Business View - November 2014 23

er/Ground Worker; 2) Ground Technician; 3) Elevated

Tower Technician I; 4) Elevated Tower Technician II;

5) Lead/Foreman. This skills-based resource will ulti-

mately serve as the impetus for the development of

a national training standard, complete with industry-

embraced guidelines and curriculum. The standards

and mandatory training that are developed will create

a smarter, safer, more capable tower technician who

is able to provide the wireless owner with the safe and

quality build-outs necessary to meet today’s demand.

The Standardization Requirements Subcommittee is

working toward creating a standardized checklist of

requirements that can be mutually agreed upon, ad-

opted, implemented and adhered to by companies in

the industry. The ultimate goal of this subcommittee

is to raise the bar and standardize safety expectations

on critical issues involving contractor evaluation. Is-

sues such as pre-hiring practices, employee screen-

ing, insurance coverage, substance abuse testing, fall

protection, training verification and many others are

being scrutinized as a result of the work of this sub-

committee.

One of the most common questions in the industry re-

volves around how to regulate the training that emerg-

es from this effort and how will that be required? The

Governance Working Group is exploring the possibility

of developing a nationally recognized third-party certi-

fication firm to administer or govern the subject matter

created by the training. The training certifications for

each individual will be reviewed and verified with docu-

mentation and updated accordingly as the technician

goes through each level of certification. Our vision is

that all of the tower industry workforce will ultimately

be trained and certified to this standard.

A Manufacturing and Engineering Solutions Working

Group has also been established to explore manufac-

turing and engineering solutions to some of the safety

hazards confronting the workforce. This working group

is engaging with industry manufacturers and engi-

neers to discuss what advancements can be made to

fall protection equipment and tower structures to help

make the industry safer for the challenges elevated

workers are confronted with on a daily basis. For ex-

ample, the working group is consulting with equipment

manufacturers to challenge them to develop a “smart

hook” or “smart lanyard” automated device that would

remove the human error element and ensure that a

technician is properly tied-off on the tower at all times

when working on towers at elevated heights.

Another major initiative of the Wireless Industry Safety

Task Force is the 100% Tie-Off 24/7 Awareness Cam-

paign. One of the early issues identified as a result of

the task force’s collaborative efforts is the fact that

many of the tower-site accidents that compromise safe-

ty involve situations where the tower technician was

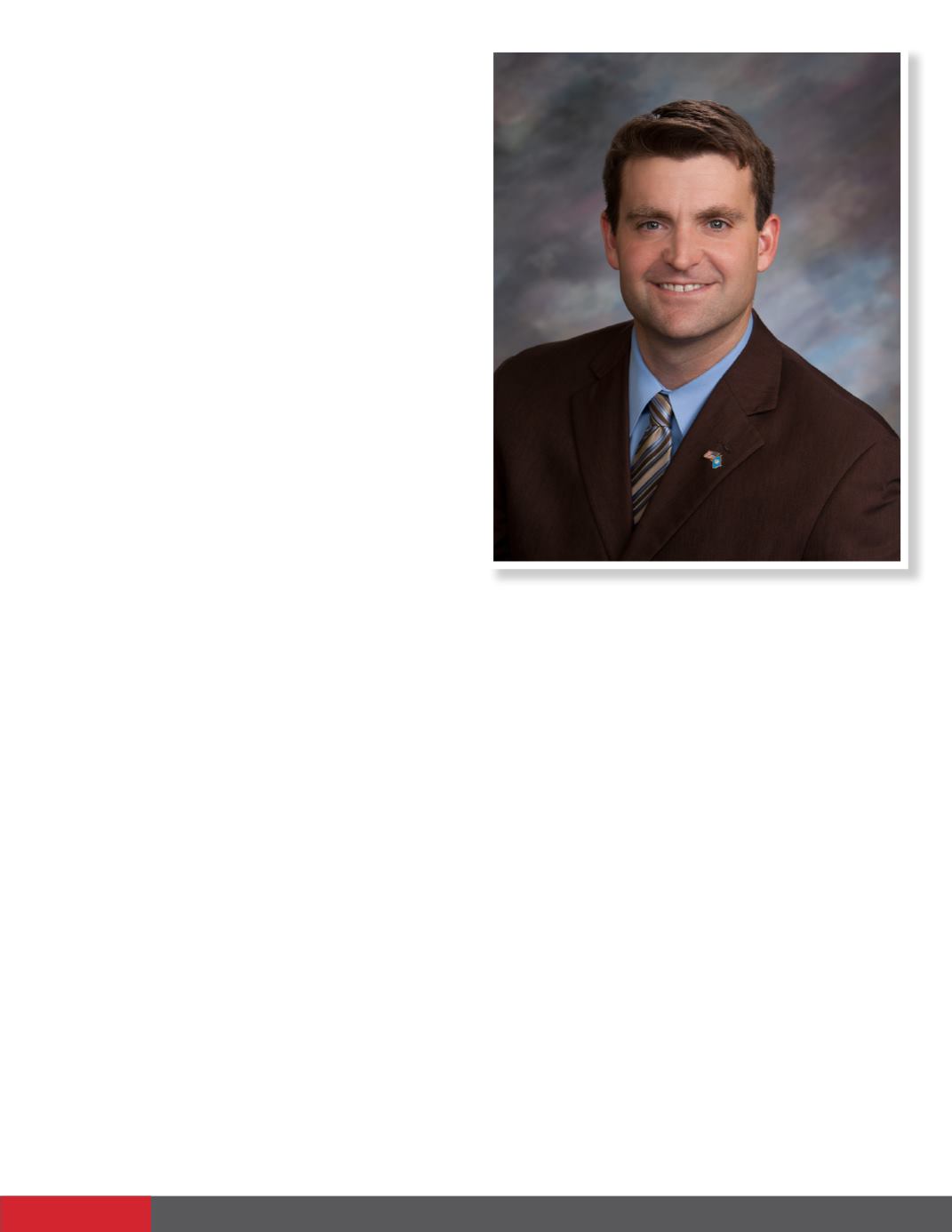

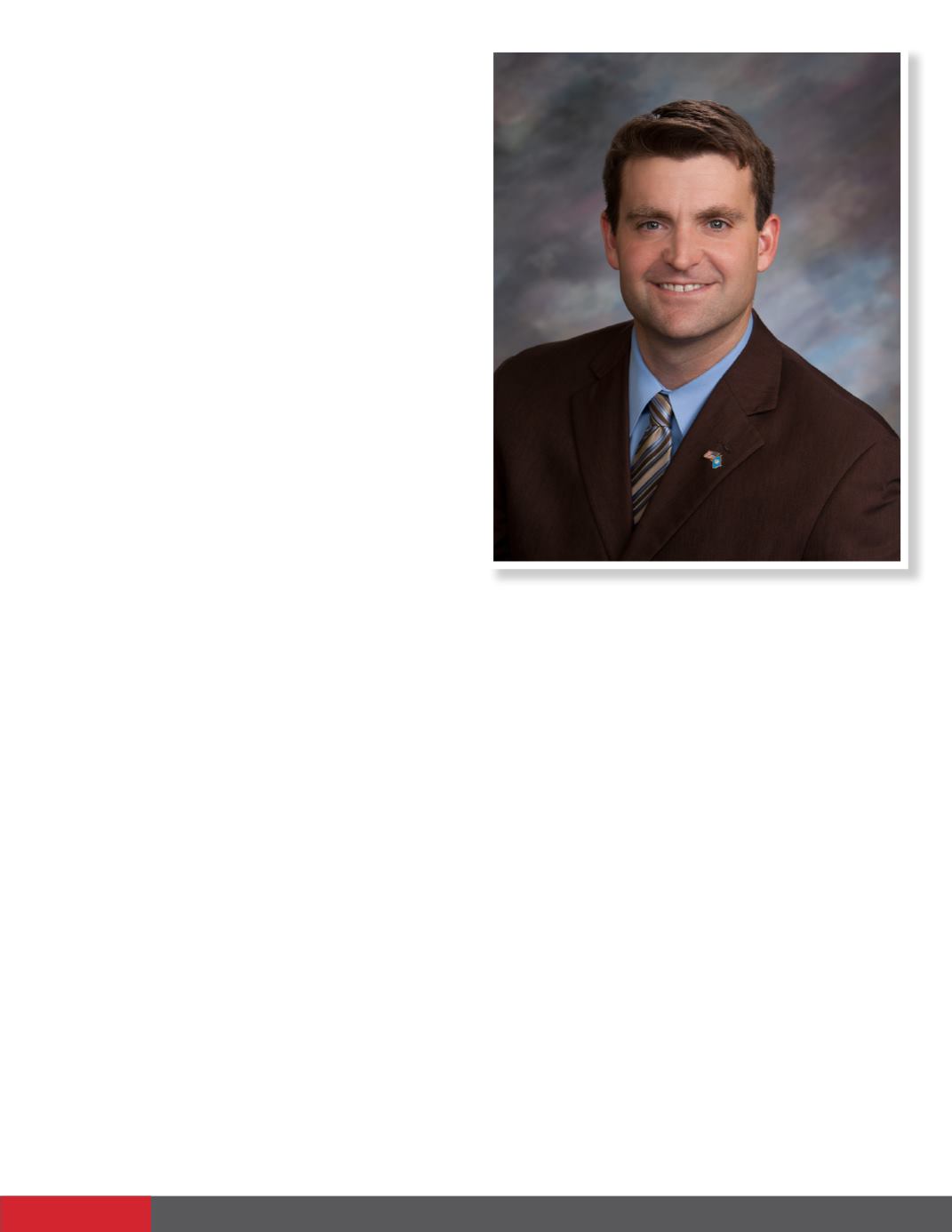

Todd Schlekeway

CONSTRUCTION