The Probst Group

Rethinking wastewater

Business View Magazine interviews representatives from The Probst Group, as part of our focus on best practices in the wastewater engineering sector.

In the U.S., old school technologies for removing wastewater impurities still have a stronghold due to tightening environmental regulations and various funding and infrastructural challenges. But the Probst Group, a wastewater engineering and food and beverage consulting firm out of Brookfield, WI, is well-poised to transform that paradigm as one of the pacesetters among a new generation of innovators who are reimagining our current means of treating, paying for, and profiting from wastewater.

“Wastewater is looked at as this archaic system,” says Garry Gibson, Business Development Manager for the Probst Group. “It’s always the last thing somebody’s thinking of when they’re building a food or beverage facility.” “We’re working with some potentially transformative technologies right now, including a microbiological fuel cell technology that could really be a game changer,” adds owner Henry Probst. “We’re looking at piloting that at a few different facilities around the country. We’re also experimenting with plasma-based water purification, something that could alter the face of how we approach wastewater treatment projects, as well as reduce the cost profile for the client.”

Industries that use large amounts of water—the food and beverage realm in particular—are increasingly on the lookout for just these sorts of sustainable solutions – ones that can improve filtration efficiencies, reduce maintenance, decrease energy usage, and cut operating costs.

“I’m a 3rd generation wastewater engineer,” reveals Probst. “My grandfather traveled the U.S., installing some of the first secondary treatment systems related to the Clean Water Act limitations. My father started in the municipal realm but quickly gained an interest in the industrial side. He started his own consulting and design-build firm back in 1988 called Procorp Inc., servicing the food and beverage market space. I joined him in 1991, balancing work and full-time studies in civil and environmental engineering at the University of Wisconsin-Madison. Together, we developed some of the first processes for enhanced biological phosphorus removal. In 2014, I purchased the firm outright from my father and have since gotten into bigger and better projects, continuing with the excellent service and partnerships that were formed before I became the sole owner.”

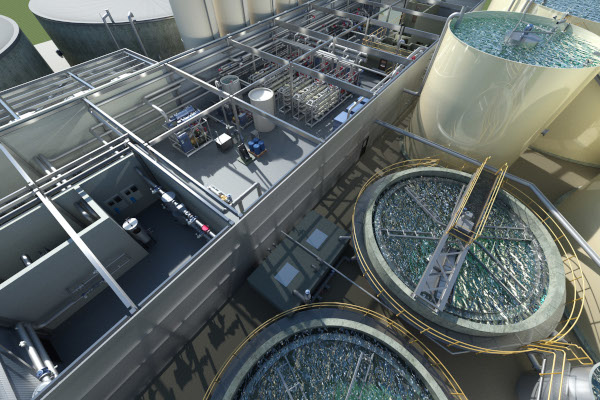

3D rendering for a full treatment facility that will utilize both aerobic and anaerobic treatment to achieve treatment goals.

Today, the Probst Group comprises a well-rounded team of engineers, scientists, designers, and business developers stationed in various parts of the country. “We’re nation-wide, coast to coast,” says Probst. “We have satellite employees that actually operate our Brookfield facility. That’s one of the unique things we do on the industrial side. We handle permits, consulting, and design. We do design-builds. We have an operations arm as well. We offer a menu of services, including oversight management of our clients’ staff, or complete contract operations if it’s warranted and desired.” The firm’s approach is consultative and highly-tailored. They begin by listening to their clients’ needs and following through with the proper application of process technology. “We don’t build a box that they’re going to grow out of,” Probst insists. “We work with them to anticipate the next bottleneck and offer them a solid action plan for expanding, increasing capacity, or addressing future limits.”

With the promise of more efficient, sustainable, and cost-effective wastewater management solutions, the Probst Group has shown aggressive growth, particularly over the last three years. “We’ve developed a customized set of components that are market beaters,” explains Probst. “They can outperform just about anything else out there.” According to Probst, the firm’s success boils down to one specific advantage over other consulting entities: “We’re hands on. We don’t buy a solution off the shelf. Our process designs are our own and we design them based on our depth of experience and expertise. We run them through our own trials and research. I grew up, not only designing and constructing, but also commissioning, starting up, and operating many of the plants that we’ve built. We’ve put our designs through their paces and seen what they can do. We’ve been fortunate enough to partner with clients to be able to innovate key improvements on some of the base designs and give them extra efficiency, process flexibility, and performance.”

Developing an intimate knowledge of their sector has proven pivotal, both to their mastering the process and to adding further value to the wastewater treatment projects they’ve taken on. “We do focus on food and beverage,” Probst admits. “In the history of the company, we’ve done more dairy projects – cheese and yogurt – than just about any other firm. We do a lot of organic food. We’ve done plans for Mott’s and Cliffstar, for instance. The core of our expertise really has been the high organic loads.”

The Probst Group has met the enforcement of stricter water quality standards within the food and beverage space with more sophisticated process measurement systems. “We have a beta site in operation where we’re doing a trial-based data selection system,” reveals Probst. “It collects all the log sheet data from our operators, the certified lab data and process observations, stores them in the cloud on a continuous basis, and will allow us to go in and use some analytics for fault detection and predictive analysis. Once we get multiple sites involved with this data collection system, we can take that information, stack every digester we have participating, and look at how they’re responding. Really get down into the base kinetics of the process. Our process engineers will then be able to unlock additional process benefits and flexibility. With machine learning and the analytics engines, we’ll be able to take our automated control systems to the next level, to allow enhanced reliability and more intelligent automated response – far superior to what we’re seeing in today’s general project availability.”

As part of the operations services offered by The Probst Group, our lab technicians and specialists are able to provide analysis and sampling for monitoring, reporting, and troubleshooting. Sampling shown is in the lab onsite in a WWTP facility operated by Probst.

The goal is to get to the point of full utilization of that automated control system, as the Probst Group delves further into water reclamation. Integral to this plan are the firm’s partnerships with companies including Lee’s Contracting out of Little Chute, WI, Dorner out of Sussex, WI, and Tank Connections headquartered in Parsons, KS. “We tend to gravitate towards companies that share our passion for serving the client and providing a project that we’re all very pleased with in the end,” says Probst.

“Our approach has always been a strong partnership, really focused on the client and their satisfaction,” Probst re-emphasizes; “a long-term partnership, not just a project there and gone. I still have my first clients that I ever cold-called up in Marshfield, WI back in 1991. We’re doing another construction project for them this year.”

“What I see as the separator for this company is the focus on technology and innovation,” shares Gibson. “There are innovations in the wastewater industry that the Probst Group is doing right now that can make wastewater systems more efficient in general. There’s a biogas created in wastewater that can be used to heat the boilers or otherwise fed back into the utilities. That’s what we’ve been focusing on over the last few years to differentiate ourselves.”

“A wastewater facility isn’t just a result,” adds Gibson. “It can be something that’s economically feasible, better for the environment, and sustainable to the future.”

AT A GLANCE

WHO: The Probst Group

WHAT: A wastewater engineering and food and beverage consulting firm

WHERE: Brookfield, WI

WEBSITE: www.probstgroup.com