e-Zinc

Storing electricity in metal

Business View Magazine interviews James Larsen, CEO of e-Zinc, for our focus on the Ontario Clean Technology Industry

As the world moves towards adopting renewable energy as its primary energy source, one emerging concern is energy storage. While current batteries, mostly built around lithium-ion technologies, are playing an integral role in the transition, their limitations aren’t sufficient to enable a full-scale transition to renewable energy.

The main challenge with current battery technologies is that they fall under the short-duration energy storage (SDES) spectrum, lasting four hours or less per charge. In terms of grid-level energy requirements, they are not a viable replacement for coal and diesel plants. What is a viable replacement is the holy grail of clean energy tech, long-duration energy storage or LDES, which, in theory, should deliver energy for 24 hours to several days on a single charge. Pundits believe such batteries, supplied at scale and affordably, will completely replace fossil-fuel-powered power plants.

Leading the charge into this bold future is e-Zinc, a red-hot Canadian startup currently on a fundraising spree that has developed a zinc-based LDES battery solution that might just tip the balance towards full-scale renewable energy adoption.

James Larsen, CEO

“The late Dr. Xiaoge “Gregory” Zhang, who was a Ph.D. from MIT and Columbia, founded e-Zinc in 2013,” says James Larsen, CEO of e-Zinc. “Before founding e-Zinc, Dr. Zhang worked at Teck Resources as Manager of R&D for 20 years. Owning one of the world’s largest zinc mines, the company tasked him with identifying opportunities in the energy storage sector that could create demand for the metal. Having worked with zinc for over two decades – he even wrote the world’s only book on the subject matter – he realized that zinc has an incredible set of characteristics to be an energy carrier.”

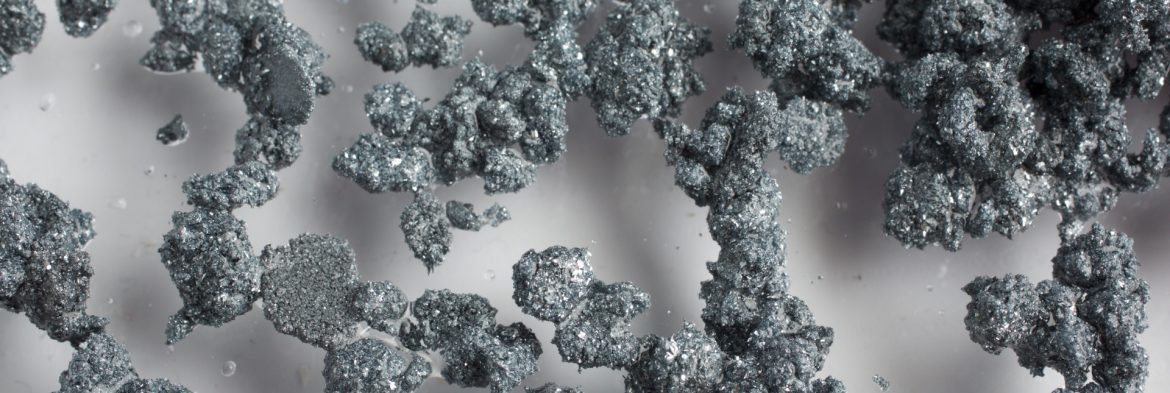

At the time, zinc-based batteries were designed as another short duration system, like lithium-ion or lead-acid. However, Dr. Zhang figured out a way to store energy in physically-free zinc metal, unlocking the ability for economically viable long-duration storage. This discovery was the impetus to start e-Zinc, which Dr. Zhang founded and led for the first five years, culminating in the completion of its first successful laboratory demonstration of the functionality and electrochemistry of the technology.

The next step in e-Zinc’s journey was to start commercializing the technology, and this required an expanded executive team that would lead fundraising efforts. “I was hired as the new CEO to lead the commercialization of the technology, and our first order of business was raising money,” Larsen shares. “We closed a $3.5 million seed round in 2019, and we were also very fortunate to win a string of competitions and grants totaling about $7 million.”

The company’s two notable wins were Breakthrough Energy Solutions Canada, backed by Bill Gates’s Breakthrough Energy Ventures, and a global solicitation for non-lithium battery technologies by the California Energy Commission. Besides these wins, e-Zinc has attracted an A-list list of investors, including Toyota Ventures and Italy’s Eni, alongside lead investor, US-based Anzu Partners.

“The investors we have are a dream syndicate,” notes Larsen. “Our partnership with Toyota gives us access to their manufacturing and supply chain expertise while Eni will give us strategic downstream capabilities as we deploy our technology.”

With so many investors lining up to hand e-Zinc fistfuls of money, how interesting can a small battery startup be? According to Larsen, very interesting, and it all comes down to the technology they have developed.

“If you’re running your laptop or cell phone at full capacity, it will only last a few hours. Our technology lasts multiple days,” he explains. “The significance of this difference is that as the world moves towards deeper penetrations of renewable energy on the grid, there will be a commensurate increase in the duration requirement of energy storage assets on the grid. The more renewables you have on the grid, the longer the duration of storage you require on the grid. Batteries, which are good for a few hours, are excellent for our needs today, but will not be able to help us achieve the deep decarbonization goals of the future.”

These statements are backed by scientific studies published by MIT Technology Review and the Long Duration Energy Storage Council. The MIT report found that California would need 20 times its existing energy storage capacity when it achieves its 50% renewables target. More strikingly, it’s predicted that the state would require 4,000 times the existing energy storage capacity by 2045, once renewables account for 100% of the energy system.

In addition, Larsen notes that other studies indicate that once renewable energy penetration crosses the 60% threshold, grids will require tens to hundreds of hours of storage. He reports, “California, one of the most advanced renewable markets globally, is at around 50% and is on course to reach the threshold by 2026. This was part of the impetus for their global solicitation for non-lithium batteries, which we happened to win. They know the big switch to renewables is imminent, and they need technologies to support this transition.”

e-Zinc currently has a team of 25 and is actively recruiting to double its team this year. Top on the team’s agenda is getting the word out that there is a new battery in town, which it is doing with the help of partners like the Zinc Battery Initiative. “ZBI is doing a lot to promote zinc batteries,” says Larsen. “For example, they commissioned a study on the sustainability of zinc, including its recyclability and reusability.”

Sustainability is a seldom held, yet critical discussion about batteries. For instance, zinc is the 24th most abundant element in the world, found in zinc, copper and lead mines worldwide, while lithium lies 33rd on the list. “A significant percentage of global lithium supply is controlled by China, Australia, and Chile, creating a triopoly that affects global accessibility and prices,” says Larsen. “It behooves us to look at a diverse source of materials, and when we look at zinc, it has an outstanding story to tell.”

e-Zinc is deploying its first fully integrated energy storage solution in Canada in partnership with Faromor, a natural ventilation company, and SunGrid Solutions, one of Canada’s leading system integrators. Although the company already has a fully functional deployment at its offices in Toronto, Ontario, Larsen sees this as a significant technical milestone.

“It will be the first time demonstrating our technology as a holistic system, incorporating the power electronics and software and controls, all connected to solar and the grid to deliver power to site,” Larsen explains. “This project will demonstrate how our solution can serve various use-case scenarios, whether resilience and backup power, renewable energy generation integration on-grid, or remote/off-grid power.”

He also points out that the deployment will demonstrate some key differences between lithium battery solutions and e-Zinc’s zinc battery solution. He clarifies, “Two striking differences are battery size and temperature resistance. Owing to density, lithium batteries are typically smaller, making them ideal for applications like mobile phones, laptops, and EVs. Our batteries are much bigger and ideal for stationary storage systems like on a farm or behind a data center. Secondly, zinc batteries can withstand extreme temperatures with some estimates showing ranges of negative 30 to 60 degrees Celsius, although the actual range could be higher once we fully characterize the battery’s performance.”

With so much on the horizon for e-Zinc, any startup would be overwhelmed by the sheer number of possibilities. However, for Larsen and his team, containing all this salient potential in a simple growth plan offers clarity of vision.

“We think of our short and medium-term market strategies as horizons,” he explains. “The first horizon is ‘resilience’, which is a way to offer backup power effectively and economically for applications like data centers, hospitals and others currently relying on diesel generators. The second horizon is ‘remotes’, which targets off-grid applications like mining operations and Indigenous communities, who currently rely on diesel generators as their primary source of power. Although such applications may want to embrace renewables, if the sun does not shine or the wind does not blow for a few days, current batteries would not last. Our technology’s ultra-long duration offers a unique opportunity not just to mitigate the use of diesel, but to eliminate it in these off-grid applications.”

In the long-term, e-Zinc is banking on its vision-mission-oriented culture to pursue an even more ambitious goal. “Our vision is access to affordable, clean, reliable energy for all,” says Larsen. “We see an incredible opportunity to vertically integrate ourselves and become one of the few incumbents that offers one-stop-shop renewable energy solutions to customers as the industry matures.”

AT A GLANCE

e-Zinc

What: A visionary company developing electrochemical technology solutions for energy storage

Where: Based in Toronto, Ontario

Website: https://e-zinc.ca/

PREFERRED VENDORS

Naden LLC; Naden Engineering: Power Electronics & Controls Equipment

At Naden Engineering, we have a talented team of experts that specializes in the design and manufacturing of power electronics and controls equipment for commercial, defense, renewable energy and aerospace markets. One of our primary services is quick turnaround on programs with aggressive timelines, accomplished by utilizing modular design techniques, coupled with in-house capabilities for PCB, harnessing and turnkey assembly, CNC machining and product compliance testing.

We are committed to providing exceptional customer experience through reliability and consistency in service, design, development and operation. Our competitive edge is guaranteed through commitment to continuously improve our products, processes and resources in order to meet customer requirements, cost targets and timelines.

Our engineers are experts in some of the most challenging design and test requirements for power quality to meet a wide range of compliance standards (MIL-STD, DO-160, NASA/ISS, FCC and UL). We design, validate and conduct qualification programs, both in-house and external test labs to deliver products that are certified for the most demanding applications in space, commercial aviation, automotive and commercial ground equipment.

Please visit nadenengineering.com to learn more.

ISO9001:2015 Certified