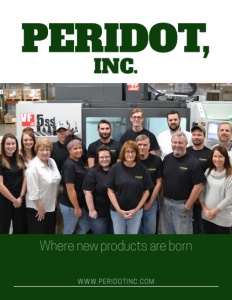

Peridot, Inc.

Where new products are born

Business View Magazine interviews Dave Hockemeyer, President of Peridot, Inc., as part of our focus on the additive and prototype manufacturing sector.

It’s a tale of life lessons, faith, and three engineers blessed with the skills and drive to forge a path in advanced manufacturing. Based in Hoagland, Indiana, Peridot Inc. is a visionary family business established in 1997 by David E. Hockemeyer and his sons, Brian and David J. (Dave), at a time when the emerging technology of rapid prototyping (3D printing) was starting to gain practical application. The brothers were engineers with experience in the polymer and metal casting industries, and their dad had 37 years of diverse engineering experience under his belt with a large truck OEM. Together, these three engineers saw the myriad of possibilities for 3D printing technology in the product and tooling fields. So, they wrote a business plan, managed to acquire some financial backing from the local bank to accompany their own investments, and dove right in. An impactful event earlier that same year, the unexpected and sad passing of a third son, Jonathan, had made the family realize just how short and fragile life can be. Time was not to be wasted. In his honor, the company was named Peridot (pair-uh-doe) – a semi-precious mineral and birthstone for the month of August, the month Jonathan was born.

Peridot’s company president, Dave Hockemeyer, recalls, “We started with one LOM and one FDM machine and 1,500 sq. ft. of office space. Our business plan was to use this new technology to print models that engineers could design on the screen but rarely were able to evaluate it until it got to production. We saw an opening in northeast Indiana and the Great Lakes region for such a technology that was only around in Chicago and Detroit. For a couple years, we printed only 3D models, which ultimately led to customers saying, ‘Thanks for the model, now can we have ten more, but a little bit tougher?’” That’s how Peridot migrated into the process of using low-pressure polyurethanes to produce cost-effective functional components. In additional to polymer components, Peridot’s customers began asking if they could get “10 or 20 of these as metal castings.” “So,” Hockemeyer recalls, “we started making foundry patterns; and working in partnership with foundry partners in our region and completing the finish-machining to produce a turn-key metal solution.”

Fast forward to 2020, Peridot’s operations have grown considerably since its first day in 1997 and now include seven in-house additive manufacturing machines; a model shop for finishing and polymer molding and vacuum-forming; a CNC machine shop; and a team that does kitting and sub-assembly. Along with the prototyping and manufacturing resources, the Peridot team includes engineers and a crew of technicians to provide the foundation behind the various services and capabilities. This team of approximately 20 skilled technicians keeps the 18,000-sq.-ft. Hoagland facility running at top efficiency. “The majority of sales come from within an eight-hour radius of northeast Indiana, but long-time customers reside in Canada, on both U.S. coasts, and Mexico,” states Hockemeyer.

Peridot’s largest customer is a mid-sized manufacturer of off-highway equipment – including agriculture, recreational, and boating products. Both the prototyping and production capabilities together have allowed Peridot to forge a unique vertical relationship with this customer, as well as other customers, to make Peridot an important strategic supply partner. “We do a lot of prototyping for them in the CNC machining shop making metal components and the plastics shop, making molded or 3D printed components,” says Hockemeyer. “With our supply chain management, we manage several part numbers for them, which we manufacture internally or procure from around the world. We have very good off-shore partners, as well as domestic suppliers. The various components come to our facility, then we kit, sub-assemble, and inventory finished goods, then we ship on-demand.” Among Peridot’s diverse customers are Tier 2 and Tier 3 automotive companies, medical companies, and a myriad of many other companies producing various industrial products.

Referencing a competitive edge, Peridot denotes its five swim lanes of capabilities: additive manufacturing (aka 3D printing); polymer molding; metal castings; CNC machining; and supply chain management. Hockemeyer points out that Peridot’s customers appreciate that instead of writing multiple purchase orders for a program that requires several processes, Peridot can bundle the entire package together for improved efficiencies and provide a center-point of responsibility for the turn-key solution. As a small group of engineers with the technical competency to accompany that, the firm also takes care of ancillary special processes when needed, under one PO. Whether an entrepreneur needs a single 3D printed prototype of their proud invention or an OEM needs a multi-faceted manufacturing solution, Peridot is comfortable adapting to meet the customer’s specific needs.

While there is competition with other 3D printing service bureaus, as well as some progressive foundries and machine shops, Peridot’s ability to seamlessly join it all together as a one-stop technical solution is only matched by a handful of other companies in the U.S. This adds another proud achievement to the Peridot story – at 23 years old, the company hails as one of the oldest 3D printing service bureaus in the nation.

But sitting still has never been part of the Hockemeyer DNA; if anything, success has fueled the Peridot momentum. In 2016, the Hoagland facility underwent a 40-percent expansion and new equipment is added to their stable regularly, including, most recently, the installation of a new additive manufacturing machine called an SLS (selective laser sintering). As Hockemeyer explains, “The SLS process has been around since the ‘90s, but it’s now a natural fit for us, in that we already have the SLA technology and FDM technology, and now the SLS – three additive manufacturing technologies in our facility.” The Peridot team is excited because their goal is to use additive manufacturing not just for prototyping, but for actual production level components in volume. In addition to adding the process, the material may be the most exciting aspect of this growth. “Our material supplier is a global materials leader, BASF. They’re now into the additive manufacturing arena and we are one of the first launch points in the world to be running their product called PP1200 (a polypropylene polymer). It will be a new capability for Peridot, providing production level parts from an additive manufacturing machine. This is a manufacturing alternative to injection molding that we’re really excited about,” comments Hockemeyer.

With large players from the engineered material field, like BASF and others joining the additive manufacturing arena, it’s becoming a whole new game. As Hockemeyer attests, “The machines have been here for a while, but the material has been a limiting factor to achieve performance characteristics required by production level applications. That’s why we decided to partner with BASF and felt this was the right time to launch this endeavor into the powder-bed fusion technology. Our commitment to this launch is part of a winning triangle, in that BASF is the innovative material producer, and Peridot is the service company that will manufacture components on the advanced SLS machine technology built by Prodways.” A common question asked when additive manufacturing is discussed is “will AM replace injection molding, cast metals, CNC machining, or other conventional manufacturing processes?”, and Hockemeyer is quick to reply, “no, definitely not – the advancements and technologies that additive manufacturing bring to the market are, and will be, complimentary processes to current conventional methods and likely will develop advantages in specialized applications throughout the manufacturing fields that require polymer, metal, and even biological components.”

Going forward, the future plans for Peridot are to bring more manufacturing resources in-house to reduce the supply chain. In the area of metal castings – a key cornerstone of the business – the aim is to have the ability to pour metal in the facility; also, to bring injection molding into the facility; and continue to enhance its additive manufacturing arsenal. These objectives provide a synergistic approach to grow vertical in the way of doing more production work – the more complex the program, the more Peridot excels at providing tailored solutions.

Innovative partnerships and long-standing relationships are priceless and Hockemeyer acknowledges their team has been blessed in that department. For instance, a growing relationship with a nearby university has allowed Peridot to significantly expand its knowledge-base and utilize world class resources in engineering and manufacturing systems. Success is not solely based on a type of machine, a single contact, or luck; but with a talented team of people that believe in what they do and share a passion for providing a solution to benefit a customer. This is the basis of Peridot’s success – from its experienced technicians and engineers to its partnership of dedicated manufacturers’ sales reps that do an excellent job of representing Peridot’s services and capabilities.

At its roots, Peridot is an advanced manufacturing and supply chain company. Whether you’re an entrepreneur with a start-up idea, a company with a specific prototype project, or a blue chip company needing a solution to a full program – if you have a challenge or a new product innovation needing a solution to produce that product, Peridot has a very strong shot at being your complete turn-key solution. Looking to the future, Hockemeyer states, “I’m confident that the opportunity is there, the customer base is there that needs our products and services. We simply need to be aggressive in getting the word out. Partnering with a company like ours is becoming more important to OEMs because the marketplace is using technologies like we’re offering to get from concept to production much faster.”

In closing, Hockemeyer beams with a bit of pride when he mentions, “At Peridot, we not only have a relaxed atmosphere to work, but the diversity of solutions we have available to offer our customers makes for a fast-paced and ever-changing day. That’s the culture we promote to people we’re bringing on-board and that’s what gets me and the wonderful team we have here, our Peridot family, up and moving every morning. You never know what the next day will bring. And we do like to have fun along the way.” So, it appears evident this small town tale of life lessons, faith, and teamwork is far from over, since Peridot has plenty of innovative solutions yet to offer its customers for years to come.

AT A GLANCE

WHO: Peridot, Inc.

WHAT: A full-service product development service bureau

WHERE: Hoagland, IN

WEBSITE: www.peridotinc.com

PREFERRED VENDORS

Hoosier Pattern – hoosierpattern.com

Hoosier Pattern’s vision firmly believes that innovation drives productivity. We understand that industries are evolving, and staying up-to-date with the latest technological advancements must always remain our highest priority. With our cutting-edge CNC manufacturing and rapid prototyping practices, we provide manufacturing solutions for businesses throughout the Midwest, United States, and all over the world, all with the highest-quality foundry tooling and 3D printed sand that our industry demands.

At Hoosier Pattern, we invest heavily in our technology. As of 2020, we are one of the only service providers to own and operate multiple 3D sand printers in house. In addition, we have added a 5-axis machining center, three Doosan machining centers, one Doosan 4-axis horizontal machining center, and a robotic milling cell for sand molds.

We understand our customer’s demand for expedient delivery times, and product excellence is a must, and this expectation is our driving force behind our day-to-day operations. We have always been committed to “On Time Delivery” to keep up with the strict timelines of our customers. With our 3D sand printing process, customers can expect a 10-day turnaround time on many of our projects with the ability to ship out quicker if needed. With the addition of a 4th in-house printer it will allow us the flexibility and capacity to keep up with customer demands. Both foundry tooling and 3D printed sand follow all of Hoosier Pattern’s rigorous quality-control systems throughout each stage to ensure the industry’s highest possible standards. At Hoosier Pattern we win, when you win.