6

Business View Magazine

fer many of the same type of services that we do,” says

Barnes, “but there’s a much smaller segment of the

market that holds professional certifications like we do.

We are ISO 9001 Certified; we’re also NADCAP Certified,

which allows us to do aerospace and defense work. And

those certifications really speak to the high level of qual-

ity systems that we have in place at both facilities. That’s

really been a point of growth for our company. Auditors

prefer to deal with companies that have these systems

in place because it makes doing business with them

easier. They’re recognized standards in the marketplace

and they understand that the companies that have these

certifications really have their act together.”

NADCAP (National Aerospace and Defense Contractors

Accreditation Program) is a global-wide certification that

standardizes all the finishing processes for the aerospace

and defense sectors. “Because of our NADCAP accredita-

tion,” Barnes explains, “we’re well-suited to work with the

‘prime’ manufacturers and their supply chain.” Lindgren

also holds a Federal Firearms License and considers the

processing of firearms work a key part of its portfolio of

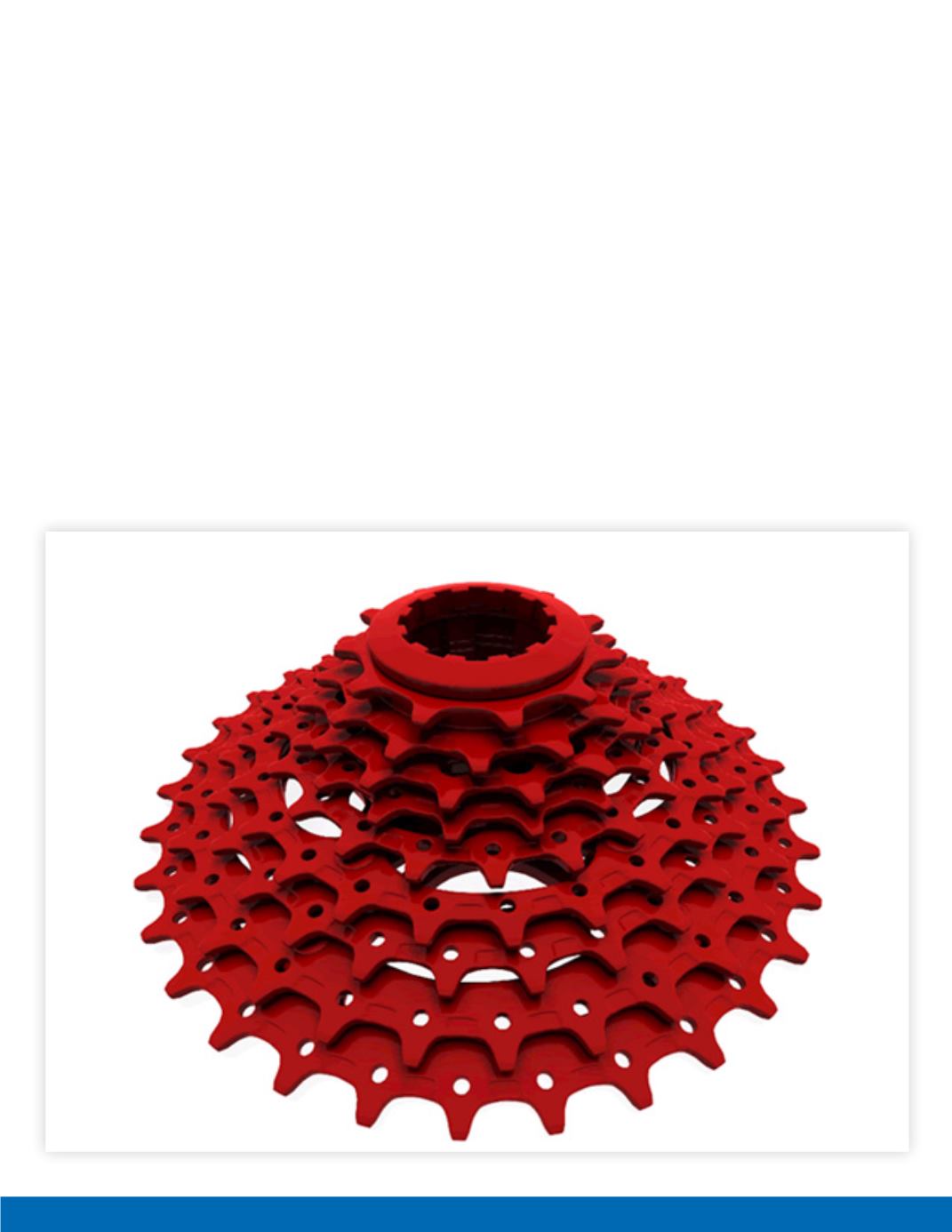

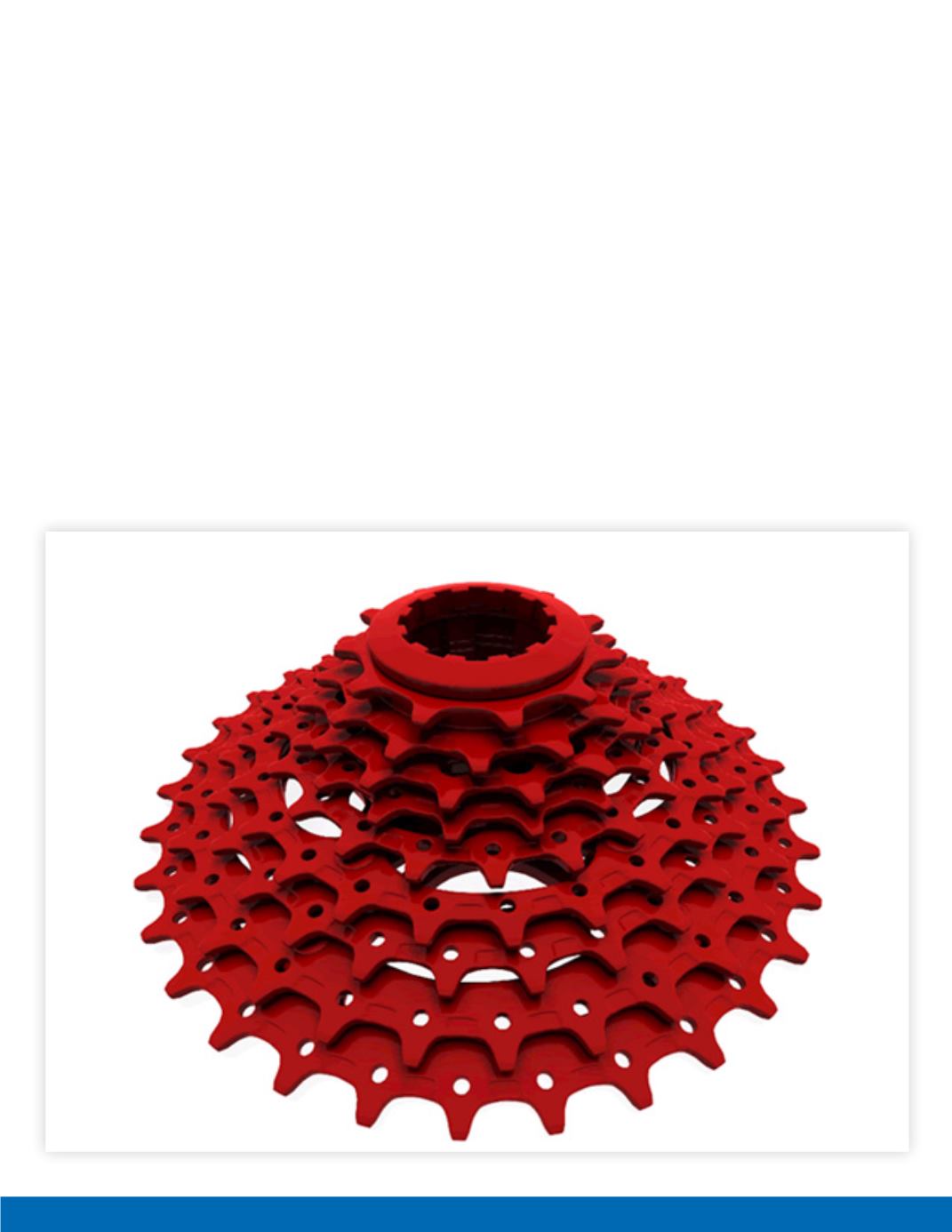

services. “We do a vast array of gun parts with a number

of different coatings,” he says. “We offer finishing from

start to finish on gun parts, including blasting, coating

options, solid film lubricants, etc. So we are a one-stop

processor for this work. That’s a really important market

to our company and one in which we’ve done a terrific job

bringing work in from all over the country.”

As The Lindgren Group moves forward, according to

Barnes, its management team is constantly involved in