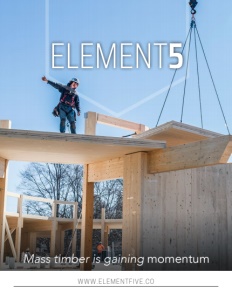

Element5 LP

Mass timber is gaining momentum

Business View interviews Patrick Chouinard, Founder/VP Marketing Strategy & Corporate Communications, Element5, for our focus on Mass Timber Construction

The construction industry is one of the most significant contributors to CO2 emissions worldwide. Cement and steel, key ingredient in building materials, account for 16 percent of global CO2 emissions, equivalent to billions of tons of CO2 added to the atmosphere annually.

While both industries are rapidly innovating to reduce emissions, evidence shows that they cannot stem rapidly rising atmospheric CO2 levels. The only near-term remedy is alternative building materials and mass timber, the world’s most flexible and only renewable building material, sits at the top of that list.

Mass timber uses modern technologies to glue, nail, or dowel wood products together in layers, creating robust, durable, and sustainable building materials with a high strength-to-weight ratio. These materials can be large structural panels, posts, or beams that are exceptionally strong and versatile in their applications.

Element5 is Ontario’s only mass timber manufacturer and specializes in designing, fabricating, and assembling modern timber buildings. The company has its headquarters in Liberty Village, Toronto, Ontario and a separate manufacturing facility in St. Thomas, ON.

Element5 supplies five types of mass timber products: CLT (Cross Laminated Timber), Glulam (Glued Laminated Timber), CLIPs (Cross-Laminated Insulated Panels), Boxx Panels, and NanoCLT. The company’s services span many timber construction areas, including cost consulting, design consulting, engineering, fabrication, and assembly.

Although the firm has traditionally sold mass timber components, it is now moving towards standardized builds that integrate most finished parts of the structure. As Element5 VP of Market Strategy and Corporate Communications Patrick Chouinard explains, “When selling our CLIPs panels, we recognized a huge opportunity in the industry for a high-performance, prefabricated envelope panel. Previously, we delivered the panels to the site with the CLT interior layer only; cladding and windows were site-applied. We’re creating a fully unitized system where the panels arrive with the cladding and the windows and doors pre-installed for faster assembly.”

Besides selling specialized timber products, the company is also developing affordable housing solutions with complete multi-unit structural designs that it can deliver as an off-the-shelf build.

Element5 has rapidly grown over the last two years, from just 10 employees in 2021 to 85. The entry of investors is the leading cause of this growth, which has also seen the company move to a larger facility. “Last year, we moved to our new 137,000 square foot facility in St. Thomas,” says Chouinard. “We are also building another equally sized facility right next to the current one.” The St. Thomas facility is certified to the North American standards for CLT manufacturing and has been fully operational since April 2021.

As the company has grown over the past year, one of the areas it addressed is hiring new staff for its facilities. Although most companies are grappling with labor shortages, especially for skilled trades, Element5 has not, and there’s an excellent reason why.

“We’ve built a modern, collaborative and dynamic work environment that appeals to young, talented, highly educated professionals,” says Chouinard. “The people we hire tend to be motivated by the fact that we’re revolutionizing the construction industry in a way that has a huge environmental benefit. In addition, they know mass timber is a great business opportunity and want to get in at the forefront of an industry in huge growth mode and one that’s making positive contributions to communities through affordable housing.”

Another aspect of Element5’s corporate culture that attracts talented young professionals is its focus on independence, innovation, and creativity – allowing workers to thrive in their individual capacities within the company. The company’s corporate office location in the swanky Liberty Village adds to this charm, giving employees an idyllic location with all the trappings of a modern, stimulating, and dynamic work environment.

Element5 primarily manufactures CLT and Glulam at its St. Thomas facility, besides lesser quantities of complimentary engineered wood products. It plans to ramp up Glulam and CLIPs production in the new facility currently in design, with additional capacity to manufacture larger members and more comprehensive prefab envelope panels.

One interesting thing about the company’s operations is that its production was not affected by supply chain disruptions caused by the Covid-19 pandemic and subsequent economic shocks. “Surprisingly, the pandemic affected our operations only to a minimal degree,” says Chouinard. “We are fortunate to be in control of our supply chain, from the forest floor to the finished product. Our largest investors are also the largest investors in sawmills in northern Ontario, so although Element5 doesn’t own forests, we still control the entire supply chain.”

Another factor that the company’s investor relationships addresses in favor of Element5 is the spike in prices of timber products. “The price of lumber has gone through many peaks and troughs over the last few years,” says Chouinard. “Although we’re still subject to volatility, our investor relationships smooth out some of the peaks and troughs, resulting in more consistent, predictable pricing for wood. This favorable pricing puts us at a significant competitive advantage over other manufacturers without the same control over their supply chains.”

Whereas Element5 has traditionally provided mass timber services for custom projects, it sees more growth in standardized buildings that it can mass produce quickly, efficiently, and cost-effectively. Its push into standardized builds is informed by market intelligence showing a market gap that mass timber can quickly fill.

“The light wood frame industry serves the four stories and fewer market niche, while the concrete and steel industry dominates twelve stories and above,” explains Chouinard. “However, the missing middle is the four- to twelve-story range, which is where we’re seeing a huge opportunity for mass timber because that’s where it makes the most sense.”

While the company still works on custom projects, it has developed standardized projects that it calls Profiles, using designs optimized for certain buildings and suited for mass timber. “Profiles began when we sat down with one of our associate architects to develop a mass timber, affordable housing solution,” says Chouinard. “Without an actual project in mind, we designed, engineered, and optimized the designs to lower costs and facilitate constructability. During this process, we secured an affordable housing opportunity – the YWCA in Kitchener, Ontario. We submitted a proposal for the design-build project, and our proposal undercut every other bidding affordable housing manufacturer in the province of Ontario, including light wood and precast concrete.”

With a great need for affordable housing, winning the YMCA bid allowed Element5 to dispel the belief that mass timber is more expensive than other forms of construction. “To everyone’s surprise, we were the lowest bidder and won the project, which we delivered, contract-to-occupancy, in under a year. We have productized those designs and have a huge pipeline of opportunities as part of the solution to the affordable housing crisis.”

The company is currently tweaking the designs to supply market segments like retirement homes, student residences, and hotel sectors. Assisting the company are design and architectural partners like Edge Architects led by Matt Bowen and Tye Farrow of Farrow Partners.

As the construction industry grapples with the affordable housing crisis, Element5 is transitioning from a shotgun approach to projects to targeting projects that better align with resolving this crisis. At first, the company tried to approach each project as a clean slate, which came with some challenges.

Chouinard acknowledges, “Most of the projects we won were designed as either concrete or steel buildings because that’s what the industry knows how to design and develop. We’d then get the question, how much would this building be if it was in mass timber and end up investing a tremendous amount of time and energy handholding those buildings from early stage design through to manufacturing. We decided instead of continuing with custom-only projects, we would develop an affordable housing solution called the Attainable Series. These are pre-engineered, predesigned building typologies targeting the middle-market, which lies at the epicenter of the affordable housing crisis. Because we can build the Attainable Series competitively, maybe we have created part of the solution to the affordable housing crisis.”

Element5’s future looks nothing but rosy, at least from where Chouinard sits. With hundreds of mass timber projects underway in Canada and the United States, mass timber is no longer a theoretical concept but a tsunami gaining momentum.

“If you look at Europe, mass timber is a major part of their construction industry, putting them maybe 30 years ahead of us,” says Chouinard. “Considering that the North American market is much larger than the European one, it’s a massive opportunity for anyone in the mass timber industry right now. For Element5, our geographical location in Ontario gives us access to the Central U.S. and the Eastern Seaboard, while in Canada, we are perfectly situated to access the vast forestry resources in the region. Element5 is currently the only mass timber manufacturer in the province, creating a great business opportunity, as we could not be any better situated for the unfolding mass timber revolution than where we are right now.”

AT A GLANCE

Element5 LP

What: Full-solution mass timber manufacturer and service provider

Where: St. Thomas, Ontario

Website: www.elementfive.co

PREFERRED VENDORS

Synergy Resources – www.synergyresources.net

Element5 was founded on the principle that quality materials are essential to quality construction. Synergy’s success, likewise, is built upon the understanding that in all things, quality and attention to detail are critically important.

When Element5 set out to build a world-class manufacturing operation from scratch, they knew they needed a powerful technology platform to ensure efficiency and profitability. Synergy Resources offers deep expertise in manufacturing, supply chain operations, and distribution; combined with decades of experience in business information technology. Element5 chose to work with Synergy in large part because they recognized our successful track record with other companies in the construction materials industry.

Synergy is committed to exceptional professional services and software. We take the time to get to know every customer, including their unique requirements, aspirations, and challenges. Then we develop a detailed plan for success, and we work diligently with our clients to turn that vision into a reality.

Our customers see Synergy as a long-term partner and trusted advisor. We view our customers’ success as a reflection of our own aspirations to achieve excellence in everything we do. We’re proud to have the opportunity to work with Element5, and we look forward to their ongoing success.

Learn more about Synergy at www.synergyresources.net

Infor Canada Ltd. – www.infor.com

How do you run your business? Are you doing weekly planning on a whiteboard? Do you keep track of inventory in spreadsheets? Can you measure performance against key performance indicators? Does your business have lots of data, but it exists in silos and requires time-consuming and error-prone manual processes before it can be shared across business units?

In today’s fast-moving, increasingly competitive business environment, processes that are “good enough” are no longer good enough. Today’s organizations need complete enterprise-wide visibility and the ability to collaborate across the business. They need the flexibility to quickly respond to a changing market and grow and expand the business to take advantage of new opportunities—ideally, before the competition. Organizations that rely on aging systems and manual processes will quickly fall behind.

Not only do modern ERP systems touch and connect virtually every operational corner of a business, they also help foster a data-driven mindset across the business. In doing so, they empower key stakeholders to leverage this information for critical decision-making that can grow the business and increase the bottom line. Infor’s purpose-built software for industrial manufacturing helps manufacturers turn data insights into greater productivity and powerful customer experiences—sustainably and profitably.