Metalcasting experts from several dozen nations have published articles in this prestigious journal. AFS also participates in various global casting conferences. AFS is an active member of the World Foundry Organization (WFO). Denny Dotson (Dotson Iron Castings), a past president of AFS, currently serves on the Executive Committee of the WFO. As his term comes to an end, another AFS past president, Christ Norch (Denison Industries) will assume that role. I have had the privilege of representing AFS at events in China, Taiwan, Japan, Germany, Italy and Mexico. AFS also participates in GIFA, a once-every-four-years casting conference and trade show in Dusseldorf, Germany.

BVM: What is AFS doing to help foundries attract and retain employees?

Doug: I’m glad you raised this timely question. Our Quarterly Metalcasters Outlook Survey consistently finds that a shortage of workers is the number-one concern at foundries. (Shortages/prices of materials and concerns about OSHA/EPA policies now rank second and third.) AFS is helping foundries address the worker shortage in a variety of ways.

Metalcasting provides rewarding careers for those with the right skills and dedication – a message that AFS delivers through numerous channels. In the short term, AFS has produced a Metalcasting Careers Video that has been viewed more than 5,300 times on YouTube and the AFS website that highlights young people explaining why they love their career in our industry. We encourage our members to use the video in their recruitment efforts.

AFS is also publicizing information about ways that foundries are finding success in worker recruitment and retention, supporting the Future Leaders in Metalcasting and Women in Metalcasting groups, sponsoring a Jobs Board, supporting 41 College Student Chapters of AFS, inviting students to attend CastExpo at no cost, publishing the Melting Point magazine and website for students, providing resources for Manufacturing Day events at our member companies, offering several college scholarships, collaborating with the Foundry Educational Foundation (FEF), holding the IJMC-FEF Student Research Competition, and providing free first-year memberships in AFS for graduating student chapter members. These steps, taken together, are all meant to support the foundries as they undertake their short-term and long-term recruitment and retention efforts.

AT A GLANCE

American Foundry Society (AFS)

What: An organization serving the metalcasting industry and its supply chain

Where: Schaumburg, Illinois

Website: www.afsinc.org or call 847-824-0181