Business View - October 2015 115

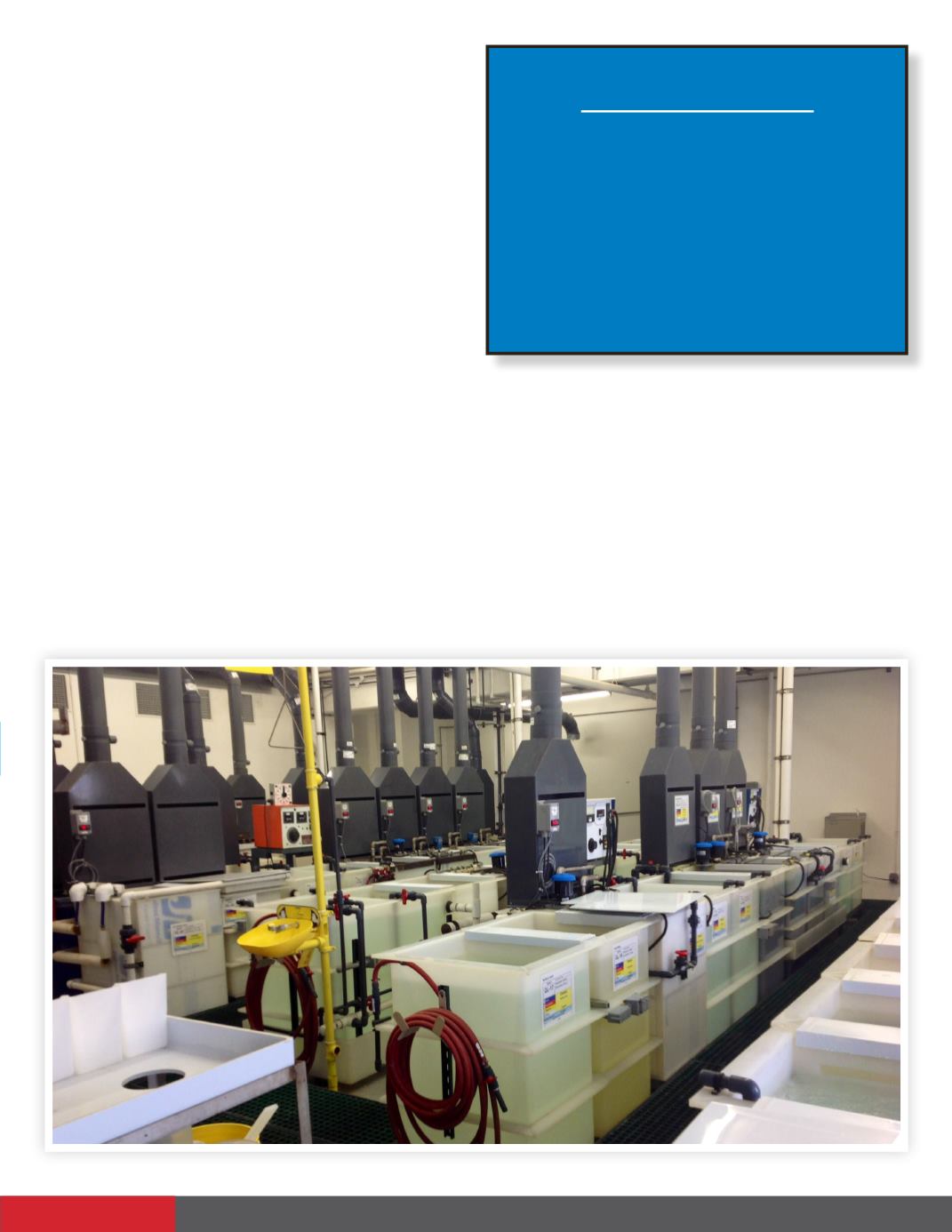

electroless nickel market. A few years later they added

aluminum anodizing.”

Today, the two companies, which have facilities about

15 miles apart from one another, are complimentary in

terms of the products and services they offer. Rick Mi-

chalec of the Business Development group describes

The Lindgren Group’s customer base: “Our customers

vary; anyone who’s working with metal is a potential cus-

tomer of ours. If they work with metal, we can work with

them – from large OEMs, down to small, mom-and-pop

machine shops. They send us product that we service

and we send it back to them.” Roberg adds: “We’re job-

shop platers – we don’t produce a product, we provide

the finish, which is critical to the application’s success.”

Ken Barnes also works within the Business Development

group. He elaborates further: “We can work with virtually

anybody. We can work with machine shops, casting facili-

ties, metal stampers; we work with recreational products,

aerospace and defense-type products, automotive, and a

whole host of commercial applications, as well. We pro-

vide 60 to 70 percent of the chemical finishes that are

available in the market. The majority of our business is

within a three to four-hour drive of either facility, but we

do have customers throughout the country. We do most

of our work in the Midwest – we’ve got customers in Kan-

sas and Michigan – but also the East coast, California,

and Canada. And because of our growth, certifications,

OEM approvals, and our national reputation, now, we do

AT A GLANCE

WHO:

The Lindgren Group

WHAT:

A recognized leader in the metal finishing

industry

WHERE:

Minneapolis, Minnesota

WEBSITE

:

MANUFACTURING