Salem Fabrication Technologies Group

providing the right products at the right time

With products and solutions second to none, Salem Fabrication Technologies leads by example

Salem Fabrication Technologies Group (Salem) is a leading fabrication machinery, tooling distributor, and supplier that carries high-quality products manufactured around the world for the commercial sector. For nearly 90 years it has supported glass fabricators and glazing professionals with the products and tools they need to exceed their own customer needs, from tooling and material handling to parts and supplies and a range of other solutions.

The end products made by the talented craftsmen who purchase from Salem are all types of glass and related window products, from home or commercial windows to shower and sliding doors, partisans, and conference room centerpieces. Salem also sells non-glass products that can support a glass or window infrastructure, such as a frameless door. Its professionals support superior solutions for a vast number of industries, including glass, stone, vision for optical and ophthalmic, and advanced surfacing for aerospace, solar, optics, exotic metals, and other specialized uses.

Mike Willard, CEO

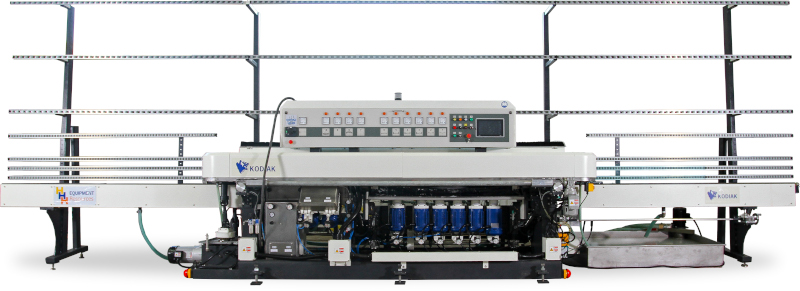

The company’s international reach is impressive. Salem has provided equipment and supplies made in North America and Europe, with an emphasis on high-end lines from Italy for many years. Now Salem has introduced a line of Asian-made equipment, specifically a glass tempering line, along with grinding and polishing equipment. These carefully manufactured products are made in such countries as China, and are added to goods made from Taiwan and South Korea that the company has been providing for many years, said Salem CEO Mike Willard.

While Salem serves a sizable, niche market, it also continues to invest time and money in understanding what its customers want. Today, that increasingly involves automation and greater efficiencies. Willard believes that finding popular products that feature automation will be a “huge factor in our success in the coming years.” One option is the use of robotics to help with menial or repeatable tasks, allowing companies to repurpose their employees to focus on more projects and tasks that require critical thinking.

Artificial intelligence plays a role in the automation trend as well. Salem installed internal software in 2022 that supports automated and AI-driven customer ordering processes. This allows Salem to more effectively predict future orders that will be needed, while alerting those customers of a forthcoming need, based on past order history. According to Willard, this has provided a significant amount of value to Salem because it can increase revenue and provide an added layer of convenient customer service.

“The customer service aspect has been very useful for us,” Willard said. “It helps us with budgeting because many of our customers have reliable ordering patterns. We are finding that any technology that allows the customer to benefit from automation is extremely valuable.” This can include automation that is a part of distributed products, or automation used by Salem that helps solve a customer’s need or saves them time.

This is especially important because Salem’s customers operate in a very competitive market where they compete with other fabricators and skilled professionals. For example, customers often work with architectural glazers to compete for projects needed by a large office building, commercial gym, warehouse, or retail store.

Salem though is more than just a distributor. Its leaders understand that tooling made from inferior materials or processes does not last long and can lead to increased maintenance and longer production times. Fabrication tooling is selected by Salem’s product specialists after intense research, performance testing and durability. Whether customers use diamond or resin cup wheels, polishing compounds, core drills, routers, coolants, or flocculants, they will have the reassurance that it’s been thoroughly vetted for proper use.

Recovering from COVID-era solutions

The economic impact of COVID was somewhat significant for Salem but has been improving over the last year. Added tariffs from China, combined with outrageous shipping costs from Asia, hurt company margins for a bit, Willard said. The costs of shipping containers rose 10 times and by $4,000 to $5,000 on average in 2020, 2021, and parts of 2022.

Fortunately, most of those costs have fallen back to near pre-COVID levels. The tariff that China had reinstated in the early days of COVID also has been suspended, helping to stabilize prices. Yet that experience helped Salem to more efficiently manage its costs, a trait it continues to improve upon today.

The other COVID challenge common for many industries has been the skilled labor shortage. However, that issue has largely not materialized with Salem, which is based in Winston-Salem, North Carolina but has offices in Pennsylvania, California, and the state of Washington along with a presence in Canada. There is little employee turnover at the company in part because employees have an ownership stake in the business. Salem operates as an employee stock ownership plan (ESOP).

The company had record EBITA earnings in 2022, says Willard. Last year, employees also received a “stay” bonus to encourage team members to remain committed to Salem which averaged around $1,500 per employee. Many employees also received two pay increases.

“Little things like these bonuses and other types of recognition definitely help,” says Willard.

ESOP provides financial freedom for employees and corporate stability

When Salem became an ESOP in 2000, it marked a significant change in the company’s structure. Within five years of that move, Salem became 100 percent owned by employees, and since has navigated economic peaks and valleys from the Great Recession to the 2020 COVID year. Today about 75 employees have various levels of ownership vesting but have been able to share in the record growth that Salem has experienced.

There are many advantages to the ESOP model, Willard says, but one is the ability for employees to build personal wealth that will support their retirement years. As mentioned above, the company also pays regular bonuses based on overall financial performance. These payouts do require Salem to maximize revenue while minimizing unnecessary expenses. Financials are regularly analyzed to ensure budgets and targets remain on track, Willard says.

“As an ESOP, we ask employees for their sweat equity,” Willard says. “That includes giving 110 percent every day. The reward is that (the company) contributes money to their own account without asking for them to contribute any money on their own. It’s a nice nest egg for our employees when they retire.”

In addition to the ESOP ownership funds, Salem employees are eligible for a 401K plan with company matches and still can draw on their Social Security at retirement. Willard says that many retired employees have shared stories with their former co-workers about how they have been able to afford long-term, dream vacations based on their time working at an ESOP that might not have been possible otherwise.

Initiatives for 2023-2024

Willard outlined a few corporate initiatives for the next couple of years.

One is to introduce more robotic applications among its distributed products. A second is expanding the company’s maintenance and repair reach and revenue. Salem employs nearly 20 master service technicians who travel to customer sites for installations and repairs. This is a growing part of the business with consistent revenue opportunities and Willard hopes to hire at least 10 more technicians in 2023 to support the company.

Corporate acquisitions are possible in 2023 and beyond. Willard says Salem’s employee-owners are currently in discussions with a small but highly successful company that would add value if the deal is consummated. There are a wealth of potential opportunities like this one as many Baby Boomer entrepreneurs are retiring and looking for buyers for their companies. Willard refers to it as the “silver tsunami,” given the fact that more Baby Boomers are seeking retirement every day.

Finally, more customers are requesting assistance from Salem in executing plant relocations, often to a different part of town or somewhere close to an existing location. Salem professionals excel at managing a plant relocation in as little as four to six days. This can include moving major equipment and a significant number of details that are critical to success.

Says Willard, “We’re always looking to expand our reach and the services we provide. It’s a great way to support our continued growth.”

AT A GLANCE

Salem Fabrication Technologies Group

What: Leading fabrication machinery, tooling distributor, and supplier that carries high-quality products manufactured around the world for the commercial sector

Where: Clemmons, North Carolina

Website: https://www.salemftg.com/

PREFERRED VENDORS

Dr Lubricants – www.drlubricants.com

For over three decades, DR Lubricants (DRL) has been at the forefront of providing tailored industrial fluids and lubricants to businesses. Headquartered in Fort Wayne, Indiana, DRL is a trusted partner for many businesses across different industries.

One of DRL’s success stories is its partnership with Salem Fabrication Technology Group. Together, they developed the Salem product line of consumable lubricants, which has expanded their offerings and boosted profits to new and existing customers. DRL’s commitment to quality and innovation has helped Salem to exceed their customers’ expectations.

DRL’s extensive experience in multiple industries allows them to provide customized solutions that cater to each client’s specific needs. Whether it’s developing private label lubricants or offering custom blends for niche applications, the team of experts at DRL can provide solutions that enhance your business offerings.

DRL’s commitment to quality is evidenced by its ISO 9001-2015 certification, which ensures that every aspect of the business is held to the highest standard. Additionally, DRL’s team of experts can train and support your sales staff, provide lab services, and offer technical support to ensure you achieve your business goals.

As an extension of its clients’ businesses, DRL provides comprehensive support, from product development to inventory management and nationwide shipping. This approach frees up time and resources, allowing businesses to focus on other aspects of their operations.

DRL’s approach to doing business is simple and seamless. They pride themselves on building lasting relationships with their customers and providing unmatched support every step of the way. Whether you’re looking for off-the-shelf solutions or custom blends, DRL has the expertise and resources to help you achieve your goals.

In conclusion, DRL’s commitment to quality, innovation, and customer satisfaction has made it a reliable and trusted partner for businesses. Contact DRL today to learn how they can help you achieve your business goals.

Marsh McLennan Agency – www.marshmma.com

Marsh McLennan Agency (MMA) provides business insurance, employee health & benefits, retirement, and private client insurance solutions to organizations and individuals seeking limitless possibilities. With 9,900 colleagues and 170 offices across North America, MMA combines the personalized service model of a local consultant with the global resources of the world’s leading professional services firm, Marsh McLennan (NYSE: MMC).

IGis –