The full promise of 3D metal printing is imminent as long-sought quality-control systems provide newfound ability to scale additive metal manufacturing. From its inception by scientists at Los Alamos, Sigma Labs Inc. has led the world in developing software that addresses serious quality-assurance issues in 3D metal printing. Now the company has moved from beta development and third-party validation to commercialization in an untapped $2 billion market as the only known provider of in-process, quality-assurance software to the commercial, 3D-metal-printing industry able to work across the majority of printers.

A Global Transformation

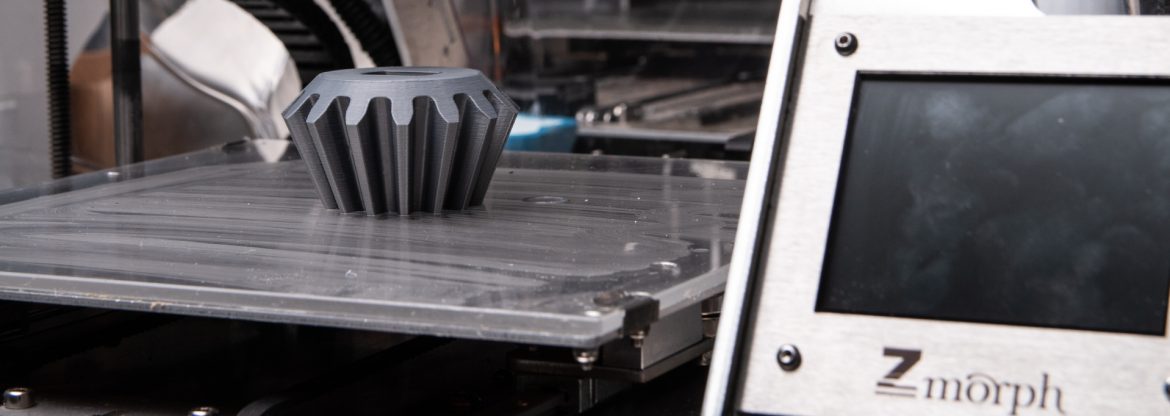

The world is entering what many have dubbed the fourth industrial revolution. This transformative period is being built upon the widespread availability of digital technologies that were the result of the third industrial, or digital, revolution. The fourth industrial revolution is being driven largely by the convergence of digital, biological, and physical innovations, many of which are now occurring in additive manufacturing (AM).

The World Economic Forum estimates the value of this transformation at an eye-popping $100 trillion across all sectors in just the next 10 years. The manufacturing sector, a primary driver of prosperity and economic growth, is a key factor in this technological tsunami, and given its ability to entirely reshape the global manufacturing sector, additive manufacturing, or 3D printing, is at the forefront of this transformation.

“Emerging technologies such as AI, robotics and 3D printing are disrupting the manufacturing industry and unlocking new ideas and potential that were previously unimaginable,” said Dion Weisler, President and CEO of HP Inc. during a recent World Economic Forum. “With this change comes opportunity. 3D printing, in particular, is at the forefront, given its ability to reshape the sector.”

3D Dilemma

Despite the potential, a myriad of variables from machines to materials creates production challenges in additive manufacturing. Aerospace, defense, auto makers, and biomedical have all embraced the potential of 3D metal printing but have been limited by the inability to completely understand and control the 3D-metal-printing process, which has led to excessive costs and inability to scale production.

One of the primary impediments preventing 3D metal printing from being fully embraced and displacing traditional manufacturing has been quality-control issues. Manufacturers can’t be certain each newly formed metal part meets precise specifications in every layer of a 3D part and have been forced to rely on costly and time-consuming postproduction inspection techniques. The inability to know the quality of finished products until postproduction and the uncertainty of parts being produced with consistency has severely limited the widespread adoption of additive manufacturing. Due to these limitations, 3D metal printing has been mostly relegated to prototyping — until now.

Sigma Labs Inc. removes any uncertainty by providing quality assurance during the printing process rather than after, or post process. Sigma’s PrintRite3D uniquely leverages thermal signatures to monitor the quality of each part in the production process, layer by layer and in real time, using artificial intelligence to predict flaws in the melt pool during production.

This approach allows machine operators to correct or stop production of a defective part, which results in reduced error rates and higher yields. The sector has been searching for proven tools and techniques to improve quality, cut costs and scale production. This incredibly sophisticated and powerful technology holds tremendous value for the 3D-metal-printing industry.

Changing the Landscape

“We may know the specifications of the raw materials used, but we still have limited knowledge of how those materials are changed through the AM processes,” stated a recent Forbes article that featured Sigma Labs. The article further explained, “While legacy manufacturing techniques have decades, or even centuries, of scientific study into all the physical characteristics of what they produce, the new forming methods of AM have, at best, very incomplete data.”

The advent of Sigma Labs’ revolutionary PrintRite3D software changes the landscape, not only providing needed data but also delivering the ability to control the process to ensure the quality of each layer of every part during the additive manufacturing process. Sigma’s technology is real-time metallurgy, providing assurances that the microstructure of the metal is precise and meets exacting specifications.

Using AI, Sigma’s software can, over time, determine the signature of metal structural flows, monitoring for multiple variables such as proper laser sintering or warpage, thus providing manufacturers the quality assurance they need to scale production and fully commit to additive manufacturing.

“We provide quality assurance in-process rather than post-process,” said Sigma Labs Executive Chairman Mark Ruport. “Think of it as akin to a CT scan of the part while it’s being made.”

Monumental Move to Commercialization

In an industry-first collaboration, Sigma Labs recently announced a joint sales agreement to commercialize SGLB’s PrintRite3D technology, which has been integrated with the Materialise Control Platform. A recognized global leader in 3D printing software, Materialise provides the widely used Materialise Control Platform (MCP), an embedded hardware and software solution that provides better control over the AM process by giving full control to the end user. Sigma’s software is the missing element, providing much-needed controls for quality assurance.

This joint agreement not only validates the efficacy of SGLB’s quality assurance software, it also establishes commercial viability. “We’re coming out of a long stretch of testing and validation,” said SGLB president and CEO John Rice. “We’ve said that 2020 is the year when we finally take advantage of all that, and this announcement is a reflection of that.”

The partnership with Materialise marks a noteworthy opportunity for Sigma Labs. Materialise incorporates three decades of 3D-printing experience into a range of software solutions and 3D printing services, which together form the backbone of the 3D-printing industry. Now that the two companies have achieved integration, they will offer a unique product solution for retrofit of existing machines, OEM machine integration and closed-loop control.

“Growing our partnership with Materialise is a significant milestone for Sigma Labs as we expand our footprint in the market and add momentum to our quest to broaden industry access to our groundbreaking PrintRite3D software,” said Ruport. “The alignment is a natural step for both companies, as Materialise has a strong presence in the additive-manufacturing market and a reputation for quality products. Commercializing and jointly selling this integrated solution will benefit both companies as well as advance the forward momentum of innovation in the 3D manufacturing industry.”

SGLB is in an enviable position with a market projected to exceed $2 billion, based on just the estimated number of 3D metal printers shipped in the past few years. What’s even more striking is that there is no known competition for that $2 billion market. Sigma Labs appears to be the sole provider of real-time, in-process, quality-control software for the metal additive manufacturing market, capable of running on the majority of metal printers in the market, on single, dual, or quad laser machines. Beyond the huge existing market, 3D printing is booming, projected to grow at a CAGR of 32.5% from 2019 to 2024, and Sigma should be able to ride the crest of that wave as well.

A large untapped market in search of solutions, a significant technological head start, strategic partnerships and alliances in place, multiple patents already awarded with more pending and the sole provider with significant barriers to entry from competition — Sigma Labs looks to be more than ready to launch commercialization and certainly appears capable of delivering the type of rewards investors dream about. With the availability of critical quality-control systems now in place, the untapped potential of 3D metal printing looms large on the manufacturing horizon.