6

Business View Magazine

ue added there, other than, in our case, treating the

wood.”

Keeping the Competitive Edge

Since the beginning, Wheeler has reacted to potential

downturns by capitalizing on its strengths. As the world

changed, this innovative company had the foresight to

diversify and become market - rather than product –

oriented, always, putting the customer first. That mind-

set continues today.

“Most of our contractors we’ve done business with for

many years. They know our products are good and our

lead times are what we tell them. With our engineered

products, plans and chalk drawings, we add value in-

house, whereas our competitors are often lumber bro-

kers or people who can’t offer the complete package

unless they outsource. Anything that has to do with de-

sign is a selling point for us.”

Change for the Good

During the recent recession, the house truss business

suffered, prompting Wheeler to sell two of their three

facilities. It kept Kansas and, thanks to the improving

housing market, has opened a new plant in Houston.

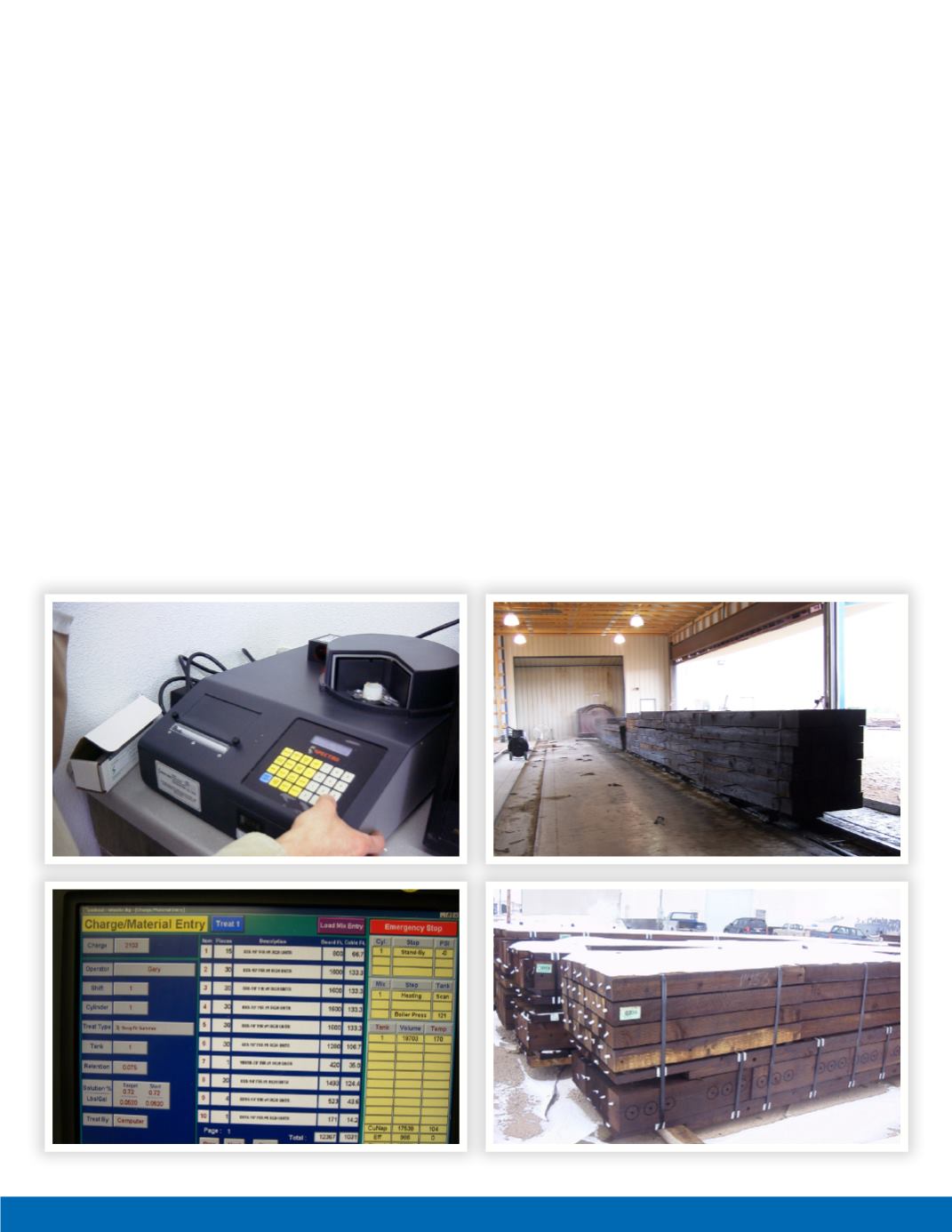

The biggest company “reface” came in 2003, when

a fire and explosion destroyed the treating plant. “At

that time, we were treating wood with creosote,” says

Parrett. “When we decided to rebuild at the same lo-

cation, we switched to copper naphthenate. This non-

hazardous chemical doesn’t have the restrictions that

creosote has; it’s oil-based, cleaner, and works just as

well. There’s been a push since 2003, to convince rail-

roads that copper naphthenate is a good alternative

to creosote. We’ve accomplished a good deal of that.”

Copper naphthenate works very well for bridge appli-

cations where there is traffic travelling underneath,