Business View - August 2015 77

Today, Epcon encompasses a 250,000 square foot,

modern, manufacturing facility on 18 acres in the

Greater Houston area, housing 8 to 10 million dollars’

worth of fabricating machines, CNC (Computer Nu-

merical Control) machines, and other automated ma-

chinery. Products are sold around the world, with sales

fluctuating between 70-80 percent domestic, and 20-

30 percent outside the US.

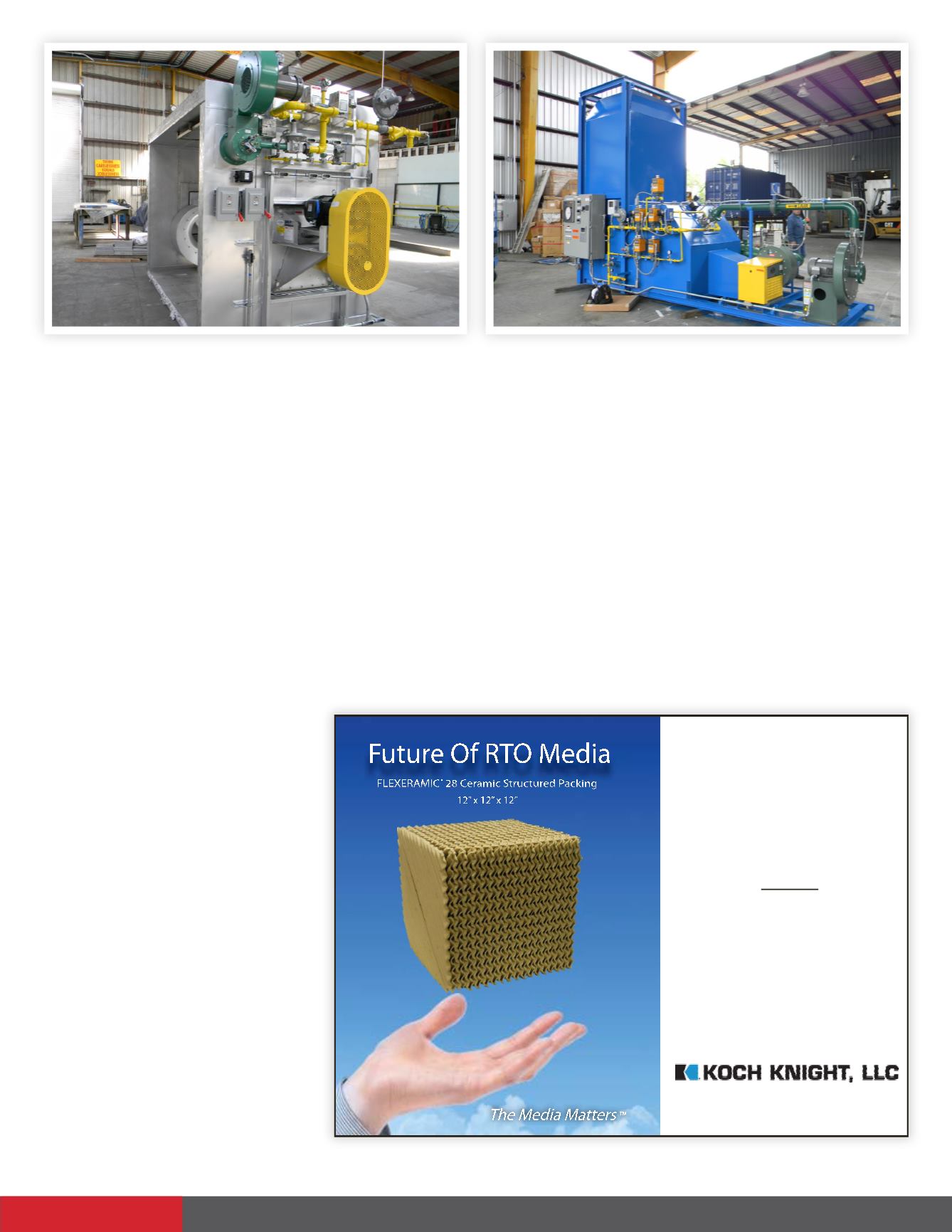

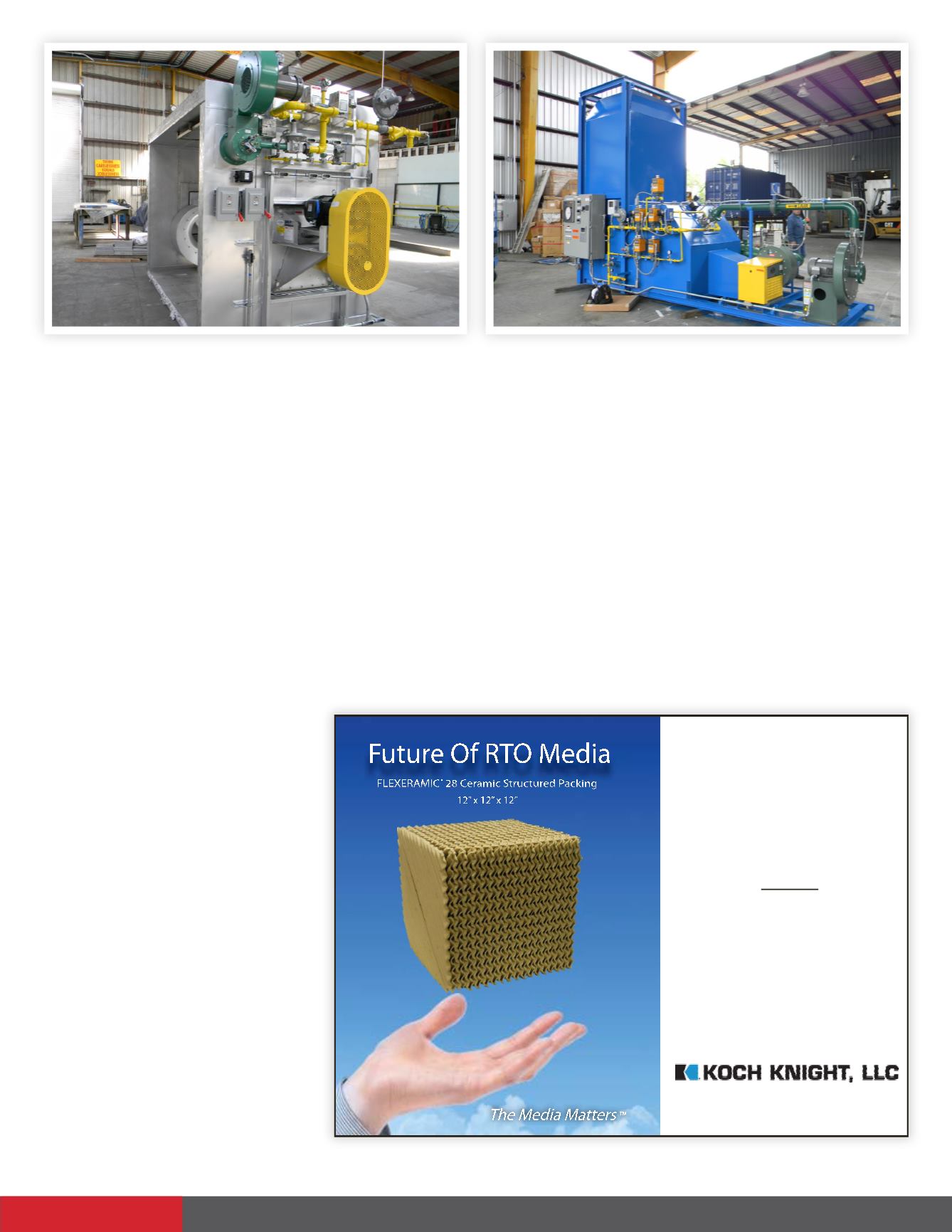

Product lines include environmental thermal oxidiz-

ers, environmental abatement systems for volatile or-

ganic compounds (VOCs), as well

as custom-designed, industrial ov-

ens and furnaces. Because of its

proven engineering expertise and

on-site manufacturing facilities,

meeting American Petroleum Insti-

tute (API) standards, Epcon is now

considered the go-to source for

these high-tech, niche products.

Customers come from the auto-

motive, aerospace, metal coat-

ings, internal pipe coating, flexible

packaging, resin manufacturing,

copper-clad laminates, industrial

finishing systems industries, and

basically anywhere that curing/

heat processing is required.

Go Green with Epcon

With a mission to “protect the environment through

technology,” Epcon is proud to be advancing in the

area of solar energy production. Its design team has

developed a procedure using existing on-site systems

for the curing and heating processes of solar panel

production - a significant achievement in its ongoing

quest to preserve our natural resources.

Air quality control is another key component of Epcon’s

green focus. Jamaluddin explains, “When the EPA was

MANUFACTURING