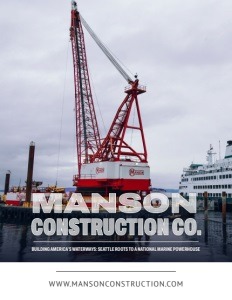

Building America’s Waterways:

Seattle Roots to a National Marine Powerhouse

Navigating the Leading Path in the Marine Industry

Fueled by Unparalleled Construction

Founded in 1905 as a small pile driving company in downtown Seattle, Manson Construction Co. has evolved into one of the nation’s most respected marine and heavy civil construction firms. Over more than a century, the company has remained true to its roots while expanding its capabilities to meet the growing complexity of America’s infrastructure needs.

“We started as a pile driver in Seattle,” says Ryan King, Senior Vice President of the Western Division at Manson Construction. “We expanded our capabilities into dredging in the 1970s and ’80s, and then hit a pretty big growth spurt in the late 1990s and early 2000s with our involvement on the Bay Bridge alongside Kiewit and Flatiron.”

That project marked a turning point, establishing Manson’s reputation for executing large-scale civil and marine works with precision and integrity. “Our civil group has been building significant infrastructure ever since,” King says.

Navigating America’s Waters

Manson’s reach is national, with projects stretching from the Pacific Coast to the Gulf of Mexico, in the Pacific Islands and along the Eastern Seaboard. The company’s ability to mobilize complex marine equipment wherever needed defines its operational flexibility.

“Our markets, in a nutshell, are anywhere you can navigate a derrick barge to navigable waters in the United States,” King explains. “We have a strong presence on the West Coast, in the Gulf of Mexico, and around Florida and the East Coast.”

While regional conditions differ, Manson’s operational philosophy remains consistent. “The regulatory requirements are slightly different in all locations, but they’re very similar,” King says. “We really try to understand what those requirements are, and we don’t take any shortcuts. We treat every project by the strictest standards so that we’re consistent, whether it’s on the Gulf Coast or the West Coast.”

Engineering with Precision: The Port of Alaska

One of Manson’s recent major undertakings demonstrates both the technical and environmental complexity of marine construction. The company has completed the first phase of removing sheet piles at the Port of Alaska—an intricate project that involves dredging and removing structures built decades ago.

“The nature of the work was very unknown,” King recalls. “We were pulling sheets and dredging, removing what was built previously, and there were a lot of unknowns there.”

Facing these challenges required foresight, collaboration, and a strong emphasis on planning. “We were very diligent in working with our designers to come up with a plan to remove the sheets and dredge in sequence patterns that made sure it was safe for everybody,” King explains. “The biggest factor was strong planning and a strong understanding of how the wall and the earth behind it would react as we took different steps. We made sure we had a strong design and a strong quality control presence to ensure we followed our plan.”

A Culture of Safety, Quality, and Leadership

Behind every project at Manson is a workforce grounded in safety, quality, and growth. King says fostering a collaborative safety culture is not about rules but engagement.

“Being safe isn’t a bunch of rules and compliance,” he says. “It’s about having our craft and staff both involved in how we’re going to execute work safely, planning work together, and creating the best possible environment we can.”

That approach begins with a comprehensive safety program and extends into planning and training. “It starts with a quality safety program,” King says. “Then we make sure we have high-quality work plans so our folks can build at the highest level with a plan in front of them. We also invest time and resources to train our people—whether it’s safety, leadership, or technical skills—so they’re qualified and growing their careers.”

Collaborative Methods, Proven Outcomes

With coordination at the forefront, Manson embraces collaborative construction methods, including design-build and Construction Manager/General Contractor (CMGC) approaches.

“Design-build is a great method,” King says. “It allows us to work with our designers to come up with a plan that fits our tools and people, while also fitting what the client needs.”

Manson’s CMGC projects also deliver strong results. “We come in early and help the client get to 35 percent drawings,” King explains. “We work through costs and risks together. It’s great to go into a project knowing we’ve discussed all the risks transparently. They save money, we eliminate risk—it’s a win for everyone.”

Blending in-House Expertise with Trusted Allies

Manson’s broad scope requires deciding which work to self-perform and which to subcontract. “We try to self-perform everything we know how to do, but we also know we’re not experts at everything,” King says. “If we’re not using a derrick barge, our equipment, or our people, we’ll find the right specialty subcontractor—foundation, electrical, or mechanical—to do the job.”

When selecting partners, Manson looks beyond price. “We consider region, expertise, pricing, and how involved they’ll be in our plan,” King explains. “It’s not just about who’s cheapest. We want the right combination of skill, commitment, and collaboration.”

A standout partnership is Manson’s long-running collaboration with Silverado, a Bay Area demolition contractor. “We’ve done a lot of jobs together demolishing piers and wharves over the last ten years,” King notes. “We’ve really figured out how to work well together, each finding our place and supporting one another.”

Community Commitment Beyond the Worksite

Manson’s culture of partnership extends into the communities where it operates. “We have a very active employee engagement program,” King says. “We’re actively looking for ways to support our employees in the things they do in the community, whether it’s a Ronald McDonald House fundraiser or building a home somewhere. We challenge our staff to present ideas, and our executive leadership usually supports them financially or with time during work.”

Recognized for Excellence

Recognition for outstanding collaboration and execution has followed the company across multiple projects. “ We’ve received five partnering awards across two recent projects at Naval Base San Diego, including the AGC’s coveted Marvin M. Black Partnering Excellence Award,” King shares proudly. “It’s a combination of a great client, a great project team, and people working together to solve issues every day. I’m proud of it because it’s all about partnering and collaboration, and that’s something we do very well.”

Confronting the Industry’s Greatest Challenge

Like many construction firms, Manson faces a major challenge in workforce recruitment. “The biggest challenge is finding people to staff the projects and professional craftsmen to build them,” King says. “There’s a lot of work in the marine industry, especially in the Pacific Rim, but finding enough people to manage and build it all is difficult.”

King attributes this shortage to a cultural shift. “There used to be more folks who went into trades,” he reflects. “Now, many of those people are going to college or into tech instead. It really is a great career—it’s rewarding to know you built something for your country and community. I take great pride in showing my kids the bridges and wharves we’ve worked on.”

Investing in the Next Generation

To address the labor shortage, Manson is taking proactive steps to engage young people and introduce them to opportunities in marine and civil construction.

“We go to local high schools and have a strong program in the Bay Area,” King explains. “We’re trying to get more engaged here in Puget Sound as well. We attend college functions—it’s partly recruiting, but it’s also about educating people. We sponsor and attend career fairs to talk about our great business.”

By emphasizing the tangible rewards and lasting impact of construction work, Manson hopes to inspire a new generation to pursue careers in the trades.

Innovation in Grounded Experience

Looking ahead, Manson is focused on integrating technology to enhance safety, efficiency, and collaboration without compromising the human expertise that defines the industry.

“It seems like the industry answer is always technology, but it’s true,” King says. “We’re really learning how to apply it to our business. Construction has been doing things the same way for a long time, but we’re getting in line with new technology and figuring out how to make our business more efficient—and more engaging for the youth coming behind us.”

As technology reshapes everything from project modeling to site safety, Manson’s approach balances innovation with the people who bring projects to life. “You can’t over-rely on technology,” King notes. “It always comes down to the people who know how to do the job. But technology can clear a lot of the busy work and help us focus on what really matters.”

Building the Future, One Project at a Time

From its origins as a small pile driving company in Seattle to its status as a national leader in marine and heavy civil construction, Manson Construction has remained steadfast in its mission—to deliver exceptional work through integrity, teamwork, and safety.

The company’s story is one of continual growth, adaptation, and a deep respect for the people who make its success possible. As King reflects, the pride in building something lasting remains the driving force behind Manson’s work.

“It’s rewarding to know you built something for your community,” he says. “That’s what keeps us going.”

AT A GLANCE

Who: Manson Construction Co.

What: A nationally recognized marine and heavy civil construction company based in Seattle, known for building and dredging central waterfront, bridge, and infrastructure projects across the United States.

Where: Seattle, Washington

Website: wwww.mansonconstruction.com

PREFERRED VENDORS/PARTNERS

Michels: www.michels.us

Established in 1959, Michels completes some of the world’s most challenging energy and infrastructure projects. We serve customers in the energy, renewables, foundations, marine, mission critical, trenchless, and water and wastewater industries. With 7,000-plus people and 18,000 pieces of equipment, Michels provides tailored solutions for end-to-end design and construction.

Granite Construction Inc.: www.graniteconstruction.com

Granite is America’s Infrastructure Company™. Incorporated since 1922, Granite (NYSE:GVA) is one of the largest diversified construction, construction materials, and full-suite civil construction companies in the United States, delivering infrastructure solutions for public and private sector clients throughout the country. Granite is an industry leader in safety and an award-winning firm in quality and sustainability.

American Piledriving Equipment (APE): www.americanpiledriving.com

American Piledriving Equipment, Inc. (APE) headquartered in the Seattle area, is a global leader in deep foundation equipment and creator of the world’s largest pile drivers. With branches and talented technicians throughout Asia and the Americas, APE powers projects worldwide. Go Deep!