Supply Chain Innovation

Trends to Watch in 2023

With COVID behind us navigating supply chain logistics becomes paramount

Supply chains continue to experience rapid change and constant evolution. Many organizations have responded by perfecting the fine art of the pivot; others discovered solutions to help them better manage disruption and risk. Coming in 2023, the primary focus of networks across the globe will be converting available data into useful knowledge.

The ASCM Research, Innovation, and Strategy Committee (RISC) has just announced its annual list of supply chain trends to watch. Each member of this committee spends months reviewing the literature, discussing potential topics and rigorously scoring each trend using an exacting methodology. All trends are then aligned to the seven primary processes of the benchmark SCOR Digital Standard (SCOR DS): orchestrate, plan, order, source, transform, fulfill and return.

In the ultimate top 10, a few trends have had staying power since 2022, but there are some key new topics that supply chain professionals must be aware of. These include advances in data analysis, an increased focus on resilience, and an emphasis on sustainable business practices.

The number-one trend for 2023 is big data and analytics, which aligns most closely with the planning stage of the SCOR DS benchmark. The topic of data analysis in the supply chain has been consistently perceived as an important trend, as the rapid growth of technology is a boon to data collection. Delivery services, inventory analysis, social media platforms, third-party cloud platforms, the internet of things, and business transactions are all providing business leaders with vast amounts of data; however, organizations still need to sort and analyze it, which is where advanced analytics and automation come in.

For example, supply chain analysts point out that advanced data analytics and artificial intelligence (AI) tools can predict a range of unexpected disruptions and improve demand forecasting. For example, there has been a lot of concern over the past few years about a shortage of semiconductors, due to a dearth of manufacturers and the expense of materials, among other reasons. According to a recent article published by CNBC, semiconductor distributor Rand Technology uses AI to connect customers with a supply surplus to potential buyers. It also employs advanced analytics to spot trends, such as price increases or production change notices, and determine how much buffer stock a buying company might want to secure.

Furthermore, big data helps coordinate supply chain planning and execution, improving visibility for customers and giving them more power over what they buy and when — information that is crucial up the supply chain. Finally, advances in predictive and prescriptive analytics, big data, algorithms, and robotics will have broad-reaching effects on all organizations wishing to achieve a more agile, resilient supply chain.

Critical in both the plan and source phases of supply chain management, resilience will continue to be a focus over the next year. According to the ASCM Supply Chain Dictionary, resilience is the ability to return to a position of equilibrium after experiencing an event that causes operational results to deviate from expectations. Furthermore, resilience is improved by either strategically increasing the number of response options or decreasing the time to execute those options.

Critical in both the plan and source phases of supply chain management, resilience will continue to be a focus over the next year. According to the ASCM Supply Chain Dictionary, resilience is the ability to return to a position of equilibrium after experiencing an event that causes operational results to deviate from expectations. Furthermore, resilience is improved by either strategically increasing the number of response options or decreasing the time to execute those options.

Resilience has been top-of-mind for a while: Businesses reacted to the disruption initially caused by the pandemic by quickly pivoting to producing alternative goods, finding new vendors, or increasing prices to keep up with rising costs and more demand. With the effects of the pandemic still ricocheting around the world, businesses are looking to shorten their supply chains even more to prevent disruption by political unrest, climate crises, or worker shortages.

One way networks are reacting to ongoing change is by focusing on onshoring or nearshoring: By collaborating with increasingly local vendors, businesses discover the many benefits of manufacturing and producing their products closer to the end customer. And the certainty of obtaining goods and meeting customer demands in the shortest amount of time tends to outweigh any inherent cost increases related to more transparent business practices.

For instance, the Lego Group, the ubiquitous toy brick producer based in Denmark, is building a new factory in the United States, with the goal of shortening lead times for production. The company already has factories all over the globe, to supply nearby markets with the toys at a rapid rate. Its nearshoring strategy proved its worth during the pandemic: Profits doubled in the first half of 2021 when many people were in lockdown and others were staying home to keep safe and needed an activity to keep them busy. Although this plan has been in the works at Lego for years, the state of the supply chain today — including skyrocketing energy costs, greater risk, and increased complexity — has forced many organizations to consider nearshoring as a method of boosting resilience.

Another technique, redundancy, is gaining momentum. Dirk Holbach, chief supply-chain officer for Henkel’s Laundry & Home Care business unit, told McKinsey: “We manufacture a certain product technology in two locations so that we have a backup. If one location goes down, at least I can manage the supply for a couple of weeks. We cannot replicate capacity ad infinitum, but that is one very simple principle.” If a major weather event or other crisis affects one facility, the second one is ready to start supplying goods to consumers, limiting delays down the line.

Supply chain professionals have witnessed firsthand how redundancy, nearshoring, and other methods of building resilience can prevent disruption in the supply chain, and they’ll continue to expand these processes into their networks in the coming year.

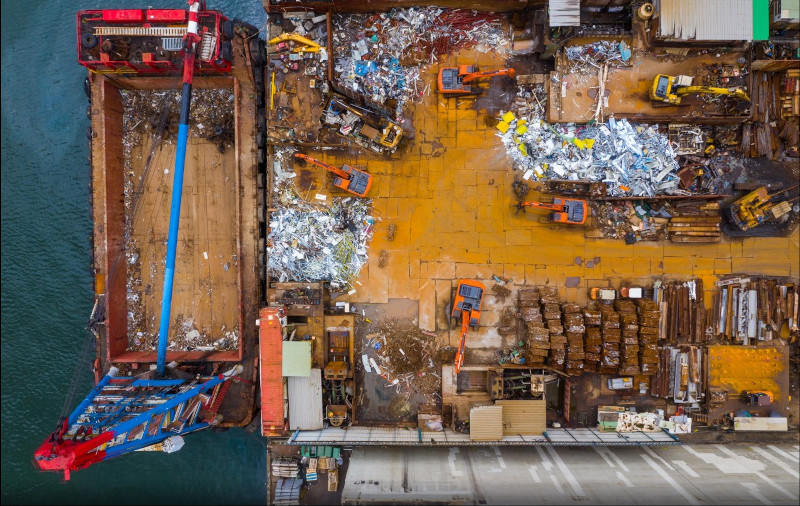

The days of the traditional linear business model — “take, make and throw away” — are officially gone. Not only do these wasteful practices harm the environment, but they’re also incredibly wasteful, costing businesses and consumers money. Circular business practices and models have been rising in popularity and are more important than ever going forward.

Although recycling has been a consumer buzzword for decades, it’s not a way forward. In the past few years, China stopped accepting trash and recyclables from Western countries, leaving the United States and other rich countries with nowhere to import their garbage. The truly sustainable way for businesses to cut costs and environmental impacts is to reduce waste by innovating their designs and production processes.

According to the CEO of Coreo, Ashleigh Morris, in an interview with ASCM, “A circular economy is made up of three ideas: Firstly, it designs out waste and pollution from our world. Secondly, it keeps products and materials at their high value for as long as possible. And finally, it regenerates our natural systems.”

For example, it’s becoming increasingly difficult to find the rare minerals needed for high-tech goods such as semiconductors, electric vehicles, fiber optic cables, and solar panels — products that have grown in popularity as technology has advanced and environmental concerns have increased. But excessive waste during the manufacturing process, especially of minerals such as neodymium, contributes to its rarity. By rethinking how organizations use the minerals in production — high on the make scale in the SCOR digital standard — companies can limit waste and pollution and keep more of the raw materials for additional products, increasing sustainability and reducing costs.

These three trends are just some of the massive changes that businesses are encountering in their supply chains, and they will continue into 2023 and beyond. But perhaps the most important takeaway is this: All supply chain shifts require competent and capable people, who can maximize opportunities, overcome challenges and ensure everyone contributes to their fullest potential. As is always the case, a supply chain’s talent is its most valuable resource. To learn more about how ASCM equips industry professionals for whatever may come their way, as well as these and other trending topics, visit ASCM.org.

AT A GLANCE

ASCM Association of Supply Chain Management

What: largest organization for supply chain and the global pacesetter of organizational

transformation, talent development, and supply chain innovation.

Where: Chicago, Illinois

Website: https://www.ascm.org/